Low-cost high-machinability steel for engineering machine and manufacturing method of steel

A technology of engineering machinery and mechanical processing, which is applied in the field of low-cost, high-machinability steel for engineering machinery and its manufacturing, and can solve problems such as ultra-high-strength steel plates that have not been pointed out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

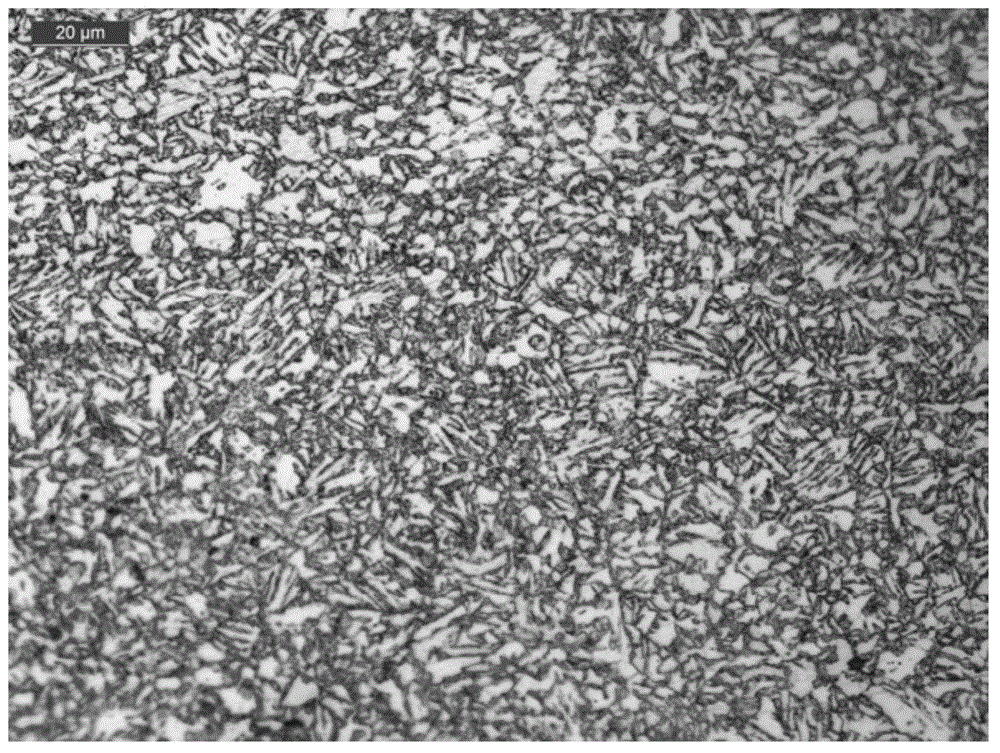

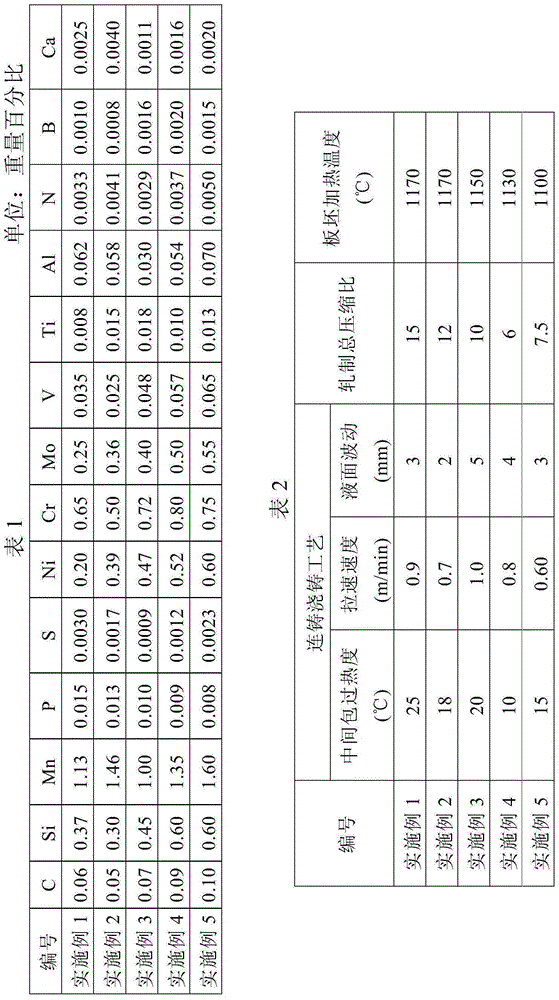

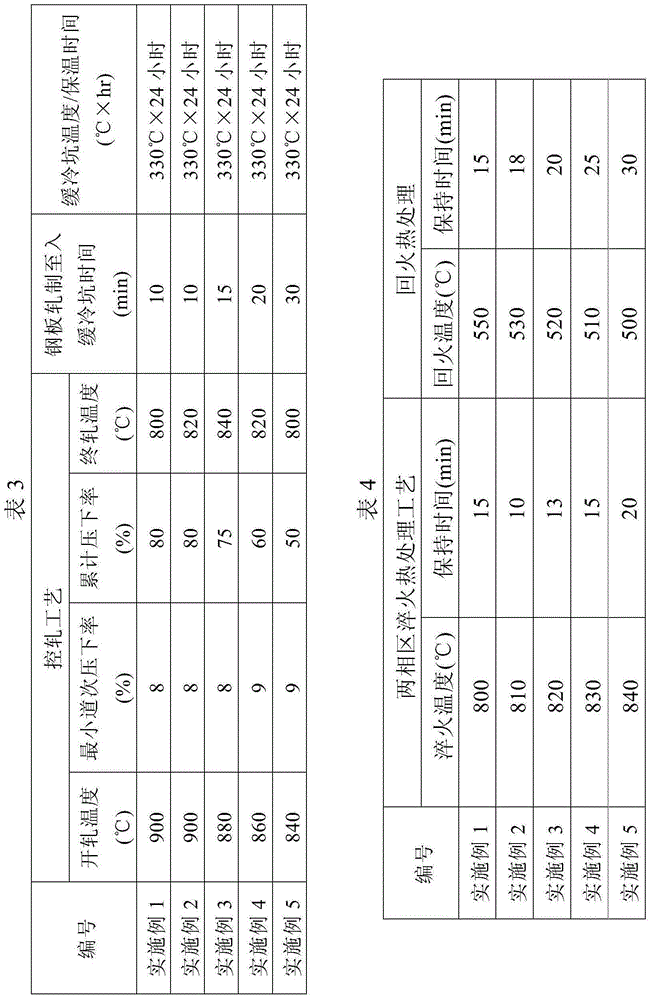

[0051] The composition of the embodiment of the present invention is referring to Table 1, and Table 2, Table 3, and Table 4 are embodiments of the manufacturing process of the present invention; Table 5 is the performance of the steel plate of the embodiment of the present invention, figure 1 It is a photo of the microstructure (1 / 4 thickness) of Example 3 of the present invention.

[0052] Depend on figure 1 It can be seen that the microstructure of the steel plate is very fine and uniform, and the microstructure type is a multiphase structure--dispersed distribution of ferrite + tempered bainite / martensite, and the volume fraction of ferrite is about 20% to 30%. %, the bainite / martensite packet size is fine and uniform, and the average packet size is below 20 μm. While the quenched and tempered steel plate has high strength, it can obtain excellent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com