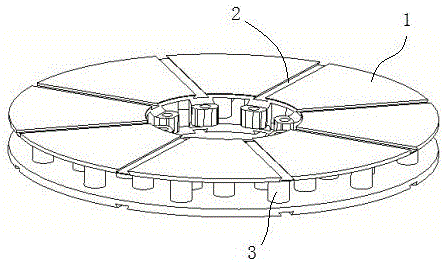

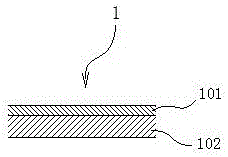

Aluminum-based composite brake disc and manufacturing method

An aluminum-based composite material and brake braking technology, which is applied in the field of brake discs, can solve the problems of high brittleness, difficult processing, and high manufacturing costs, and achieve the effects of low density, improved strength and toughness, and reduced processing and manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

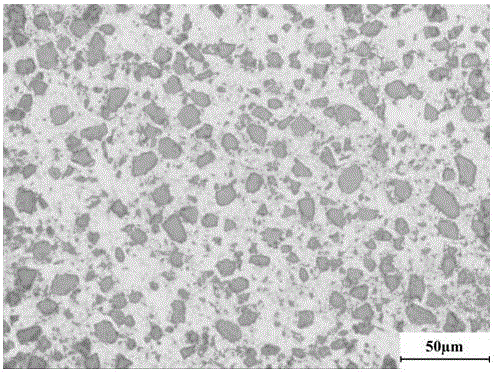

[0040]Firstly, the aluminum alloy disc core is made of aluminum alloy A356 by semi-solid casting, and then the silicon carbide (SiC) particles are pretreated (grinding, screening, cleaning, drying), and then the silicon carbide particles are put into the electric furnace Roast at 1000-1100°C for 100 minutes and then cool naturally, heat aluminum alloy A356 to 665°C to melt, heat silicon carbide particles to 350°C, and stir while adding to the aluminum alloy melt to obtain a composite material. The range of silicon carbide particles is 3μm- 25μm, showing a normal distribution, the weight percentage is 23% of the particle reinforced aluminum matrix composite material, the stirring temperature is controlled at about 580°C, the stirring speed is 1000rpm, and the stirring time is 60 minutes. The stirred composite material is near the melting point of the aluminum alloy Quickly pour into the mold and cool to obtain the ingot of particle reinforced aluminum matrix composite material, ...

Embodiment 2

[0042] Firstly, the aluminum alloy disc core is made by high-pressure casting of aluminum alloy A357, and then the silicon carbide (SiC) particles are pretreated (grinding, screening, cleaning, drying and roasting at 1100°C), and the aluminum alloy A357 is heated to 700°C Melting, heating the silicon carbide particles to 325°C, adding them to the aluminum alloy melt while stirring to obtain a composite material, the silicon carbide particles range from 3 μm to 30 μm, and are normally distributed; the weight percentage is 20% of the particle-reinforced aluminum matrix composite material . The stirring temperature is controlled at about 590°C, the stirring speed is 1200rpm, and the stirring time is 80 minutes; the stirred composite material is quickly poured into the mold near the melting point of the aluminum alloy and cooled to obtain a particle-reinforced aluminum matrix composite ingot, and finally the core is placed Put it into the forming mold of the brake disc body, re-me...

Embodiment 3

[0044] Firstly, the aluminum alloy disc core is made by low-pressure casting of aluminum alloy A319, and then aluminum oxide (Al 2 o 3 ) particles for pretreatment (grinding, screening, cleaning, drying), heating the aluminum alloy A319 to 700°C to melt, heating the alumina particles to 400°C, adding them to the aluminum alloy melt while stirring to obtain a composite material, alumina The particle range is 3μm-30μm, and it is normally distributed; the weight percentage is 35% of the particle-reinforced aluminum matrix composite material. The stirring temperature is controlled at about 590°C, the stirring speed is 1500rpm, and the stirring time is 100 minutes; the stirred composite material is quickly poured into the mold near the melting point of the aluminum alloy and cooled to obtain a particle-reinforced aluminum matrix composite ingot, and finally the core is placed Put it into the forming mold of the brake disc body, re-melt the prepared particle-reinforced aluminum mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com