Conformal cooling waterway mold structure and processing method

A cooling water channel and processing method technology, applied in the field of mold manufacturing, can solve the problems that 3D printing cannot meet the printing requirements of large-size inserts, and the cost of molds with cooling water channels is high, so as to reduce processing and manufacturing costs and facilitate popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

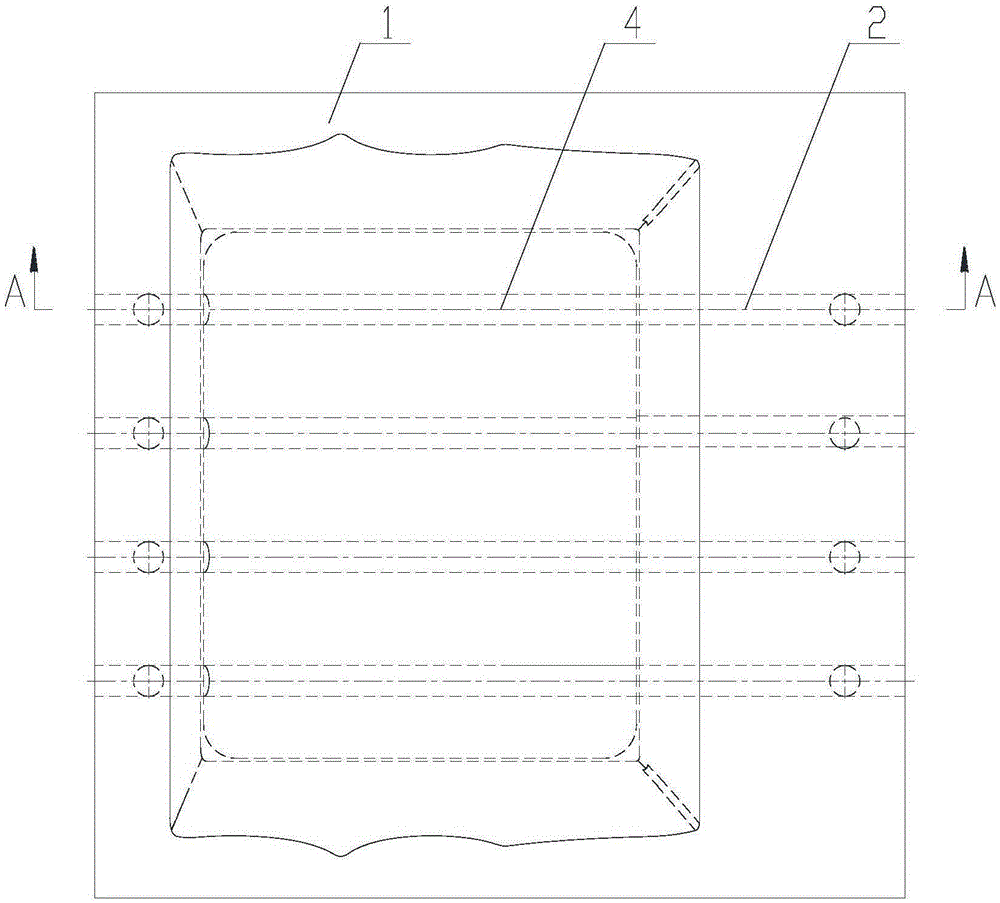

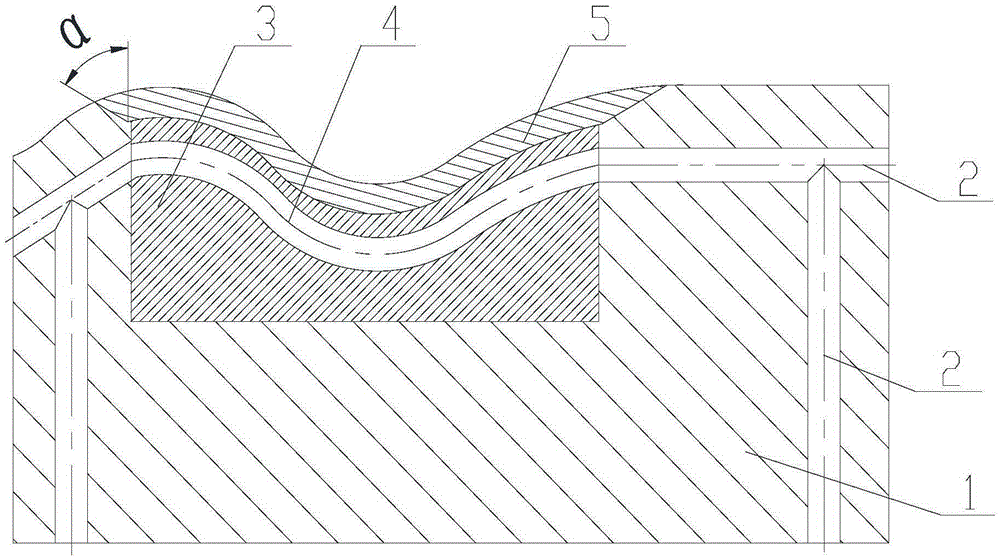

[0029] like figure 1 and figure 2 As shown, the conformal cooling water channel mold structure of the present invention includes a base body 1 and an insert 3, grooves are arranged on the molding surface of the base body 1, and at least two water channels communicating with the grooves are arranged in the base body 1, as figure 2 The shown arrangement provides a straight-through water channel 2 in the base body 1 . An insert 3 is installed in the groove of the base body 1, and a follow-up water channel 4 is arranged in the insert 3, and both ends of the follow-up water channel 4 respectively communicate with the straight-through water channel 2 provided in the base body 1 to form channels. The insert 3 is assembled by an upper insert and a lower insert, and the joint surface passes through the follow-up channel 4 , preferably the join surface passes through the center line of the follow-up channel 4 . A cladding layer 5 is provided at the joint between the insert 3 and the...

no. 2 example

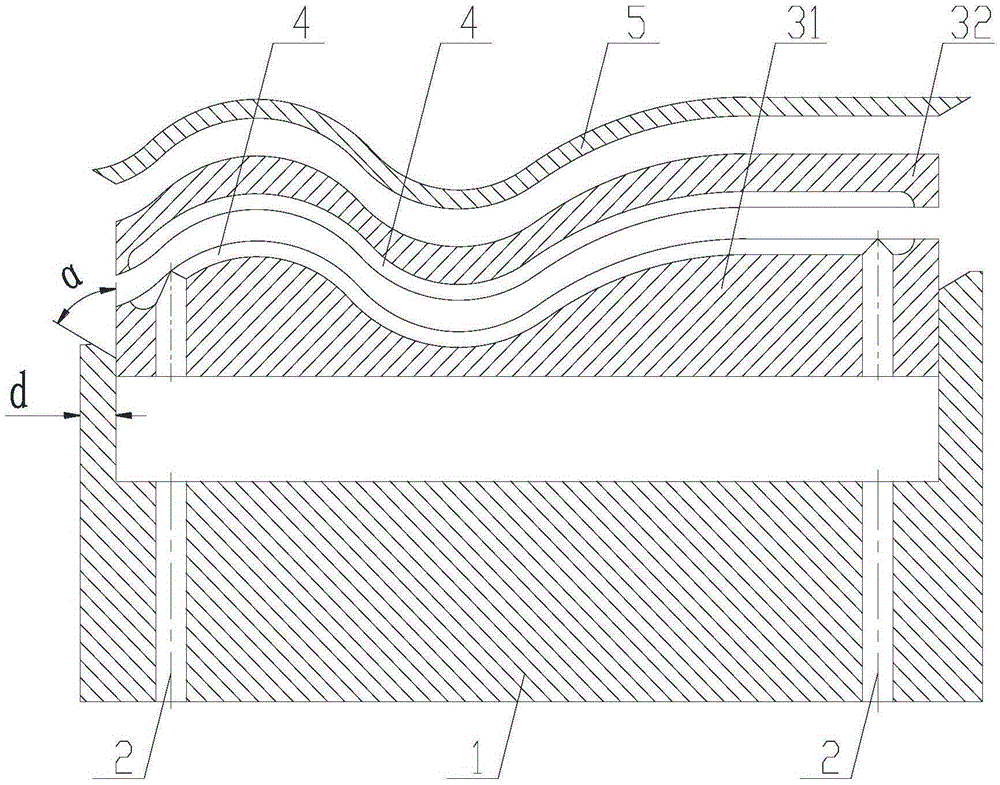

[0034] like image 3 As shown, the conformal cooling water channel mold structure of the second embodiment includes a base body 1 and an insert 3, grooves are arranged on the molding surface of the base body 1, and at least two water channels communicating with the grooves are arranged in the base body 1, as As shown in the figure, two vertical straight-through water channels 2 are set in the base body 1 . The insert 3 is installed in the groove of the base body 1, and the insert 3 is composed of a lower insert 31 and an upper insert 32, wherein the lower insert 31 is provided with a straight water channel communicating with the straight water channel 2 inside the base body 1, and the lower insert 31 The upper surface of the upper surface and the lower surface of the upper insert 32 are respectively provided with a semicircular conformal waterway 4, and the lower insert 31 and the upper insert 32 are put together to form a complete conformal waterway 4, and the conformal water...

no. 3 example

[0038] like Figure 4 As shown, the conformal cooling channel mold structure of the third embodiment includes a base body 1 and an insert 3, grooves are arranged on the molding surface of the base body 1, and the conformal cooling channel mold structure has two molding surfaces, that is, the upper part of the base body 1 A groove is provided, the right part of the substrate 1 is provided with a groove, and a semicircular conformal water channel is provided at the bottom of the groove, and inserts 3 are respectively arranged in the groove, and a semicircular conformal water channel is arranged on the insert 3, and the insert 3 After being installed in the groove, the two semicircular conformal water channels form a complete conformal water channel, and the conformal water channel communicates with the straight water channel 2 in the base body 1 . The outer surface of the insert 3 is a cladding layer 5, and the outer surface of the cladding layer 5 is a molding surface.

[0039...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com