Angular precision positioning device for crank of crankshaft

A precise positioning and angular technology, applied in the direction of grinding workpiece supports, grinding machines, metal processing equipment, etc., can solve the problems of troublesome dovetail or rectangular guide processing, large number of processed parts, and many structural levels, etc., to achieve fast indexing, High production efficiency and wide indexing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

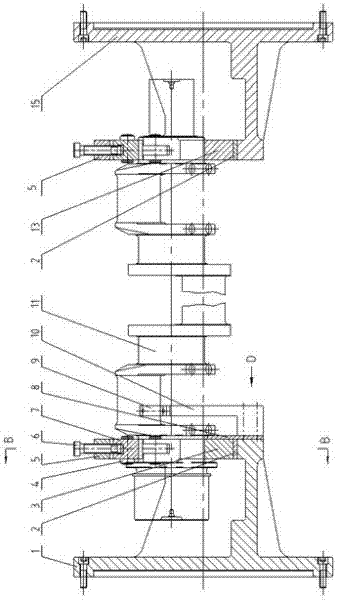

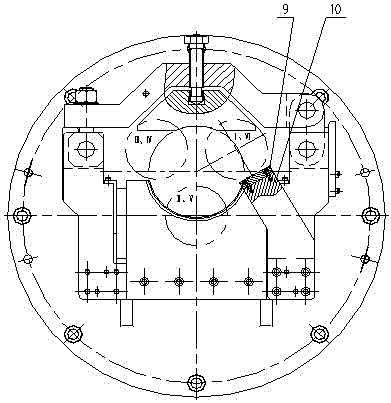

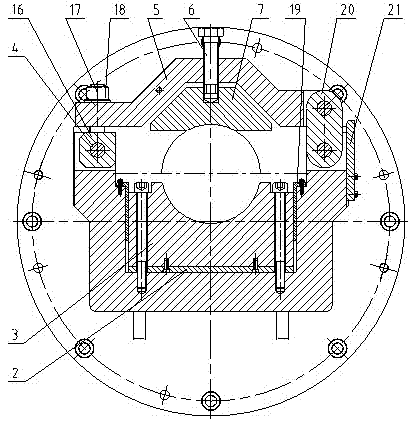

[0021] like Figure 1 to Figure 3 As shown, the present invention is a simple and fast angular precise positioning device for crankshaft crank, including left and right clamping bodies, left and right clamping mechanisms, left and right centering arc blocks, mounted on the left clamping body There are angular precise positioning devices for crankshaft indexing, etc. The left and right clamps are respectively directly installed on the faceplate of the main shaft of the crankshaft grinder without any transition plate, and the eccentricity adjustment mechanism driven by the screw nut is not used.

[0022] The main journal of crankshaft 11 is positioned on the arc surface of left and right arc blocks 3,13 on left and right clamp bodies 1,15, and the arc size of left and right arc blocks 3,13 is the same as that of crankshaft 11. The size of the main journ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com