Shoe upper and shoe tree vertical circulation two-in-one dryer

A two-in-one, dryer technology, applied in shoe-making machinery, footwear, clothing and other directions, can solve the problems of large floor space, low thermal efficiency, environmental pollution, etc., to improve the utilization rate of heat energy and reduce labor intensity , the effect of improving the automation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

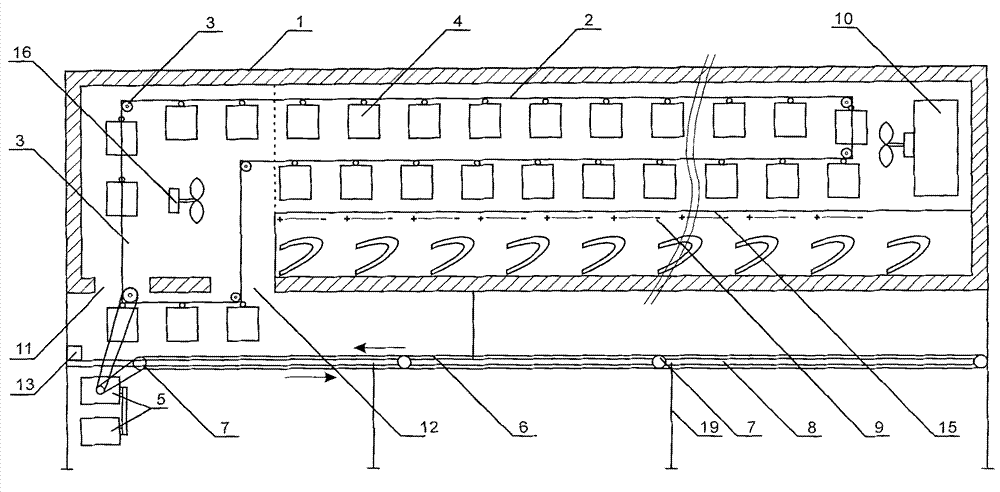

[0013] figure 1 Among them, the shared oven (1) is fixed on the frame (19), and the conveyor chain (2) enters the shared oven (1) from the oven inlet (12) through the transmission wheel (3) to run toward one end and turn back 360 degrees upwards from the oven outlet (11) come out to form a circulation loop, the shoe last hanger (4) is suspended on the conveyor chain (2), a set of transmission wheels (3) is connected with the speed reducer (5), and an air source is provided at one end of the shared oven (1) The heat pump (10) is provided with a convection fan (16) at the other end of the shared oven (1), and the electric control cabinet (13) is located at the inlet and outlet (11) (12) of the shared oven (1).

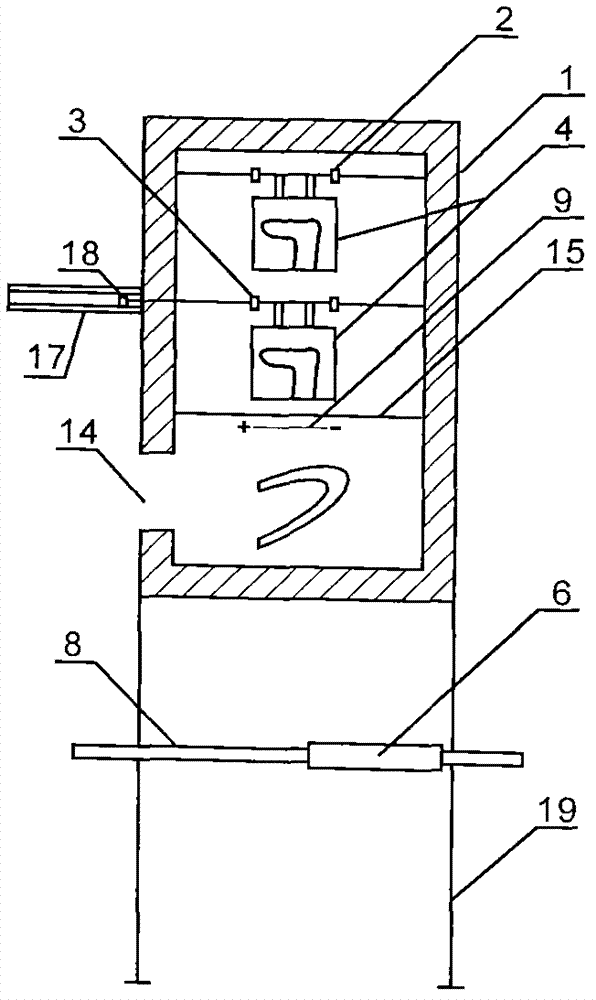

[0014] figure 2 Among them, an isolation plate (15) is set in the shared oven (1), an emergency electric heating system (9) is arranged above the isolation plate (15), and an electric heating system (9) and a shoe upper delivery port (14) are arranged below.

[0015] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com