Method for processing bi-color mold blank

A processing method and technology of two-color mold, which is applied in the field of processing mold blanks, can solve the problems of dependence on overall precision, high price, and high processing cost of two-color mold blank products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

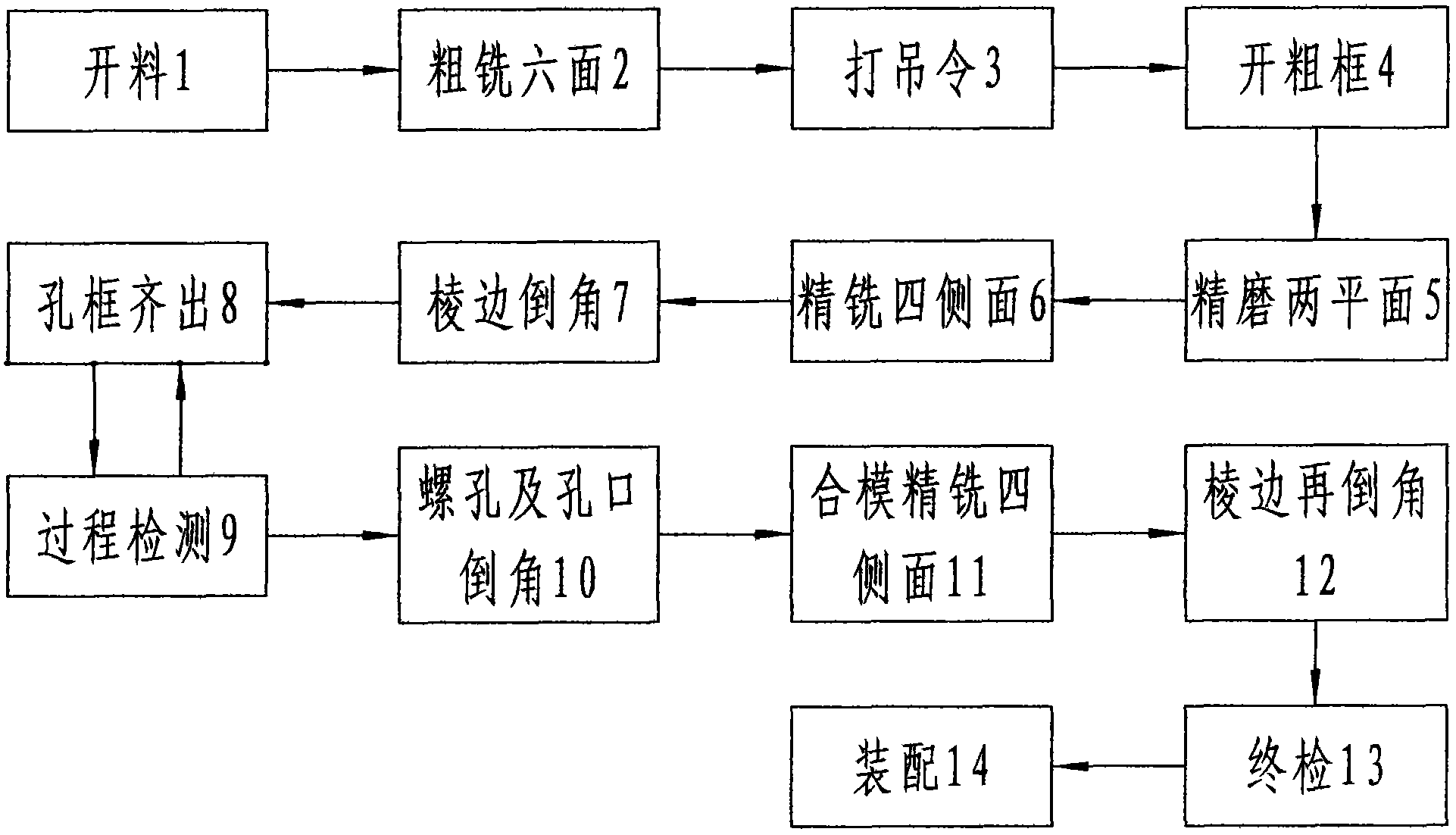

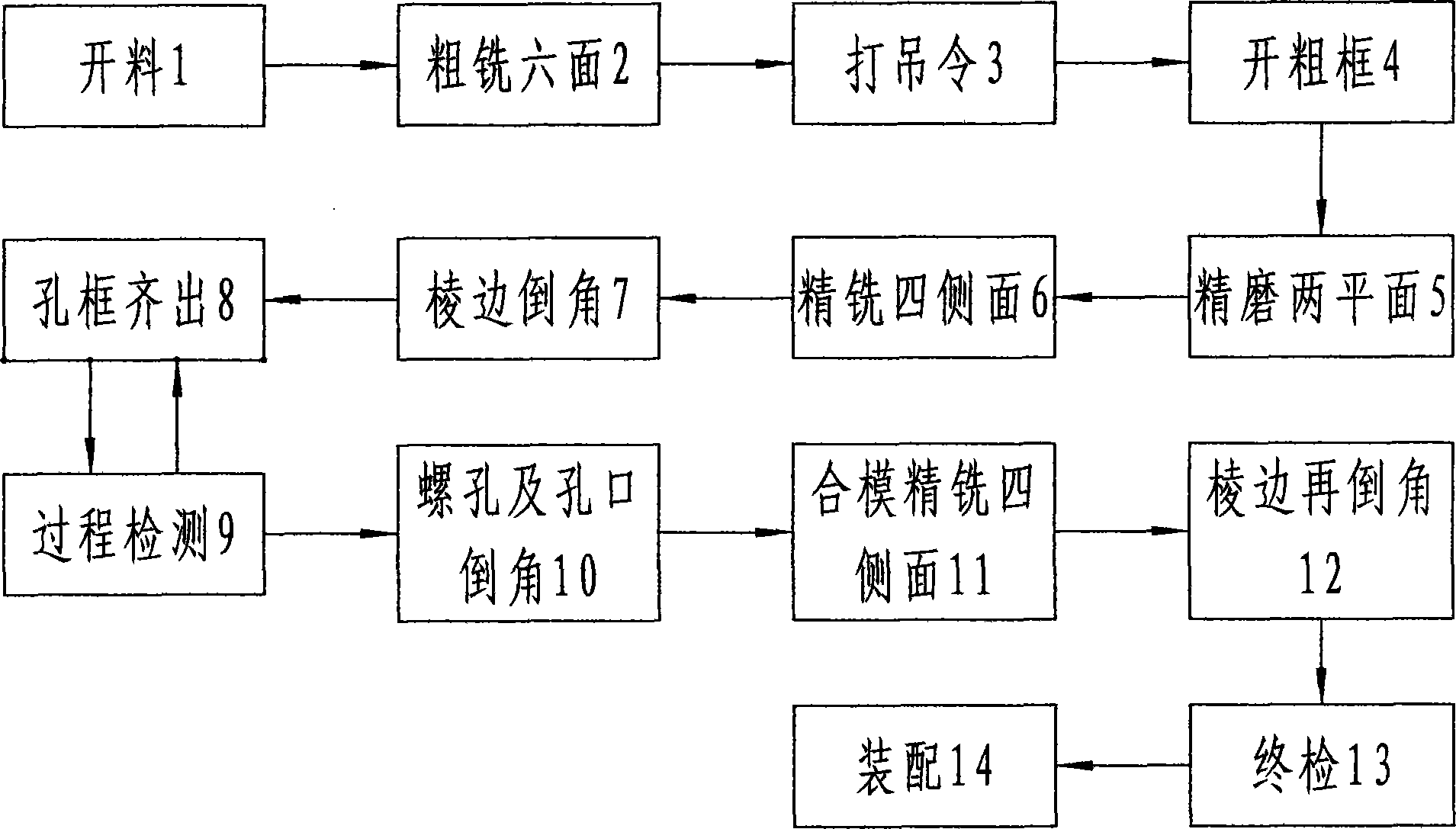

[0026] refer to figure 1 , a method for processing a two-color mold base of the present invention, the process flow of the method is as follows in turn: cutting 1, rough milling six sides 2, hanging order 3, rough frame opening 4, fine grinding two planes 5, fine milling four Side 6, edge chamfering 7, hole frame out 8, process inspection 9, screw hole and hole chamfering 10, mold closing and fine milling four sides 11, edge chamfering 12, final inspection 13, assembly 14, Wherein: the described material cutting 1 is according to the size of the drawing and the processing margin of each process is reserved, and the rectangular material steel plate used to make the two-color mold blank is cut from the raw material large steel plate with a sawing machine; the drawing is a two-color mold Detailed engineering breakdown diagram of blank products;

[0027] The rough milling of the six sides 2 is based on the size of the drawing and the machining allowance of the subsequent process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com