Lathe processing eccentric deep hole clamp

A lathe processing and eccentric technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of difficult to guarantee workpiece positioning accuracy, workpiece surface damage, low work efficiency, etc., to improve the processing qualification rate, reduce Effects of labor volume, improved machining efficiency, and manufacturing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

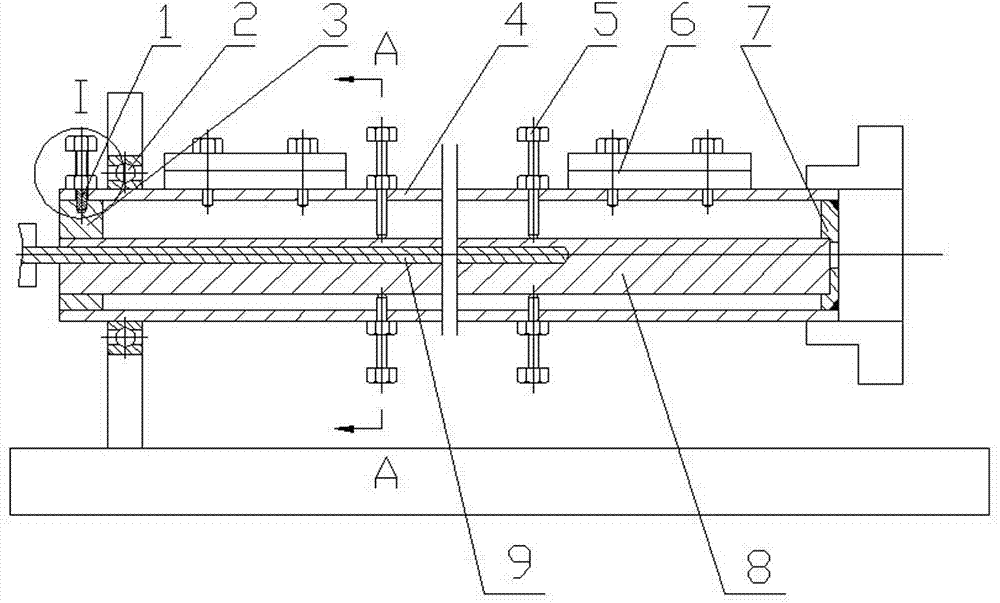

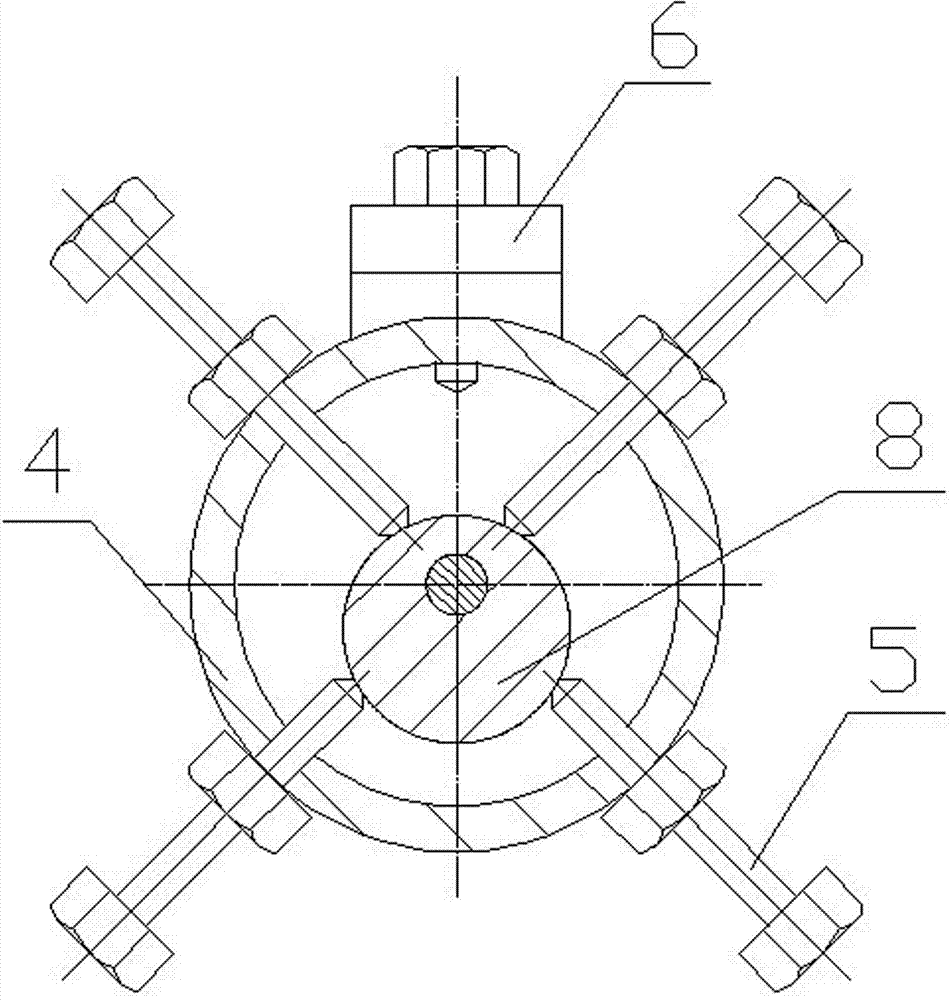

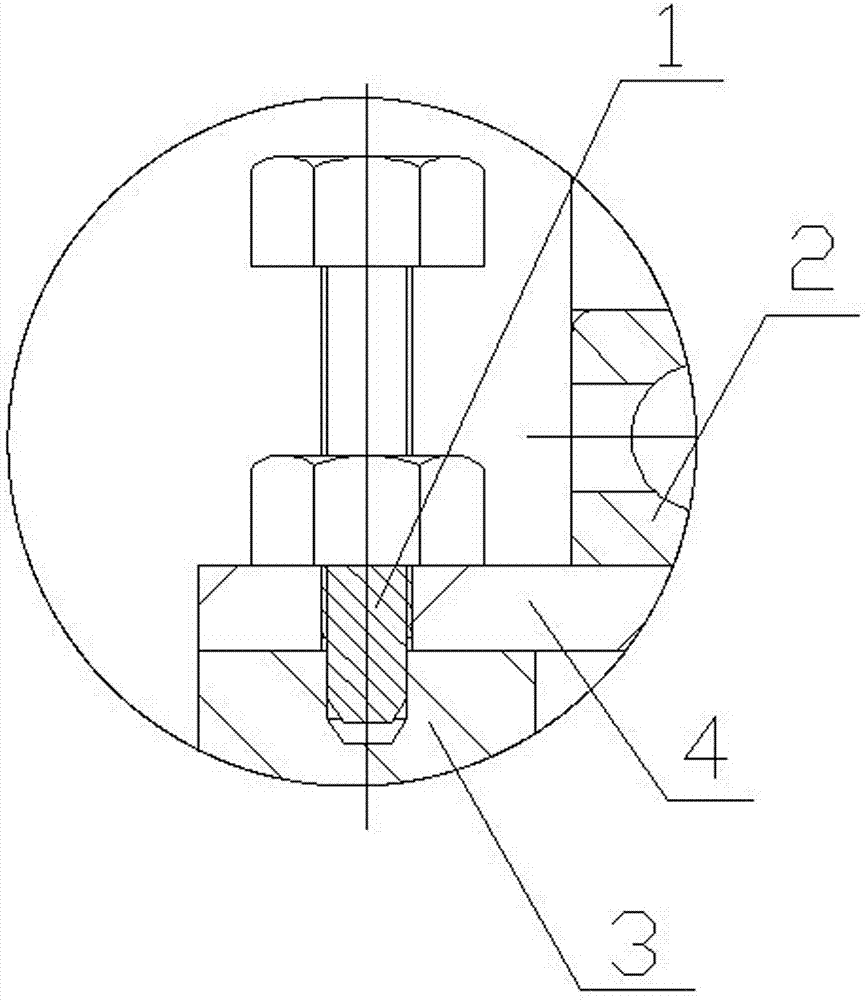

[0020] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] Such as Figure 1 to Figure 3 As shown, the lathe processing eccentric deep hole fixture of the present invention comprises a clamping sleeve 4, the center line of the clamping sleeve 4 is coaxial with the center line of the lathe spindle, and the front and rear ends of the clamping sleeve 4 are respectively arranged There are a front eccentric flange 3 and a rear eccentric flange 7, the front eccentric flange 3 is provided with a mounting hole Ⅰ, and the rear eccentric flange 7 is provided with a mounting hole Ⅱ, and the center lines of the mounting hole Ⅰ and the mounting hole Ⅱ are coaxial and parallel Coaxial with the center line of the workpiece 8 to be processed, a counterweight 6 is provided outside the clamping sleeve 4 .

[0022] By setting the clamping sleeve, and setting eccentric flanges at the front and rear ends of the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com