Hydraulic clamping mechanism

A hydraulic clamping and pressure technology, which is applied in the direction of expanding the mandrel, etc., can solve the problems that the geometric shape and size of the inner hole are greatly affected, defective products are reworked or scrapped, and the contact surface of the inner hole is uneven, etc., to achieve production assistance Short time, product quality assurance, fast and convenient loading and unloading of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

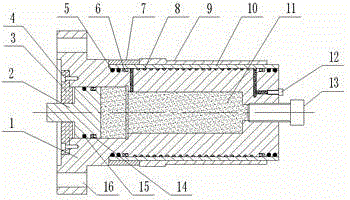

[0012] figure 1 The shown hydraulic clamping mechanism includes a base body 1, a piston 2 at one end of the middle hole of the base body 1, the piston 2 can move axially in the middle hole of the base body 1, and the other end is blocked by a second screw 13; The outside is provided with thread groove 8, elastic sleeve 10 and fixing hole 17. The thread groove 8 and the elastic sleeve 10 are closely matched. The screw 12 is blocked, and the middle hole and the thread groove 8 of the whole base body 1 are filled with pressure transmission medium to form a closed oil circuit. The elastic sleeve 10 is provided with a positioning sleeve 7 and a workpiece 9 .

[0013] The pressure transmission medium 11 is hydraulic oil, or other synthetic fluids that can transmit pressure.

[0014] In the middle hole of the base body 1 where the piston 2 is fixed by the baffle plate 3, a third sealing ring 15 and a fourth sealing ring 14 are arranged between the middle hole of the base body 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com