Motor car engine rocker processing chucking appliance

A technology of automobile engines and jigs, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., and can solve problems affecting the accuracy of blank loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

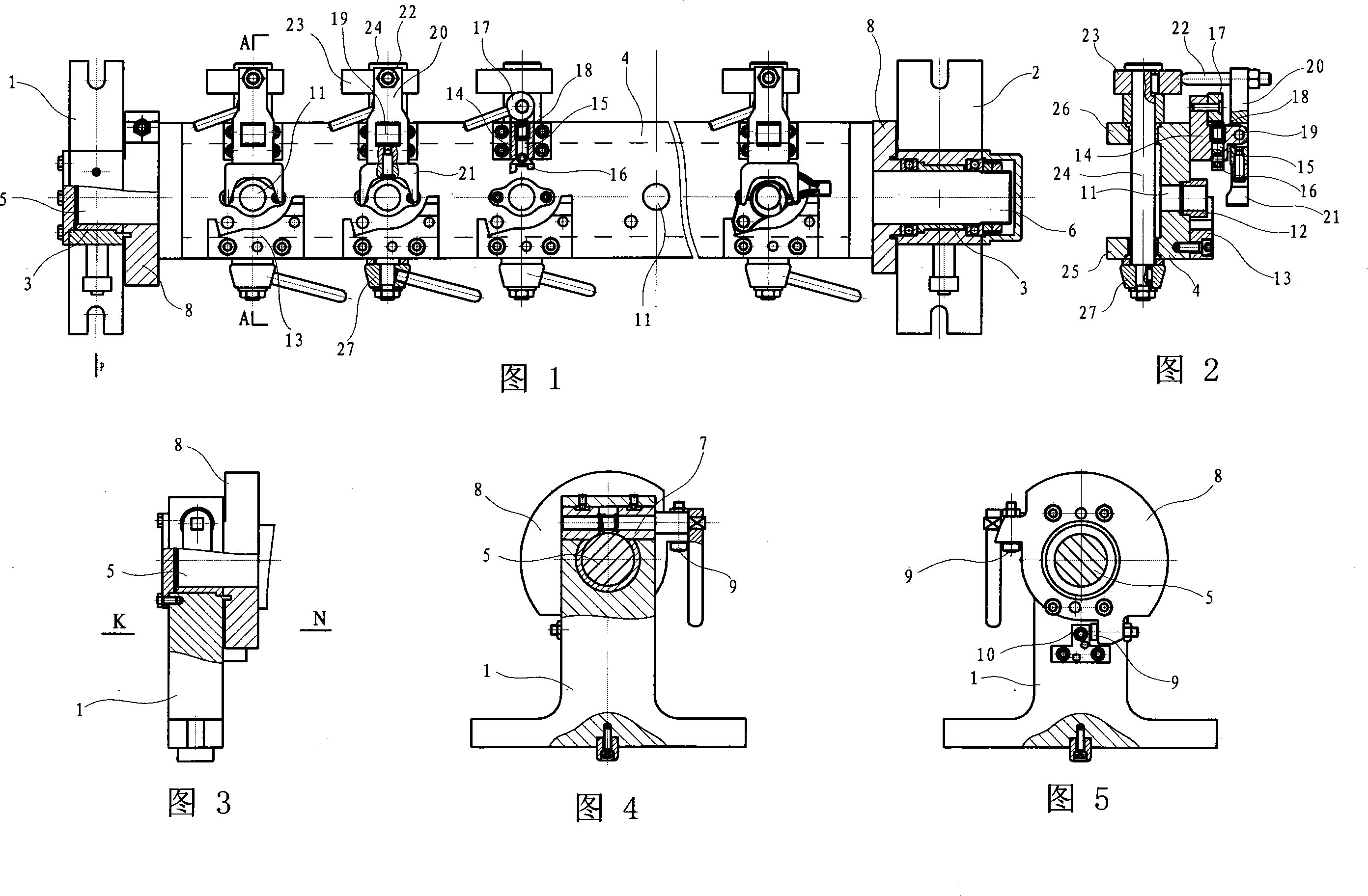

[0015] In Fig. 1, Fig. 2, Fig. 3, Fig. 4, and Fig. 5, the automobile engine rocker arm processing card has left and right support seats 1, 2, and there are respectively support seat axle seats 3 on the left and right support seats, and the left and right supports Rectangular slot-shaped card body 4 is arranged between the seats, and the left and right ends of the card body along the length direction respectively have the card body shaft 5,6 in the left and right support seat shaft seats, and the top in the support seat shaft seat has the card body The clamping brake 7 of the shaft has a turntable 8 at the left and right ends of the rectangular groove of the card body, and there are corresponding ninety-degree rotation limit stops 9 and 10 between the turntable and the support seat. The bottom is evenly distributed with eight chip removal holes 11 matched with the shaft hole of the rocker arm along the left and right directions. The front support platform 13 matched with the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com