Sensorless motor driving device and its driving method

A motor drive and sensor technology, which is applied in the deceleration device of DC motor, starting device, AC motor control and other directions, can solve the problems of difficulty, difficulty in shortening time, and difficulty in starting sensorless motors quickly and reliably, and achieves rapid and reliable starting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

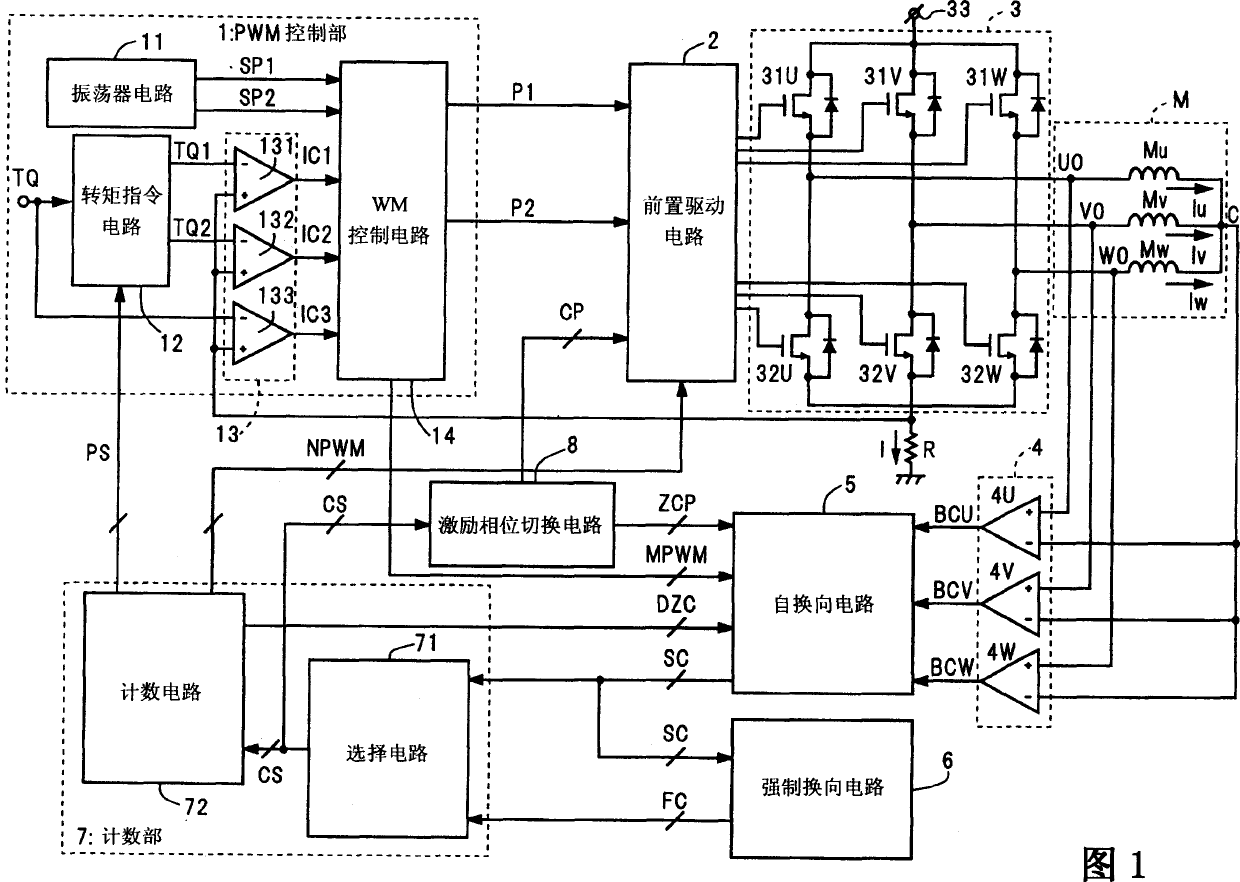

[0142] Fig. 1 shows a block diagram of a sensorless motor driving apparatus according to Embodiment 1 of the present invention. This sensorless motor driving device can be used to drive a sensorless motor M of three phases (U, V and W phases). The sensorless motor M is, for example, composed of three Y-connected motor coils Mu, Mv and Mw, three drive terminals UO, VO and WO, and one center tap C of the motor coils. The sensorless motor driving device according to Embodiment 1 of the present invention includes a PWM control unit 1, a pre-drive circuit 2, an output circuit 3, a BEMF comparison unit 4, a self-commutation circuit 5, a forced commutation circuit 6, a counting unit 7, and An excitation phase switching circuit 8 .

[0143] The output circuit 3 connects three sets of two power transistors connected in series in parallel between a power supply terminal 33 and a ground terminal that maintain a constant high voltage. The six power transistors are preferably MOSFETs, or...

Embodiment 2

[0217] The sensorless motor driving device according to Embodiment 2 of the present invention can be used to drive a sensorless motor having three phases (U, V, and W phases) in a manner similar to the driving device of Embodiment 1 described above. Except for the counting circuit 72, the components of this sensorless motor driving device are similar to those of the driving device of the above-mentioned Embodiment 1 in FIG. 1 . For similar components, reference is made to the above description of the first embodiment and to the drawings.

[0218] The internal counting circuit 72 of the sensorless driving device according to Embodiment 2 of the present invention has a different structure from that of the driving device of Embodiment 1 above. FIG. 19 is a block diagram showing the internal structure of the counting circuit 72 in the sensorless motor drive device according to Embodiment 2 of the present invention. FIG. 20 shows a timing diagram of the commutation signal CS, the ...

Embodiment 3

[0225] The sensorless motor driving apparatus according to Embodiment 3 of the present invention can be used to drive a sensorless motor having three phases (U, V, and W phases) in a manner similar to the driving apparatus of Embodiment 1 described above. Except for the forced commutation circuit 6, the components of this sensorless motor driving device are similar to those of the driving device of the above-mentioned embodiment 1 in FIG. 1 . For similar components, reference is made to the above description of the first embodiment and to the drawings.

[0226] According to the sensorless driving device of Embodiment 3 of the present invention, its internal forced commutation circuit 6 has a different structure from that of the driving device of Embodiment 1 above. Fig. 21 is a block diagram showing the internal structure of the forced commutation circuit 6 in the sensorless motor driving device according to the third embodiment of the present invention. In FIG. 21 , componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com