Full-electricity servo type dispersing multi-power large horizontal opposite roller spinning equipment

An electric servo and multi-power technology, which is applied in the field of large-scale horizontal counter-wheel spinning equipment, can solve the problems of limiting the length of the workpiece, increasing the cost of equipment and molds, and unrealistic problems, and achieves the requirements of reducing power requirements, stable equipment operation, and easy maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

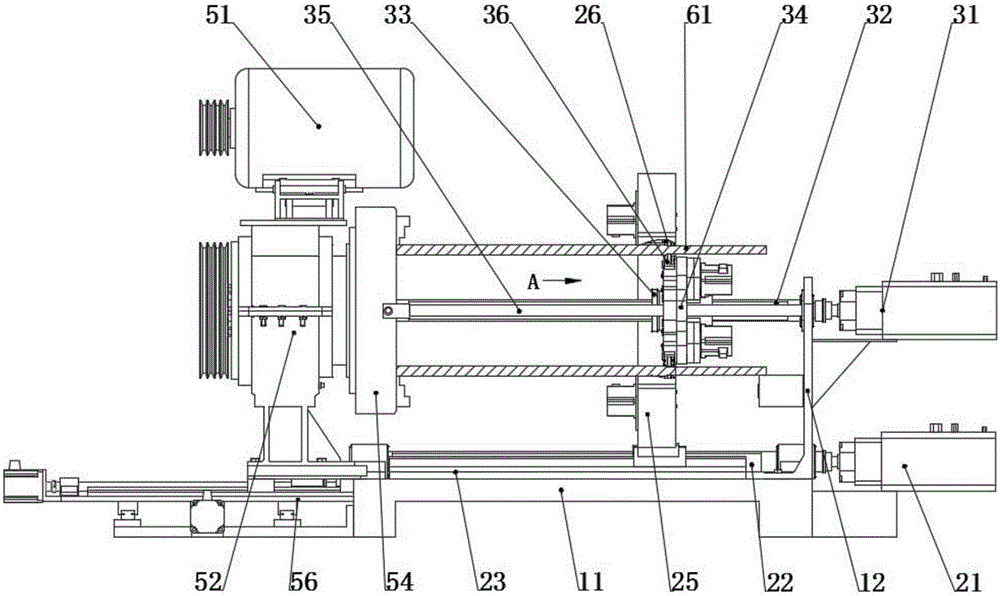

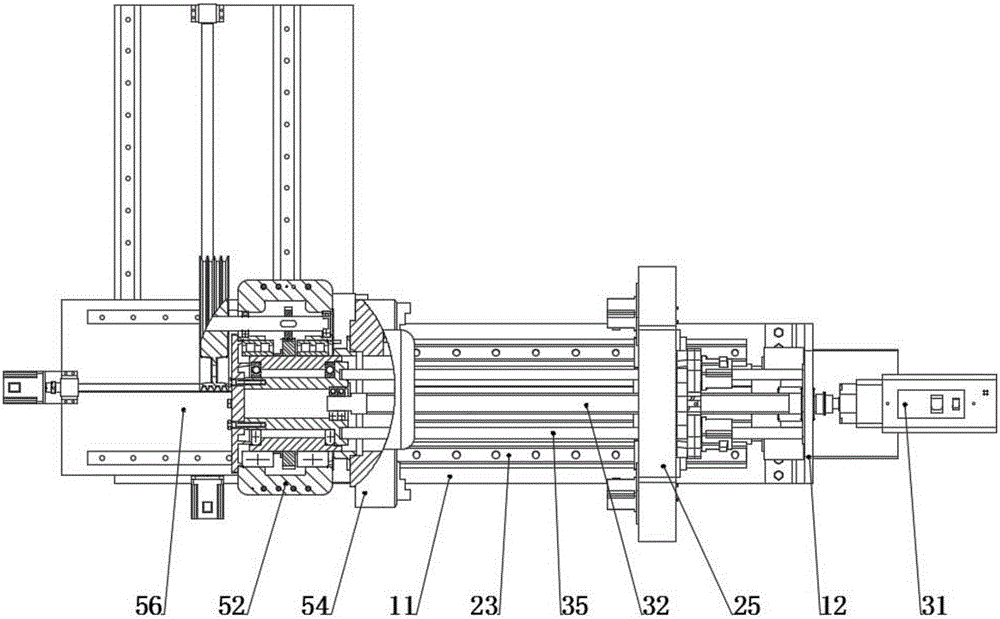

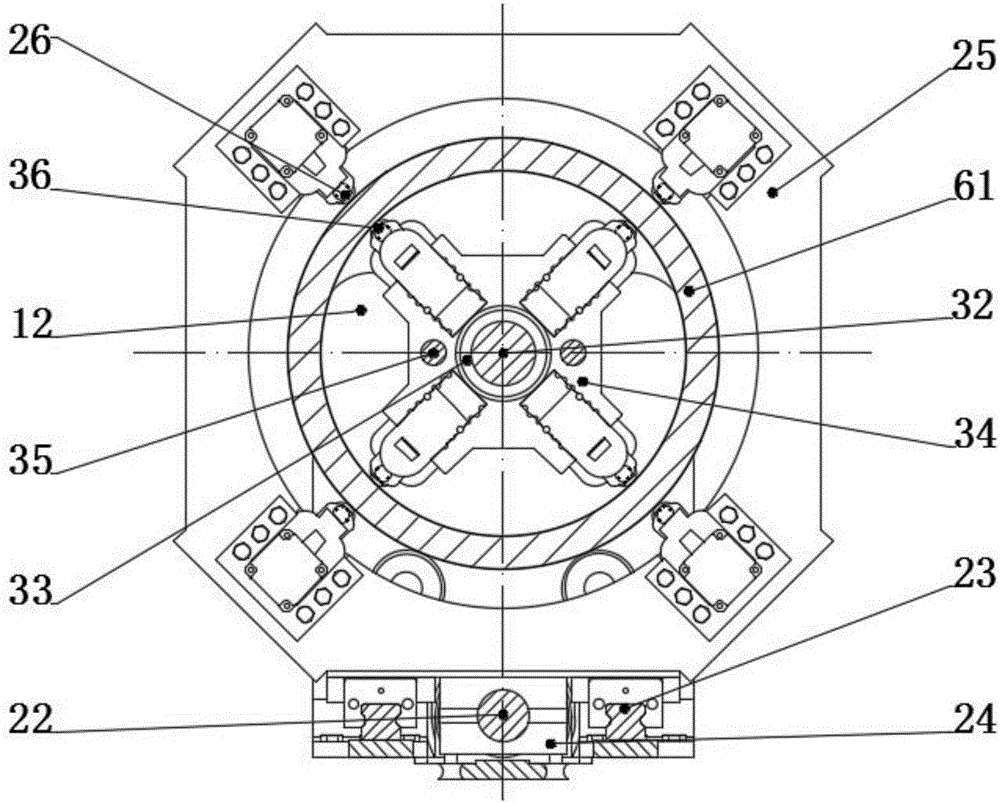

[0022] refer to figure 1 and figure 2 , an all-electric servo-type distributed multi-power large-scale horizontal wheel spinning equipment, including a base 11, a horizontal ball linear guide 23 is arranged on the base 11, and an outer wheel mechanism connected to the horizontal ball linear guide 23 The outer wheel 26 and the inner wheel 36 of the inner wheel mechanism cooperate to clamp the tube blank 61, one end of the tube blank 61 is placed on the support plate 12, the support plate 12 is connected to the base 11, and the other end of the tube blank 61 is clamped on the On the self-centering chuck 54 of the movable rotary unit.

[0023] refer to figure 1 ,and image 3 , the outer wheel mechanism includes a first servo motor 21, the output end of the first servo motor 21 is connected to one end of a horizontal ball screw 22, and the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com