Automobile steering knuckle rod part thread machining clamp and device

An automobile steering knuckle and thread processing technology, which is applied in the field of fixtures and fixtures, can solve problems such as difficulties, complex shapes, and difficult product quality control, and achieve the effects of easy loading and unloading of workpieces, ensuring plastic deformation space, and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

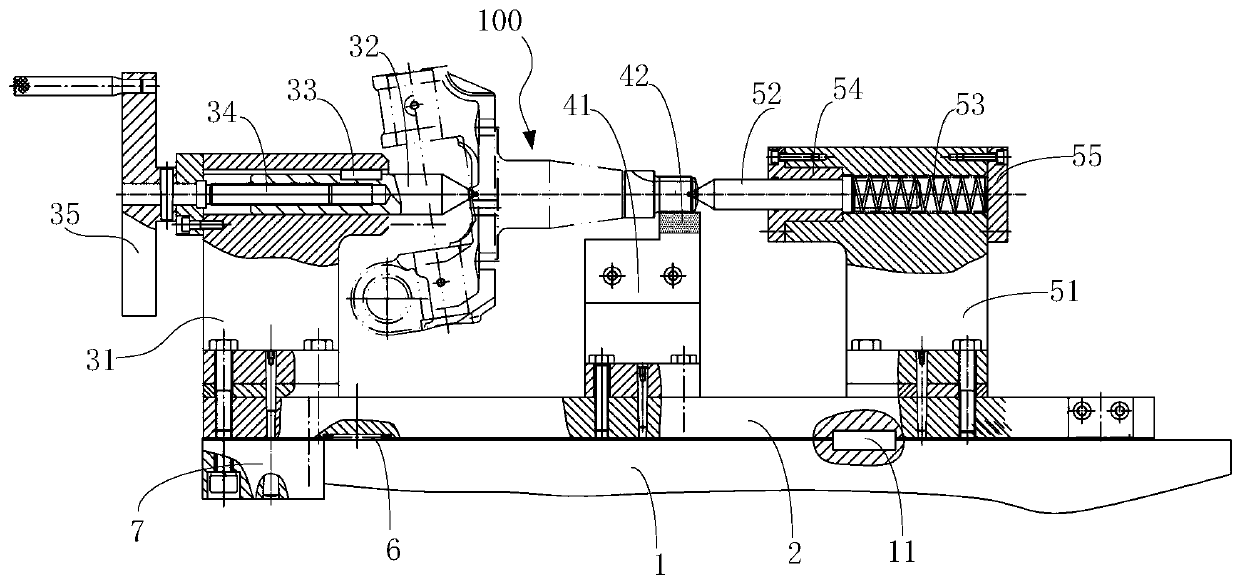

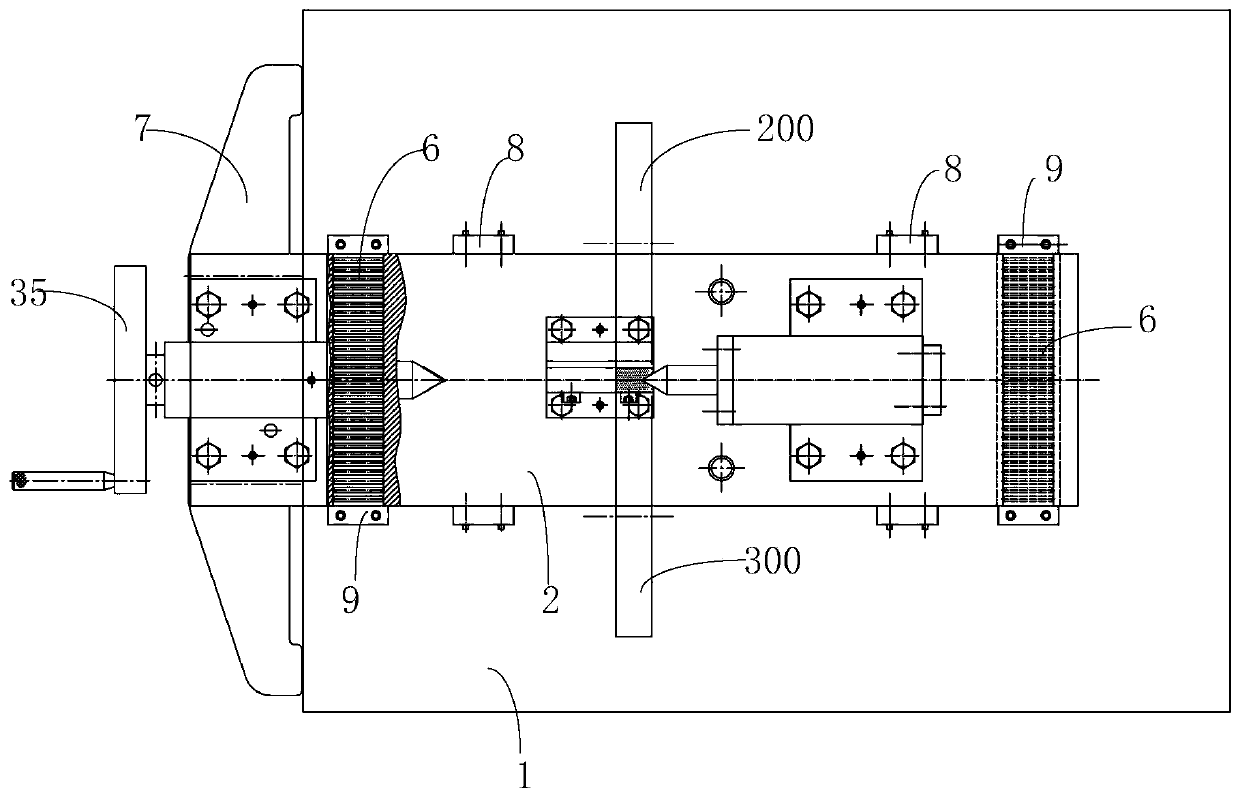

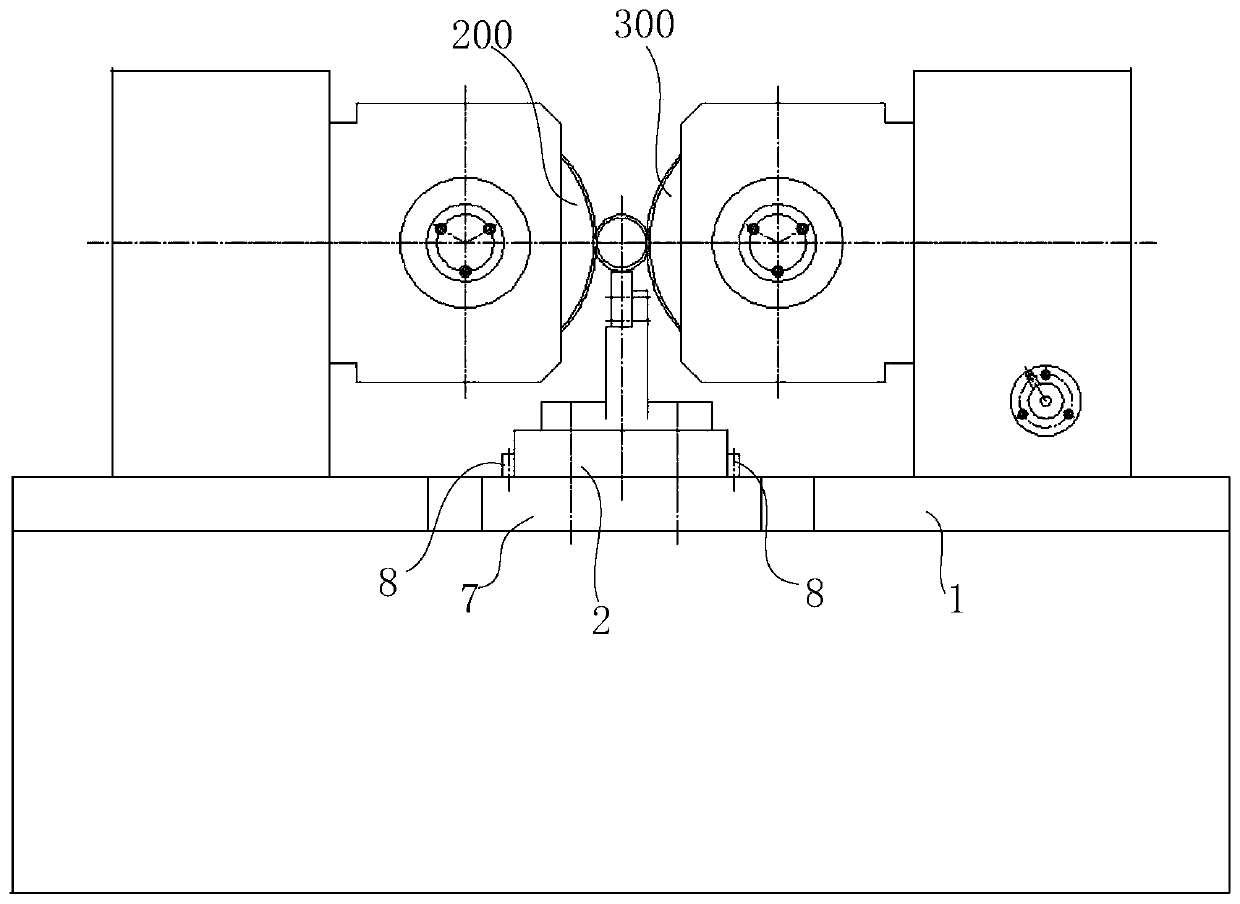

[0026] Such as Figure 1 to Figure 5 As shown, the present embodiment provides a jig for machining a screw thread of an automobile steering knuckle rod, which includes a support table 1 and a base 2 movably mounted on the support table 1, wherein the support table 1 may also be a work table; on the base 2 Two thimble mechanisms are set up front and rear, and the two thimble mechanisms are used to tighten the front and rear center holes of the steering knuckle 100 rod part, and position the workpiece during the thread rolling processing of the steering knuckle 100 rod part; one of the thimble mechanism The thimble can float along the axial direction of the rod part of the steering knuckle 100. If it is fixed, the workpiece is relatively heavy when the workpiece is installed and removed, which is difficult to install and remove, and the labor intensity of the operator is high, and it is easy to fall and damage the processing surface of the workpiece.

[0027] Wherein, the base 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com