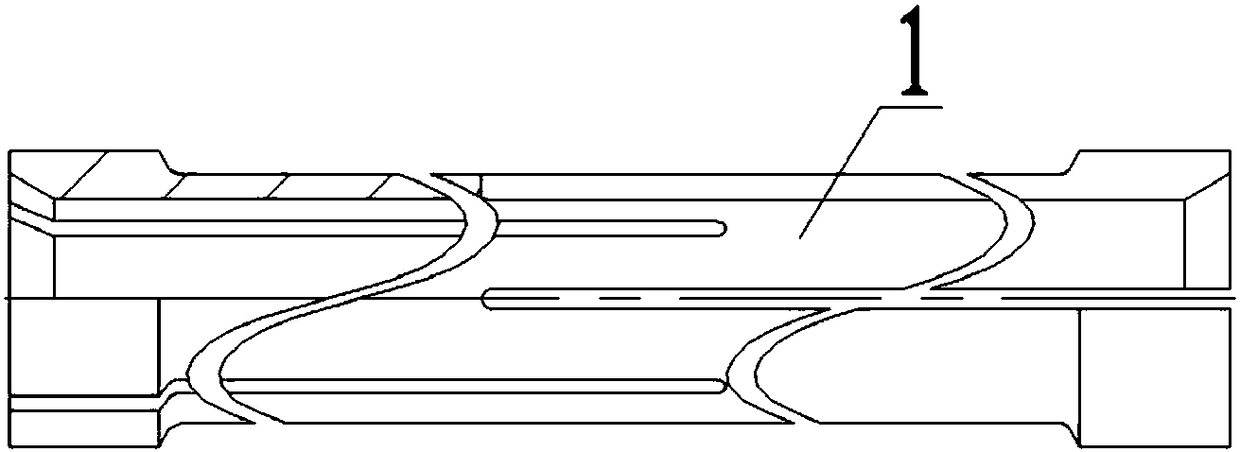

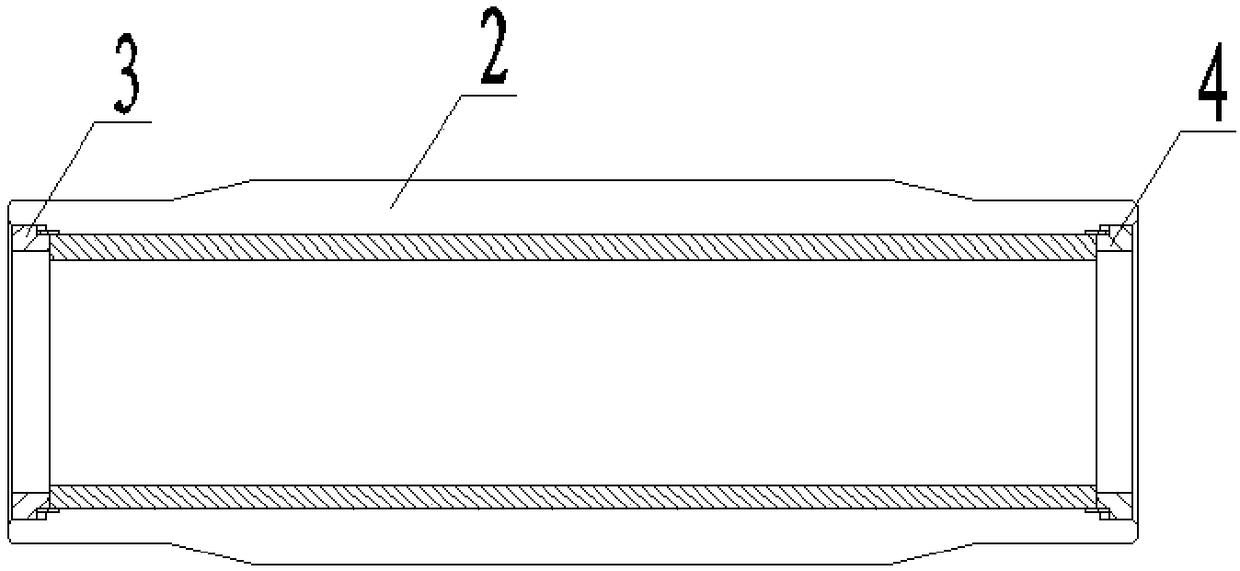

Aluminum cylinder part machining method

A processing method and aluminum cylinder technology are applied in the direction of metal processing equipment, manufacturing tools, turning equipment, etc., which can solve the problems of processing deformation of precision thin-walled aluminum cylinder parts, and achieve wide processing range, strong applicability and high positioning accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

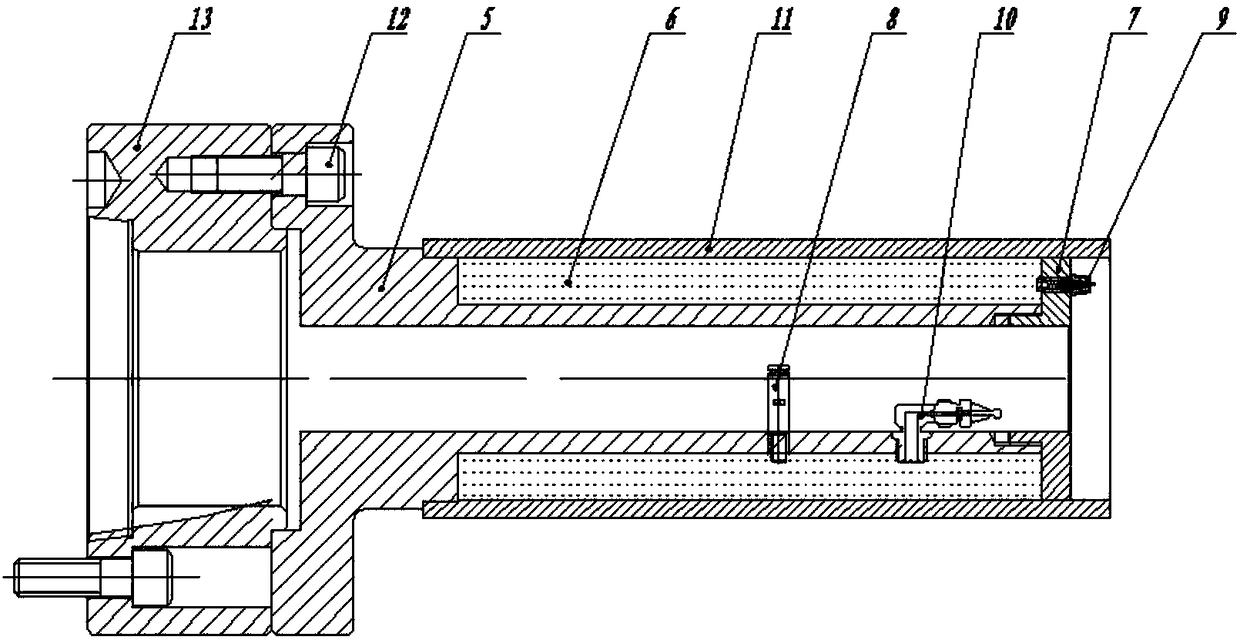

[0023] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail.

[0024] The invention provides a method for processing an aluminum cylinder, which is characterized in that it specifically includes the following steps:

[0025] S1, blanking or forming blank

[0026] This part is processed by pipe material. If the part structure is not suitable for pipe material processing, in order to avoid material waste, for parts that do not need to withstand high overload and have no special requirements for comprehensive mechanical properties, casting blanks can be used. If the part needs to withstand a certain high overload and its comprehensive mechanical properties have corresponding requirements, the use of die forging blanks can be considered under the premise of saving costs, but the corresponding technical requirements for blank production must be put forw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com