Elastic drying roll

A technology of squeezing dry rolls and elastic rolls, which is applied in the field of devices for squeezing out moisture on the surface of steel strips, can solve the problems of not very close contact, short service life, and impact on product quality, so as to reduce maintenance costs, improve product quality, and structure simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

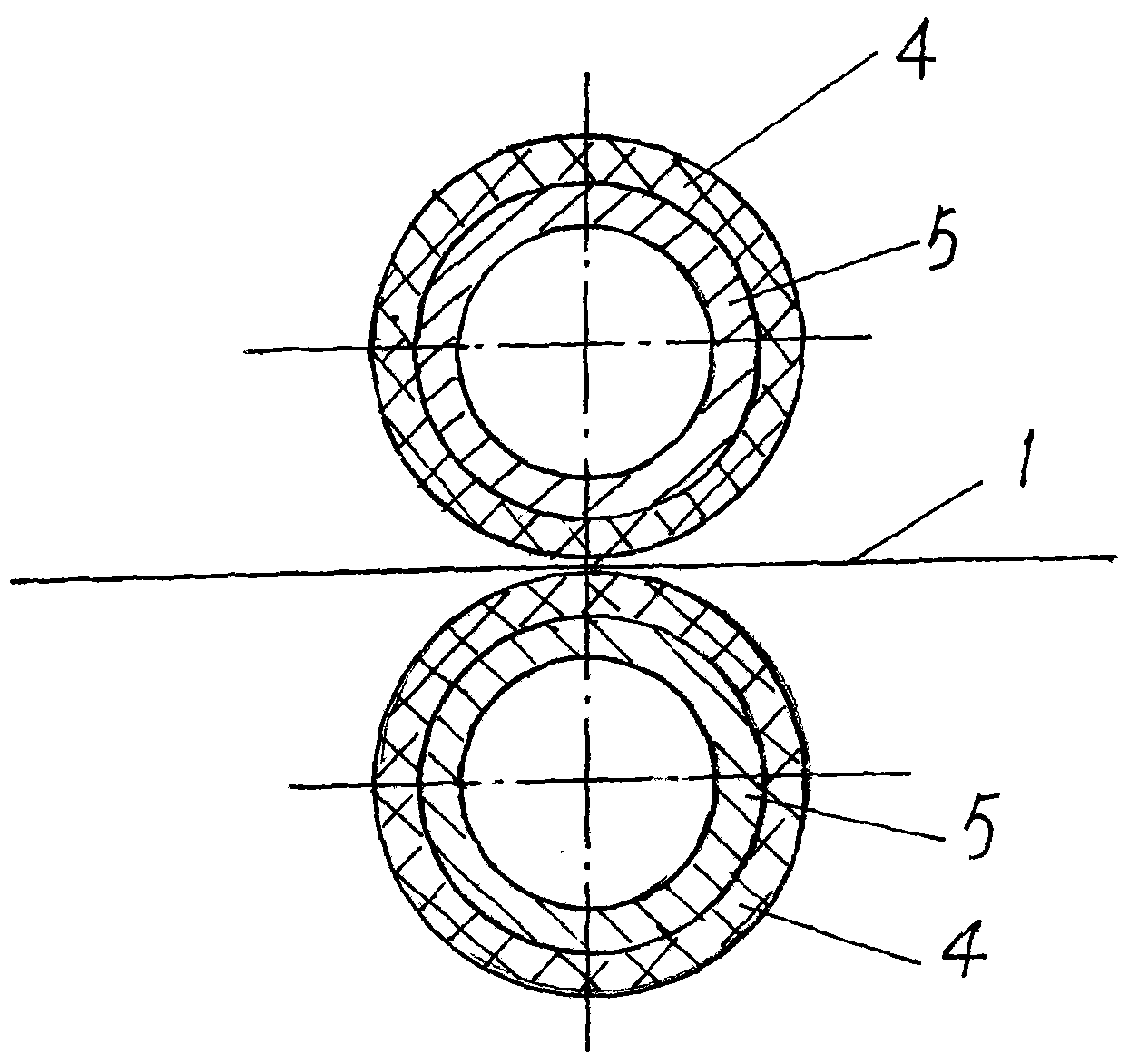

[0011] Please see attached figure 1 , the known rigid roll core (5) of the squeeze roll is made of rigid material, and only the roller sleeve (4) on the surface has a certain elasticity, so the squeeze roll and the steel strip (1) are not in contact with each other during use. It is very tight, so it has a great impact on product quality. Simultaneously, once the axle sleeve (4) is used several times and ground and cut thin, the contact between the squeeze roller and the steel strip is very poor, and the squeeze roller has to be scrapped, and the service life is also shorter.

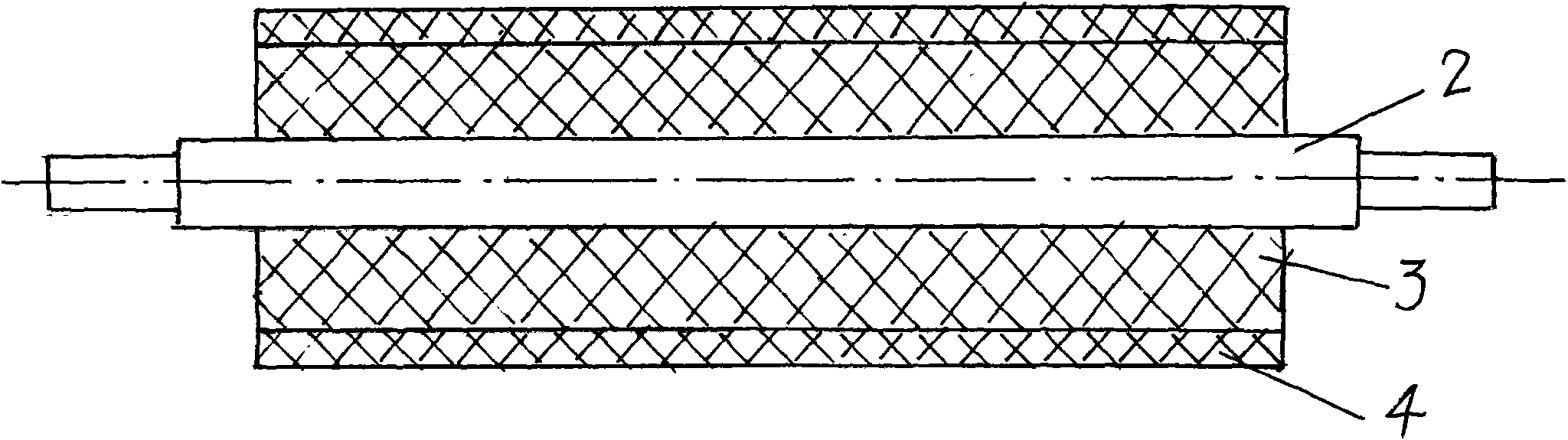

[0012] exist figure 2 In a specific embodiment of the invention shown: the roller shaft (2) is a long shaft.

[0013] In another specific embodiment of the present invention, elastic material is wrapped on the roller shaft (2) to make the elastic roller core (3), which can be deformed under the action of external force.

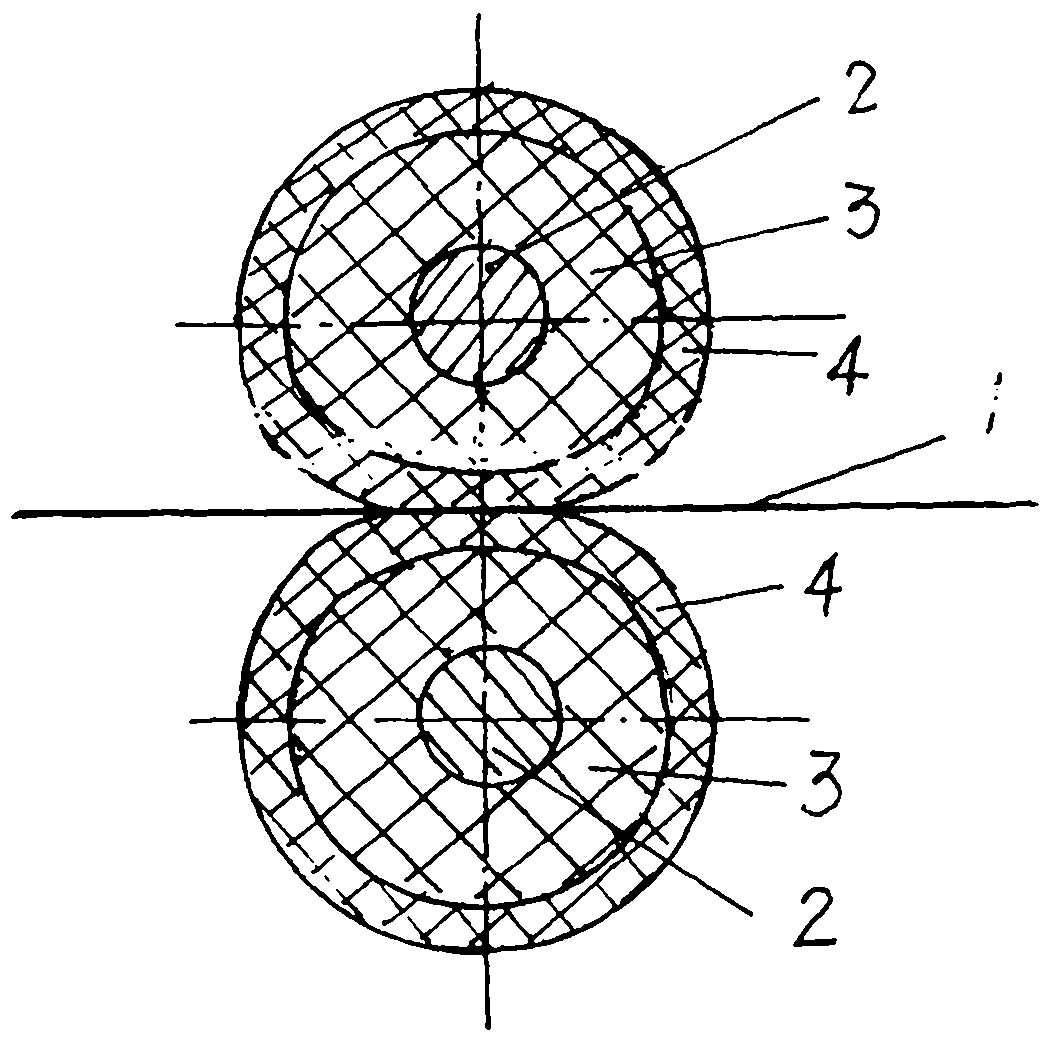

[0014] please see image 3 , an embodiment of the present invention is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com