Numerical control precise double-station grinding machine

A double-station, grinding machine technology, applied in the direction of grinding machines, manufacturing tools, optical surface grinders, etc., can solve the problems that it is difficult to meet the requirements of optical products for lens processing, the labor intensity of operators is high, and the operation action is monotonous and boring. Work efficiency and work quality, improve grinding efficiency, and reduce the effect of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

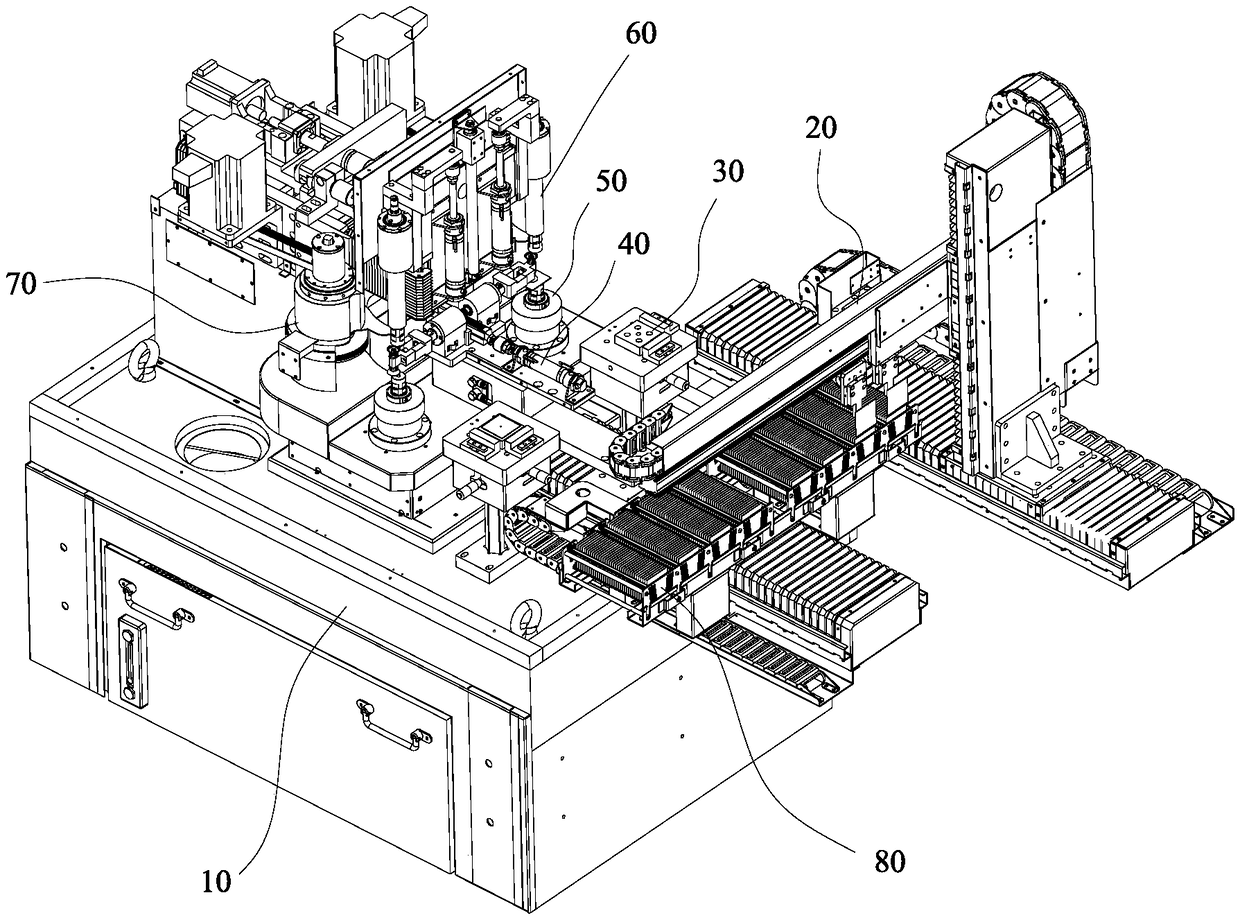

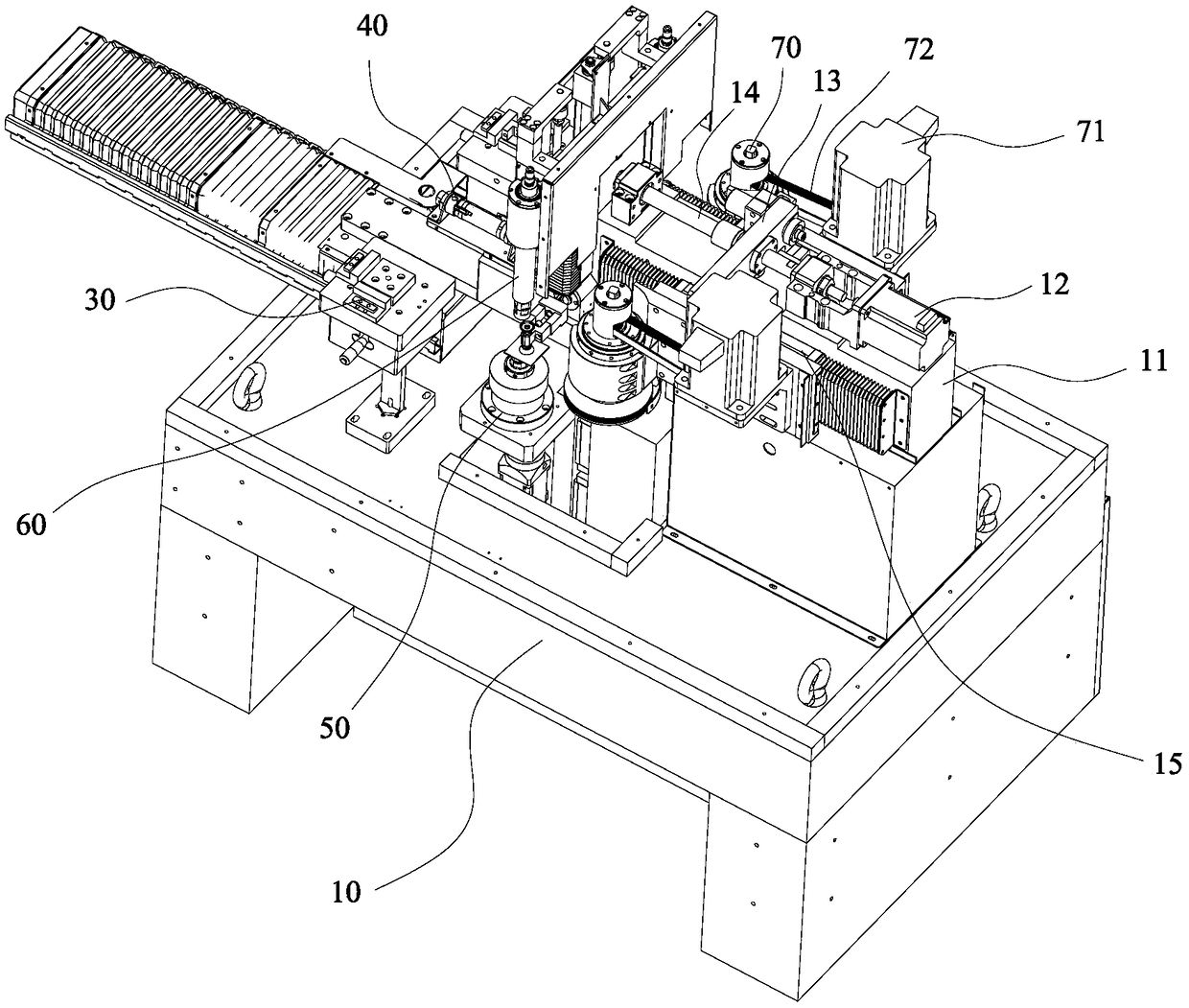

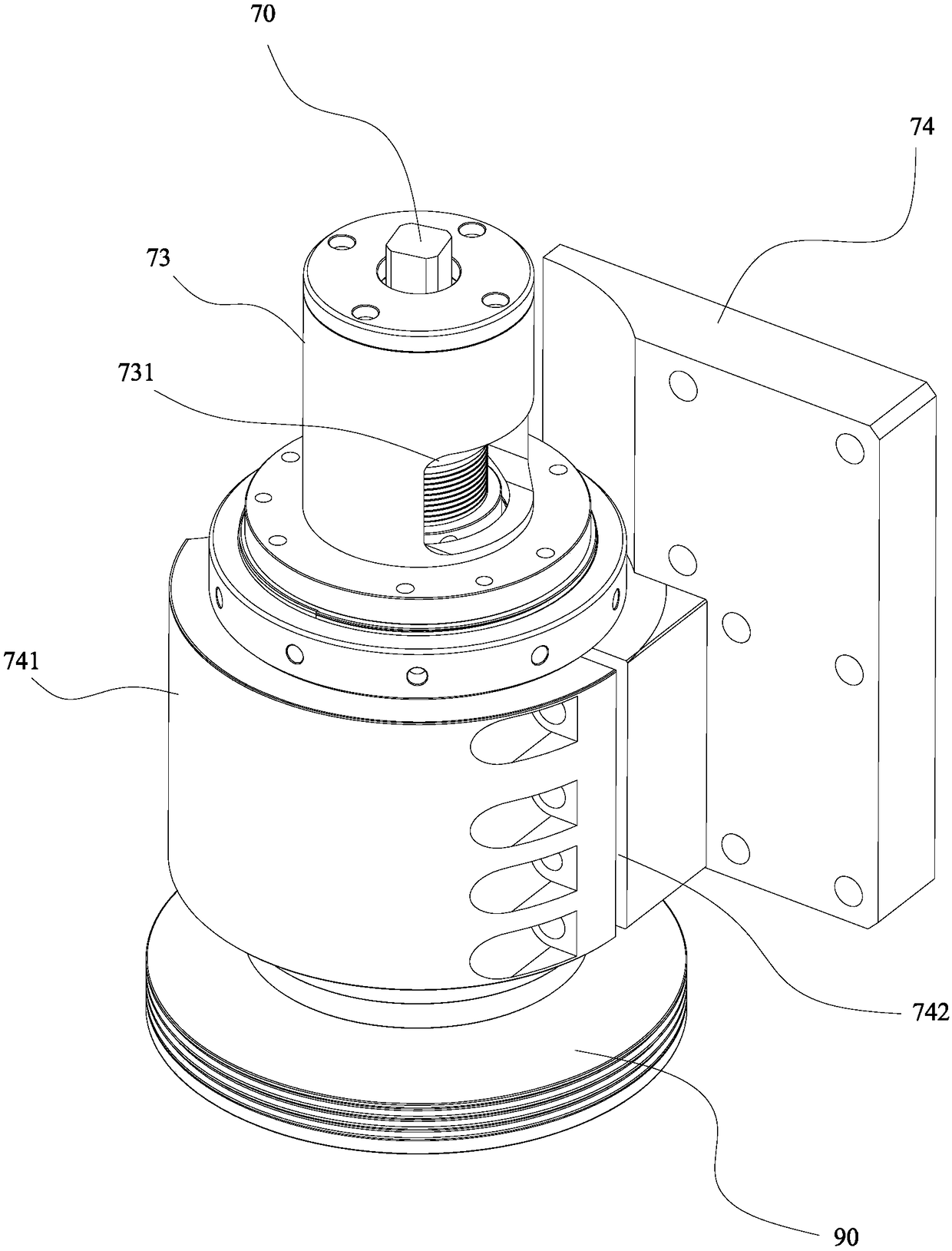

[0031] Such as Figure 1-11 As shown, a numerical control precision double-station grinding machine includes a machine base 10, and the machine base 10 is provided with a feeding mechanism, a positioning mechanism and a grinding mechanism in sequence along the lens feeding direction, and the positioning mechanism and the grinding mechanism are both There are two groups arranged side by side. The feeding mechanism includes a plurality of troughs 80 for placing lenses and a feeding manipulator 20 for taking the lenses 100 in the troughs 80 to the positioning mechanism 30 for positioning. A retrieving manipulator 40 for taking the positioned lens 100 to the grinding mechanism is arranged between the positioning mechanisms 30 of the group, and each group of the grinding mechanism includes a lens clamping mechanism and a grinding wheel driving mechanism. The tightening mechanism includes a lens rotation shaft 50 and a lens clamping shaft 60, and the grinding wheel driving mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com