Centripetal protection bearing for magnetic levitation bearing system

A technology for magnetic suspension bearings and bearing protection, applied to bearings, ball bearings, bearing components, etc., can solve the problems of poor resistance to vibration and impact, protect bearings from burning out, damage equipment, etc., and achieve the effect of high working speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

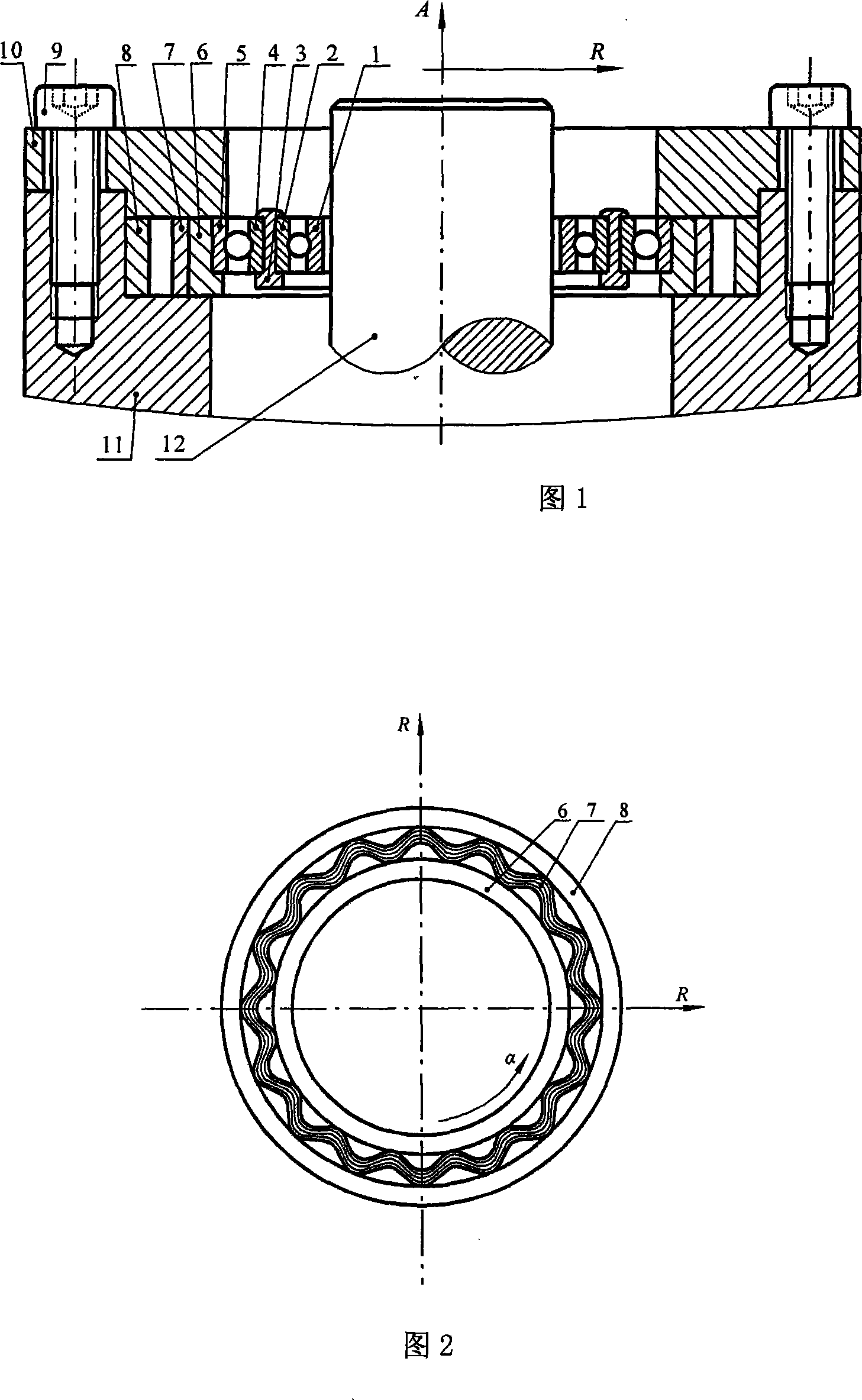

[0012] The composition, working principle and structural design of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] The centripetal protective bearing shown in Figure 1 can be used as a protective bearing that only bears radial loads in a magnetic suspension bearing system. The outer ring 2 of the first layer rolling bearing is connected with the inner ring 4 of the second layer rolling bearing through the adapter ring 3, and the outer ring 5 of the second layer rolling bearing is connected with the inner ring 6 of the radial elastic damper. The inner ring 6 of the elastic damper, the radial multilayer (3-20 layers) corrugated steel plate 7 and the outer ring 8 of the radial elastic damper are assembled together to form a radial elastic damper, and the outer ring 8 of the radial elastic damper Assembled with the inner hole of the frame 11, the protective bearing is axially pressed and fixed by the end cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com