Multi-parameter controllable high-rotating speed mechanical sealing performance tester

A technology of mechanical seal and test device, which is applied in the testing of fluid tightness, measuring device, testing of mechanical parts, etc., can solve the problems of few measurement parameters, difficult measurement of end-face friction torque, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

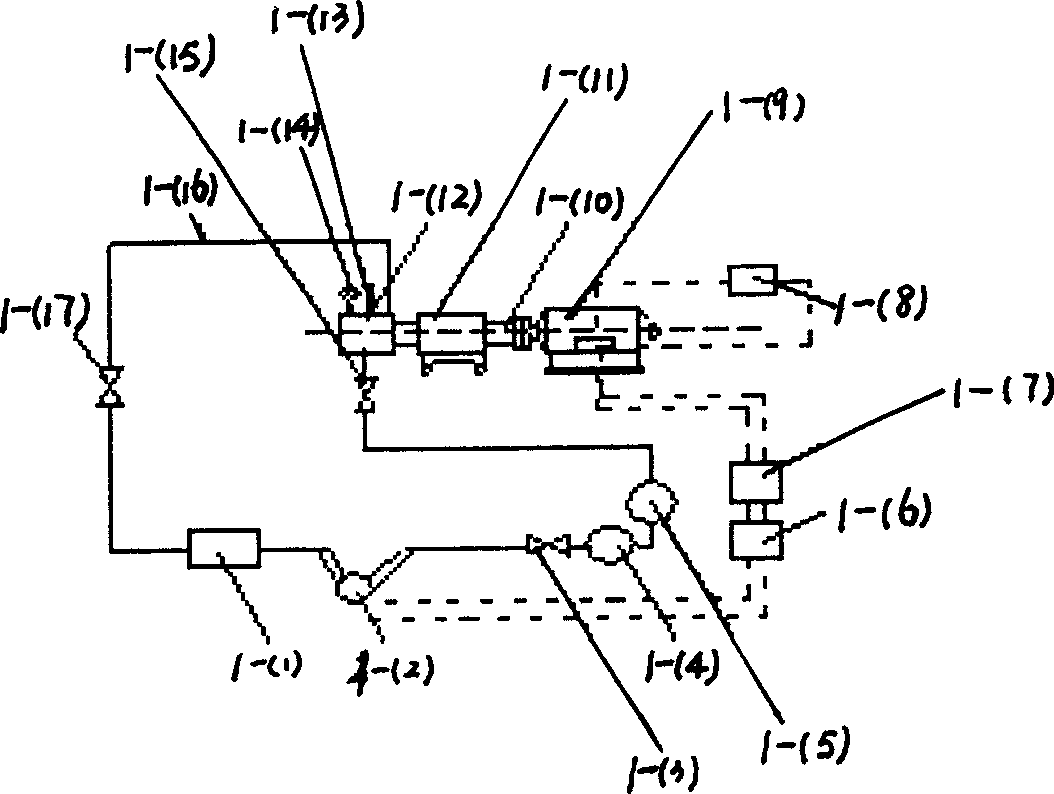

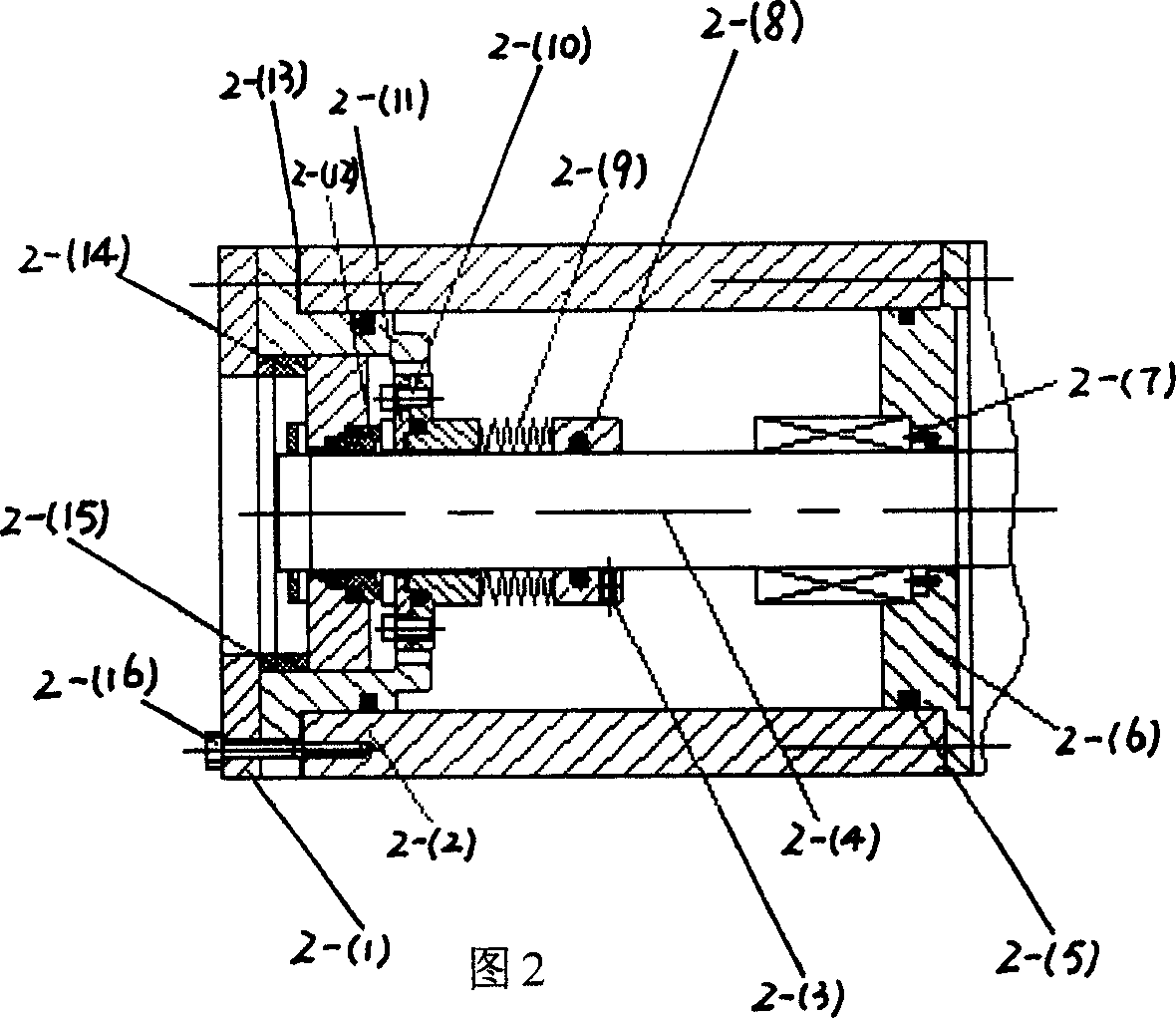

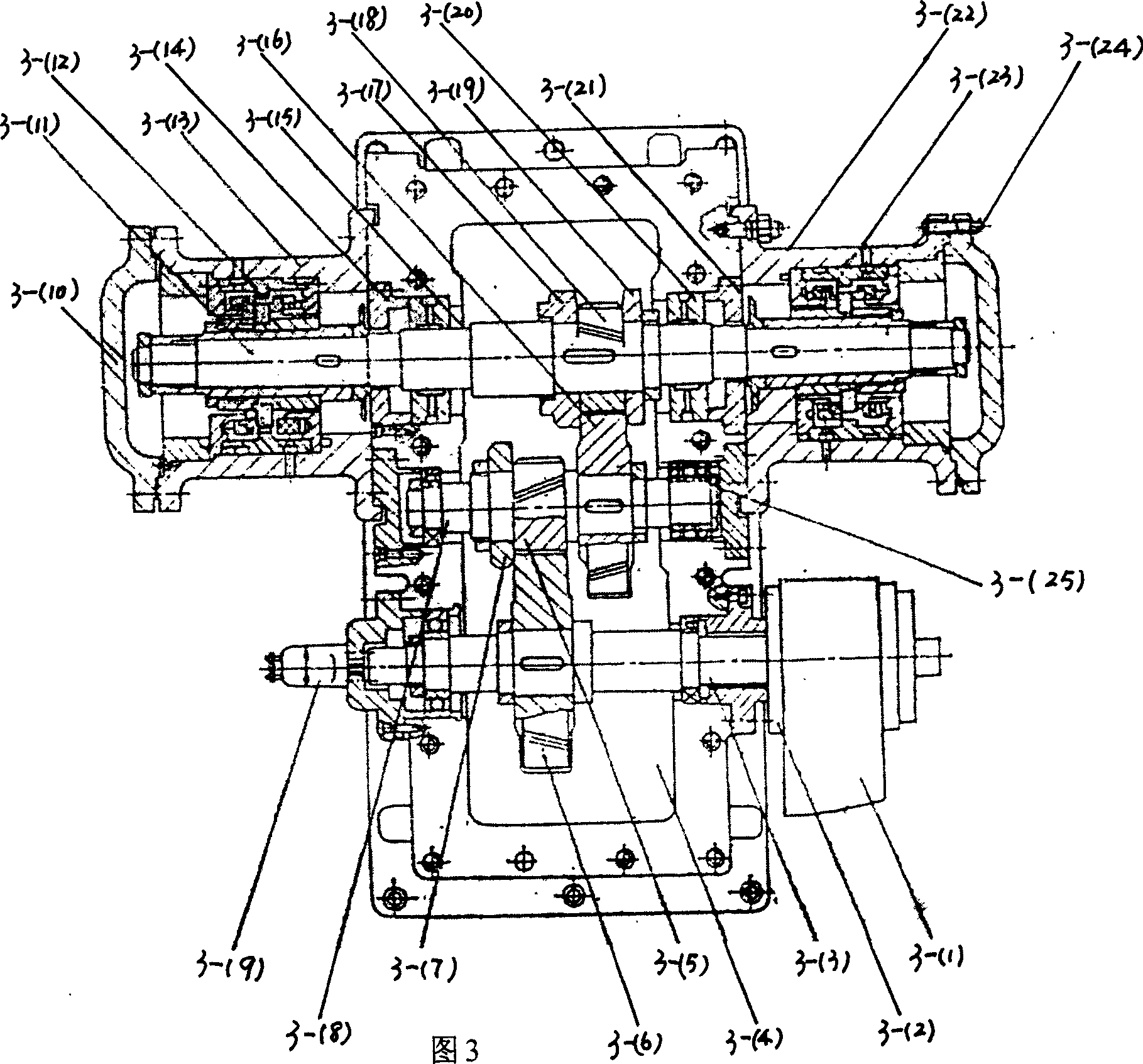

[0064] Such as Figure 5-1 3 is a specific embodiment of the "multi-parameter measurable and controllable high-speed mechanical seal performance test device" of the present invention. The parameters of the sensors used are shown in Table 6, and the components used in the control system refer to Figure 12 .

[0065] serial number

name

quantity

Specification

Range

precision

purpose

1

Thin film platinum resistance temperature measuring element

3

STTT-T

0~200℃

1 / 3DIN

Measuring ring temperature

2

Temperature Sensor

1

STTT-T

0~200℃

0.5%

Measuring medium temperature

3

1

NS-G

0~2Mpa

0.5%

Measuring medium pressure

4

Linear Displacement Sensor

1

NS-WY01

0~10mm

0.002mm

Measuring end face specific pressure

5

Angular displacement sensor

1

NSRB

0~30

0.2%

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com