A marine bottleneck tower derrick and its manufacturing method

A tower-shaped derrick and bottleneck-type technology, applied in the field of offshore drilling rigs, can solve the problems of derrick fineness and production scale gap, and achieve the effect of accurate size, high work efficiency and guaranteed quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

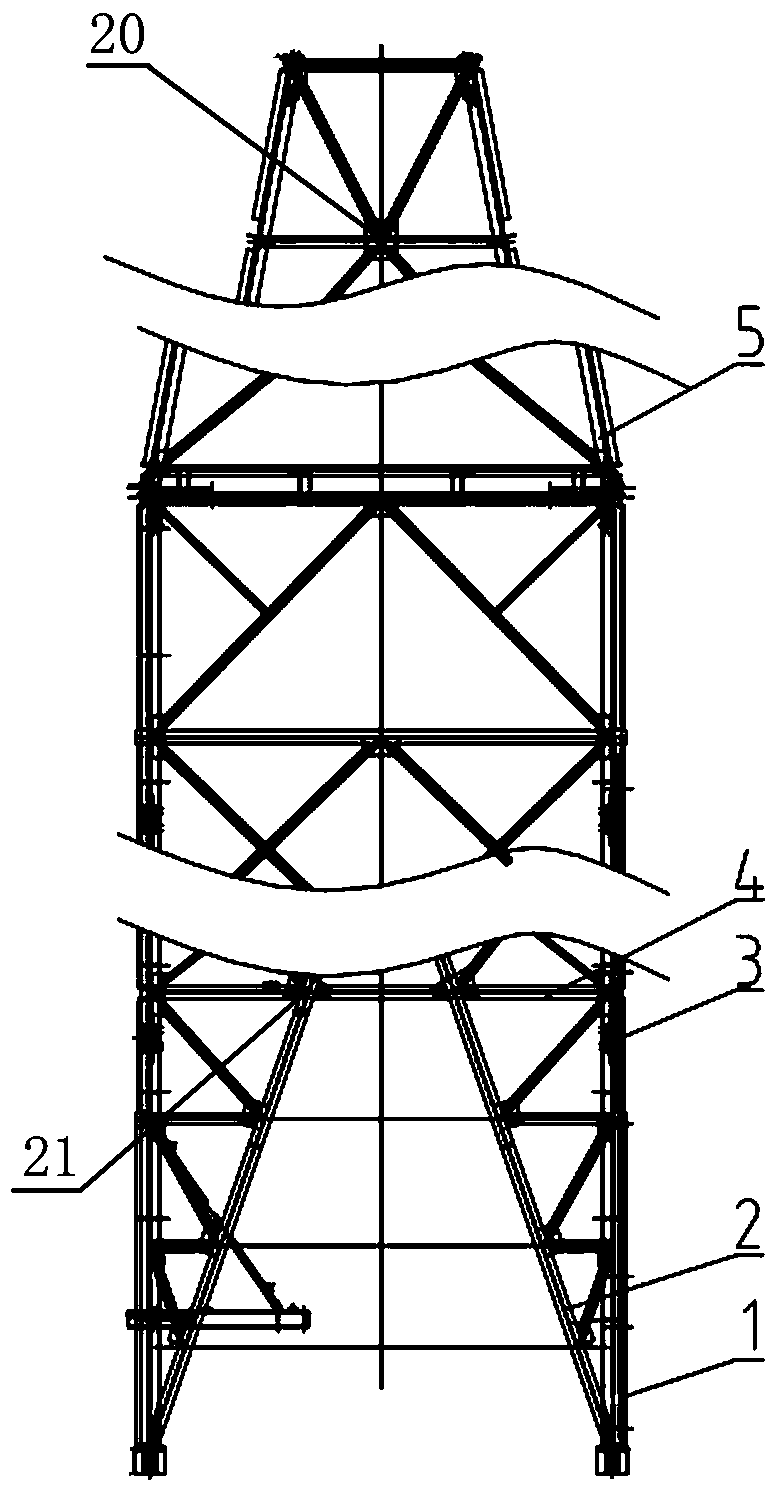

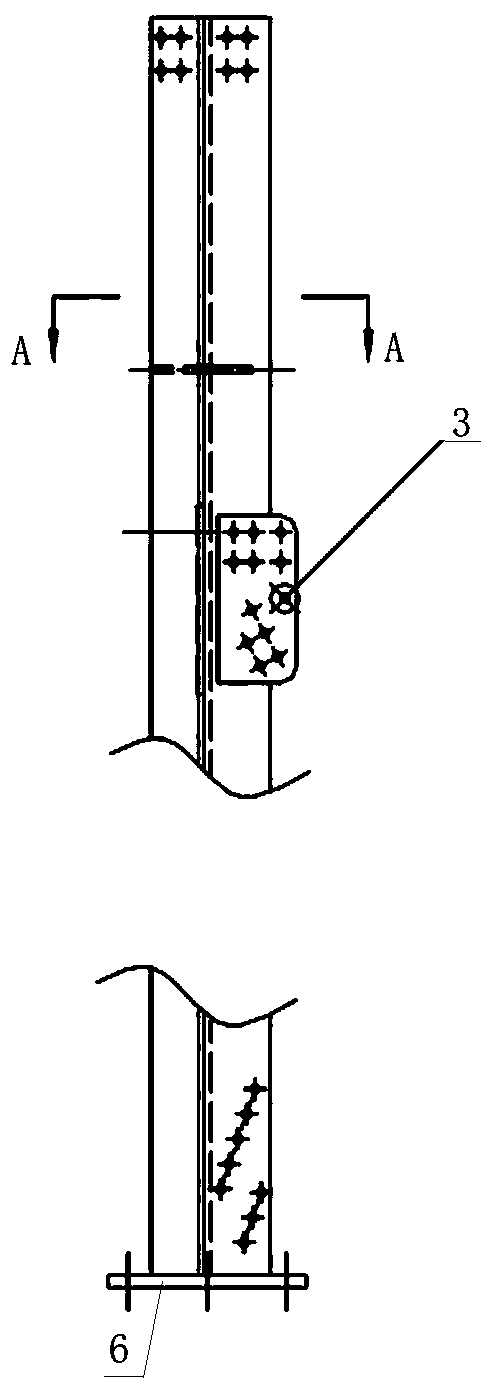

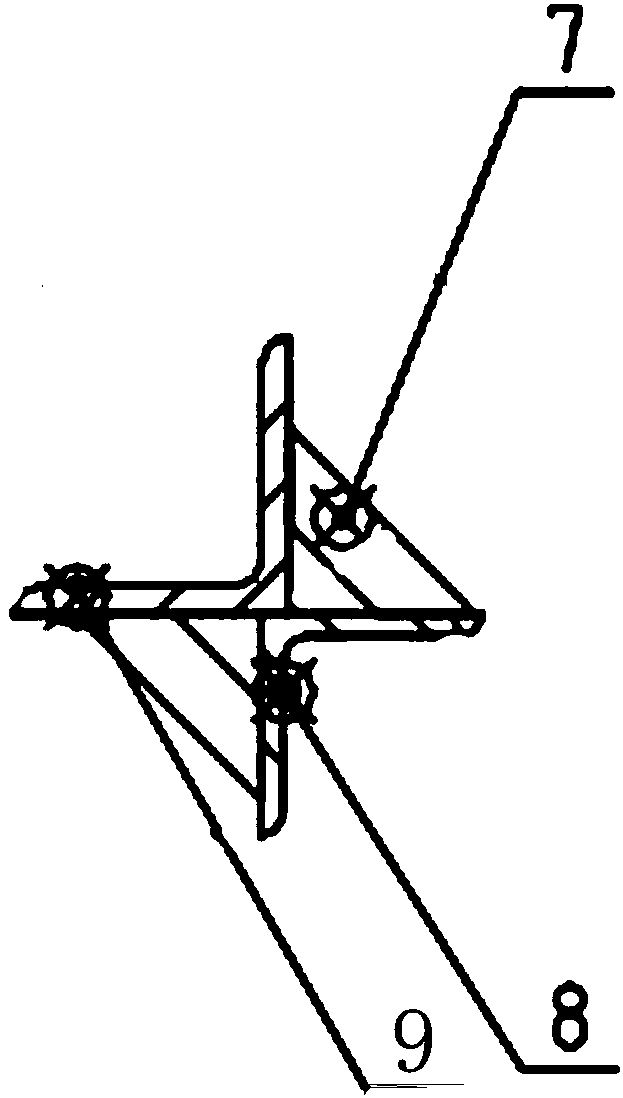

[0033] see Figure 1 to Figure 6 , a marine bottleneck tower derrick, comprising a derrick main body, the derrick main body has a straight section 21 arranged at the lower part and a close-up section 20 arranged at the upper part, and the straight section 21 and the close-up section 20 each include several diagonal braces 2 and cross braces 4, and the straight section 21 also includes a number of upright column bodies 1, the closing section 20 also includes a number of slanted column bodies 5, and the upright column bodies 1 and the slanted column bodies 5 are fixed with diagonal braces 2, the other end of the diagonal brace 2 is fixed to the cross brace 4, and the cross brace 4 is also fixed to the upright column body 1 and the oblique column body 5 respectively; the upright column body 1 and The oblique column body 5 is welded by corner brace I and corner brace II in a cross shape, and the cross welding of corner brace I and corner brace II is provided with a rib plate, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com