Surface ceramic bovine stephanoporate bamboo charcoal wave-suction material of load magnetic metal and method of producing the same

A technology of magnetic metal and wave absorbing material, applied in the direction of magnetic field/electric field shielding, electrical components, etc., can solve problems such as difficulty, and achieve the effect of increasing performance, enhancing electrical conductivity, and improving the degree of graphitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

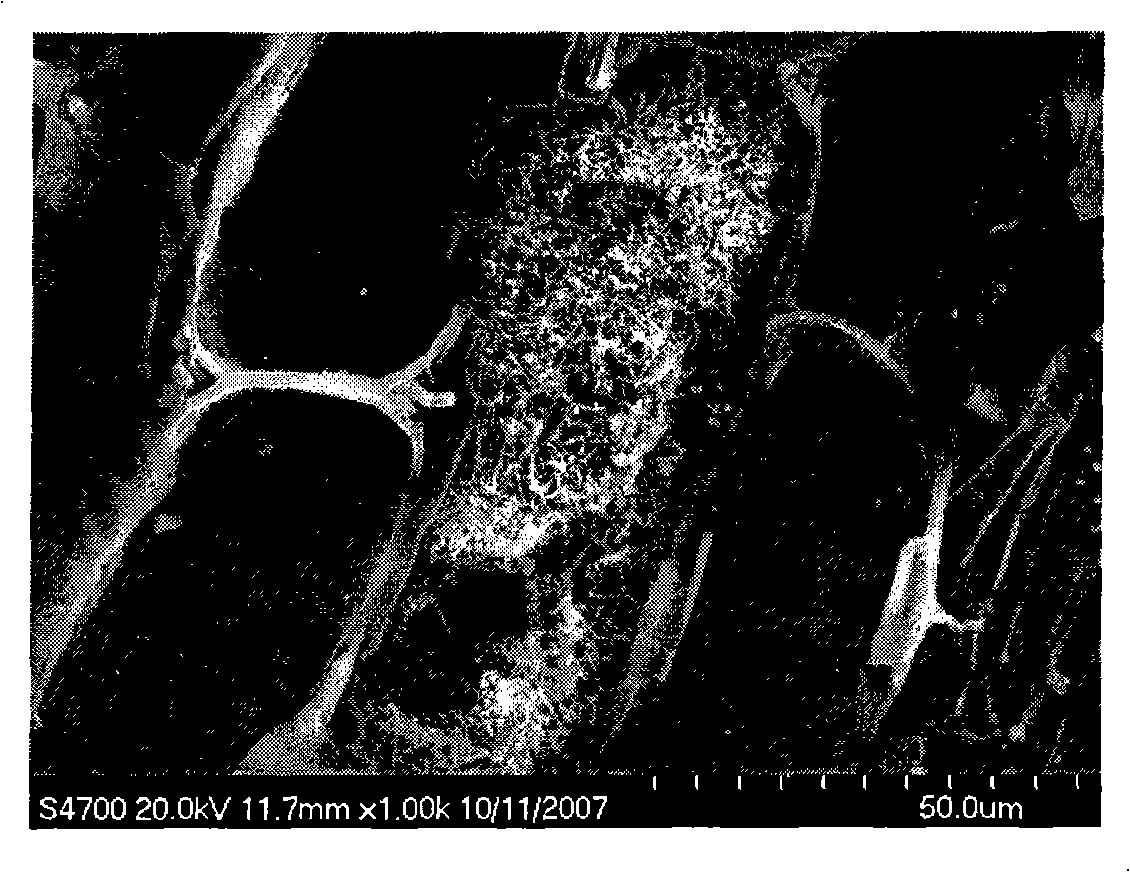

[0020] Cut bamboo slices of 20mm×8mm×3mm from the thorny bamboo, and dry the bamboo slices to remove moisture. The bamboo slices were soaked in a sodium hydroxide solution with a concentration of 3 mol / L for 10 hours, then suction filtered and rinsed with deionized water until the pH value of the filtrate was 7. Bamboo slices were dried at 120°C. Bamboo slices were placed in a carbonization furnace and carbonized at 800°C under the protection of nitrogen for 3 hours to prepare bamboo charcoal.

[0021] Bamboo charcoal was soaked in 3mol / L nickel sulfate solution for 12 hours, and then suction filtered. Bamboo charcoal was dried at 120°C.

[0022] Put the bamboo charcoal in the prepared silica sol and infiltrate it in vacuum for 10 hours, then take it out and heat it in the oven at 60°C for 4 hours to make the silica sol gelation reaction, and then continue to heat it at 120°C Tumble dry.

[0023] Finally, the bamboo charcoal was placed in a carbonization furnace and carbon...

Embodiment 2

[0027] Take by weighing 5g of bamboo charcoal powder with a particle size of 500 mesh, dry and remove moisture. The bamboo charcoal powder was soaked in a sulfuric acid solution with a concentration of 1mol / L for 18 hours, then suction filtered and rinsed with deionized water until the pH value of the filtrate was 7.

[0028] Dry the bamboo charcoal powder in an oven at 120°C. Then soak the bamboo charcoal powder in 2mol / L ferric chloride solution for 18 hours, then suction filter. Dry the bamboo charcoal powder at 120°C.

[0029] Put the bamboo charcoal powder in the prepared silica sol and infiltrate it in a vacuum for 8 hours, then take it out and keep it in the oven at 60°C for 3 hours, so that the silica sol will undergo gelation reaction, and continue to dry at 120°C Tumble dry.

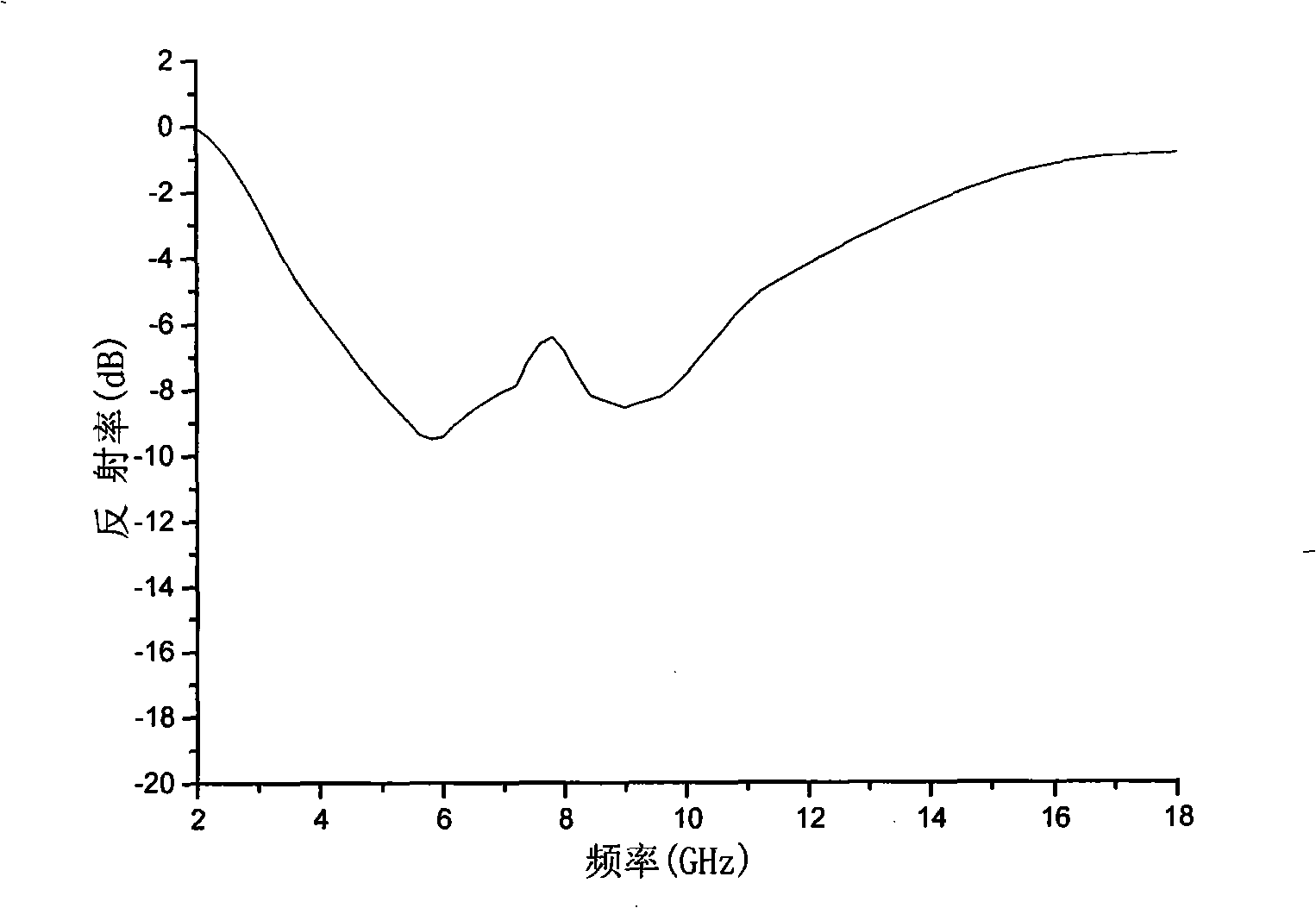

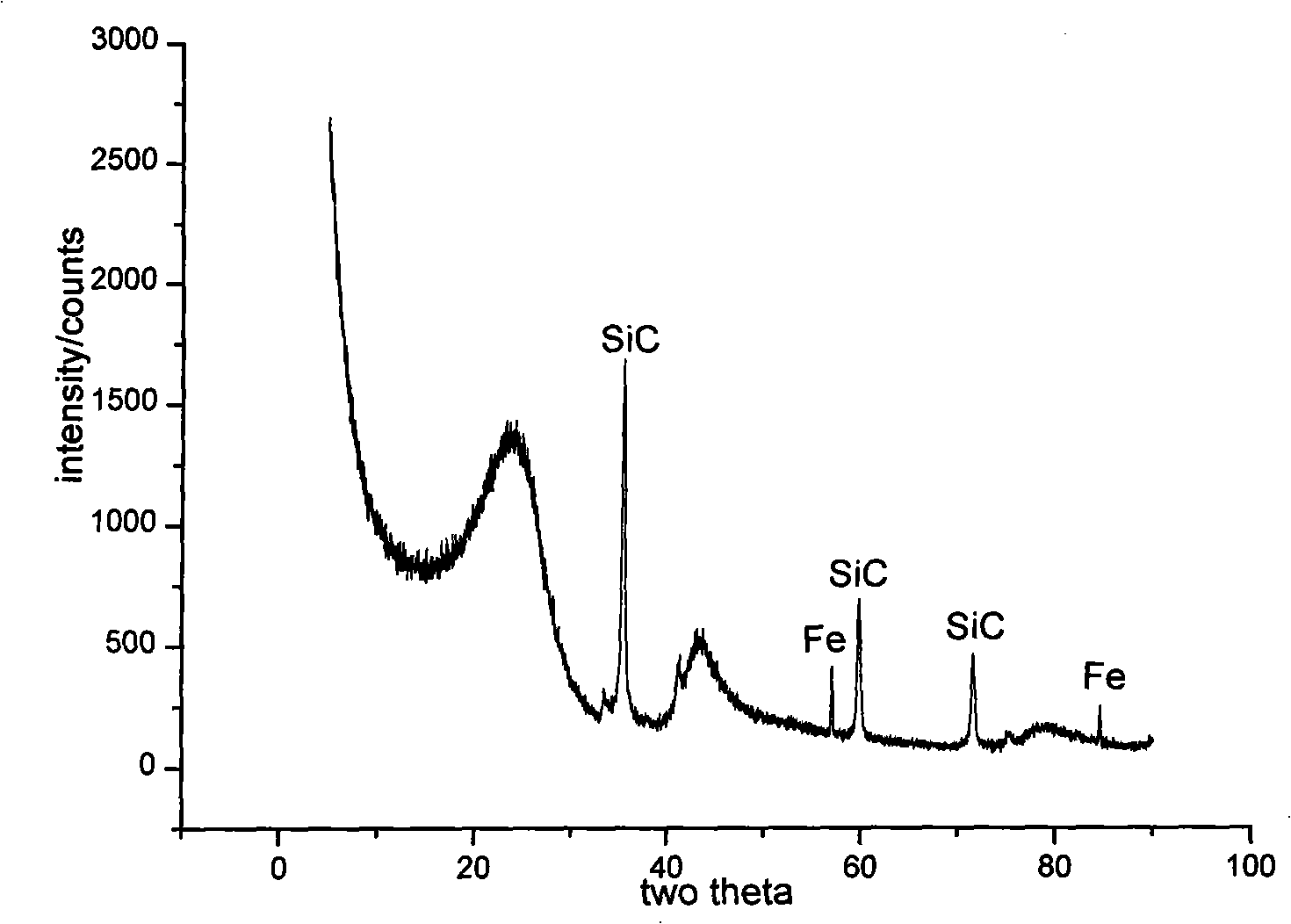

[0030] Finally, the bamboo charcoal powder is placed in a carbonization furnace and carbonized at 1450°C under the protection of nitrogen. The holding time is 2 hours, and the surface cerami...

Embodiment 3

[0033] Cut bamboo slices of 15mm x 6mm x 3mm from moso bamboo, and dry the bamboo slices to remove moisture. The bamboo slices were soaked in a nitric acid solution with a concentration of 2mol / L for 20 hours, then suction filtered and rinsed with deionized water until the pH value of the filtrate was 7. Bamboo slices were dried at 120°C. Bamboo slices were placed in a carbonization furnace for carbonization treatment at 1000°C under nitrogen protection, and the holding time was 1 hour to prepare bamboo charcoal.

[0034] Bamboo charcoal was soaked in 2.5mol / L ferric chloride solution for 12 hours, and then suction filtered. Bamboo charcoal was soaked in 2.5mol / L nickel sulfate solution for 12 hours, and then suction filtered. Bamboo slices were dried at 120°C.

[0035] Put the bamboo charcoal in the prepared silica sol and infiltrate it in vacuum for 12 hours, then take it out and heat it in the oven at 60°C for 5 hours to make the silica sol gelation reaction, and continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com