Carbon quantum dot and green preparation method and application thereof

A carbon quantum dot and green technology, applied in the field of carbon quantum dots and their green preparation, can solve problems such as high cost, complex equipment, safety risks and environmental pollution, and achieve low equipment requirements, easy process control, and good biocompatibility. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A green preparation method of carbon quantum dots, specifically comprising the following steps:

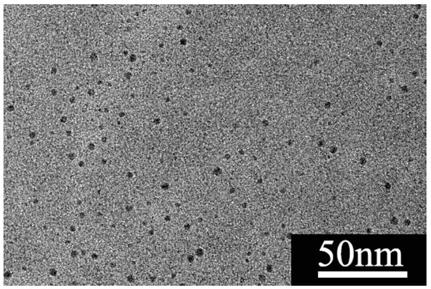

[0034] Dissolve 0.1g of soluble starch in 30mL of water, stir and heat to 60°C until completely dissolved, then add 1mL of 1mol / L NaOH solution, continue stirring for 10min after mixing, and place the obtained transparent mixed solution in a 50mL autoclave (i.e. hydrothermal kettle), heated to 200°C, and kept warm for 3 hours to obtain a dispersion; 200W of the dispersion was ultrasonically dispersed for 2 hours, and then centrifuged at a speed of 15,000rpm for 20 minutes to obtain an upper layer solution; the obtained upper layer solution was placed in - Freeze-drying at 70°C for 48 hours can obtain a specific surface area of 1321m 2 / g, carbon quantum dots with a particle size of 5-10nm and a purity greater than 99%.

Embodiment 2

[0036] A green preparation method of carbon quantum dots, specifically comprising the following steps:

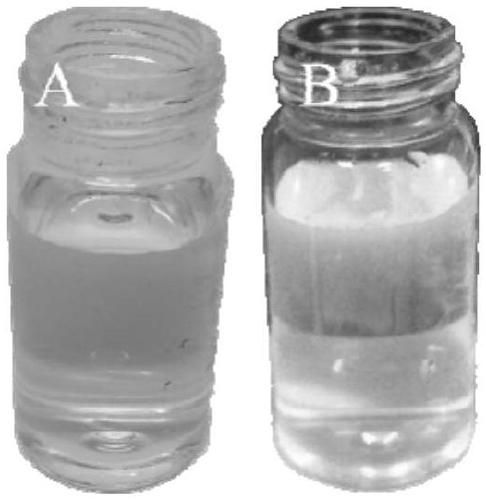

[0037]Dissolve 0.1g of soluble starch in 30mL of water, stir and heat to 60°C until completely dissolved, then add 1mL of 1mol / L dilute nitric acid solution, mix and continue to stir for 10min, and place the obtained transparent mixed solution in a 50mL autoclave (that is, water hot kettle), heated to 200°C, and kept warm for 3 hours to obtain a dispersion; 200W of the dispersion was ultrasonically dispersed for 2 hours, and then centrifuged at a speed of 15000 rpm for 20 minutes to obtain an upper layer solution; the obtained upper layer solution was used A dialysis bag with a molecular weight cut-off of 1000Da was used for dialysis separation, placed in distilled water for dialysis for 6 days, and the water was not changed during the dialysis process. The solution outside the dialysis bag was collected to obtain a carbon quantum dot solution; the obtained carbon quantum do...

Embodiment 3

[0039] A green preparation method of carbon quantum dots, specifically comprising the following steps:

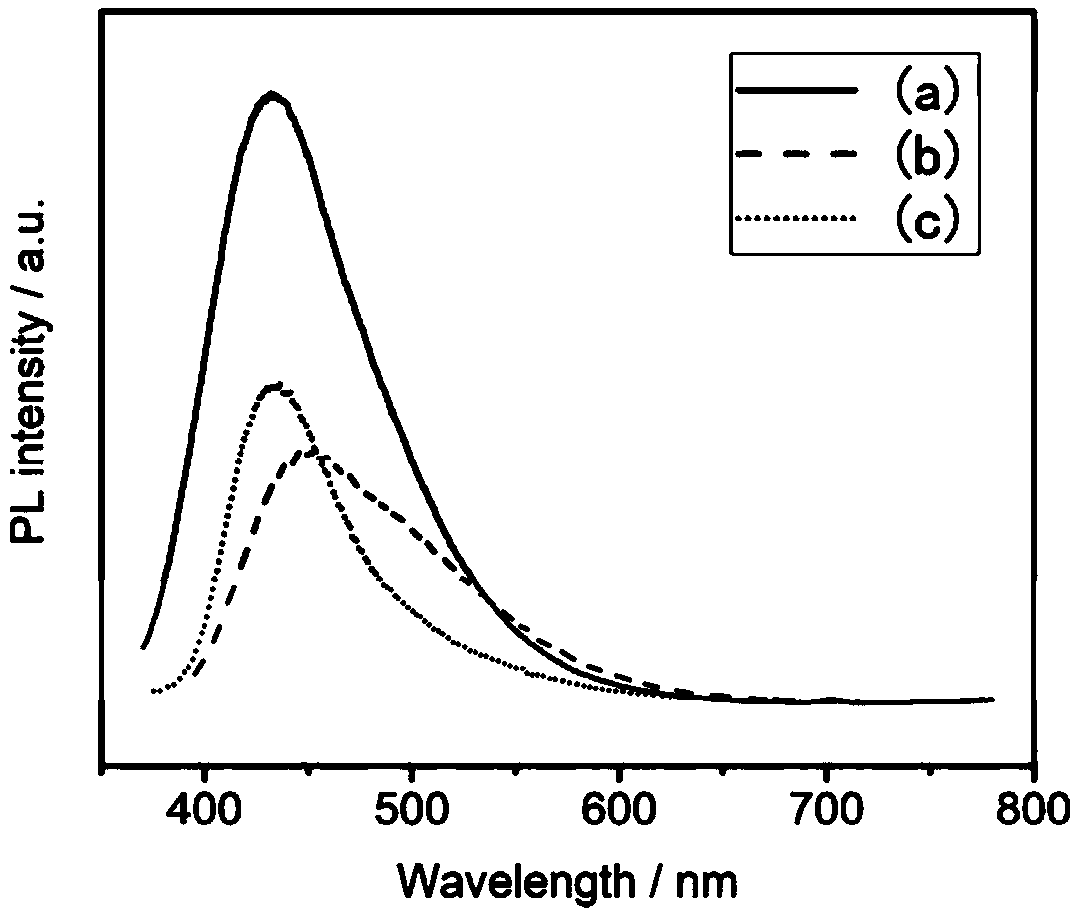

[0040] Dissolve 0.1g of carboxymethyl cellulose in 30mL of water, stir and heat to 70°C until completely dissolved, then add 1mL of 1mol / L NaOH solution, mix and continue stirring for 10min, and place the obtained transparent mixed solution in a 50mL autoclave ( (i.e., sealed in a hydrothermal kettle), heated to 180°C, and kept warm for 5 hours to obtain a dispersion; 200W of the dispersion was ultrasonically dispersed for 2 hours, and then centrifuged at a speed of 15000rpm for 10 minutes to obtain an upper layer solution; the obtained upper layer The solution was separated by dialysis with a dialysis bag with a molecular weight cut-off of 1000Da, placed in 30ml of distilled water for dialysis for 6 days, no need to change the water during the dialysis process, and the solution outside the dialysis bag was collected to obtain a carbon quantum dot solution. The fluorescence...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com