Novel process for preparing C-Fe shell-core magnetic active carbon by utilizing waste biomasses

A technology of waste biomass and magnetic activated carbon, which is applied in the field of resource utilization of waste biomass, and can solve problems such as in-situ incineration and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

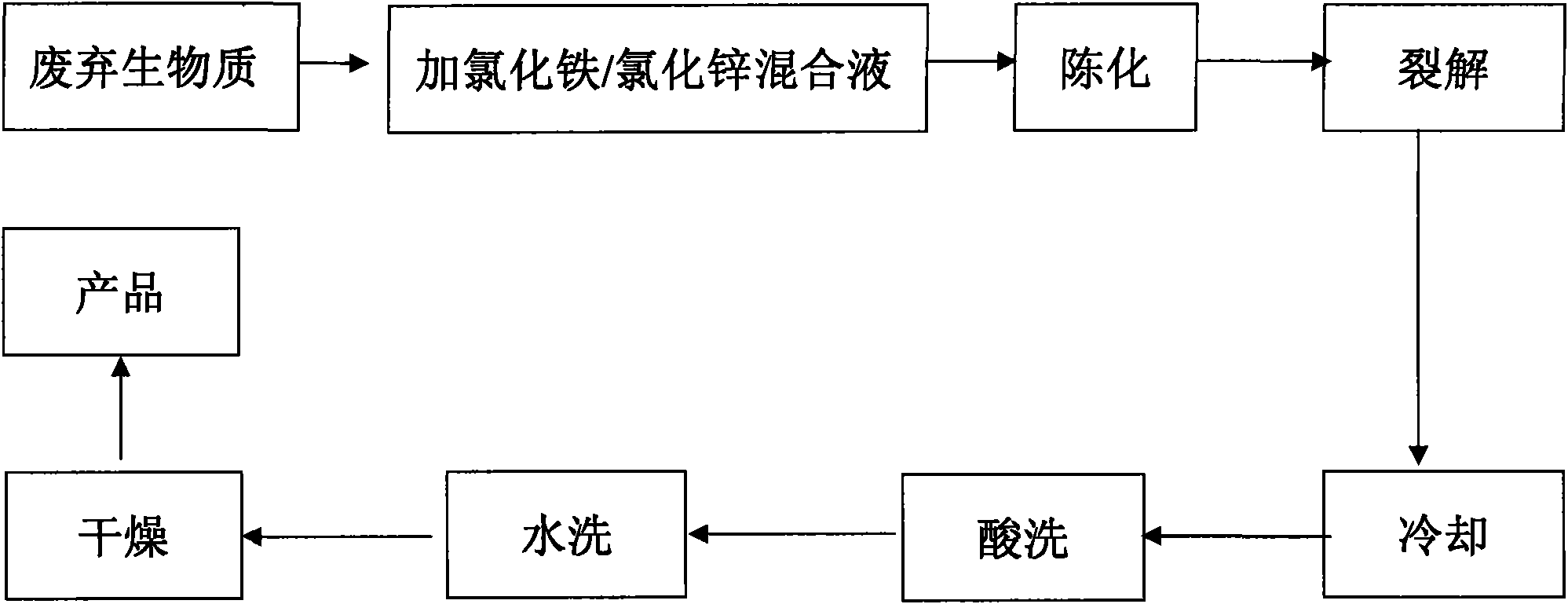

[0008] Mix sawdust with a mixed solution of ferric chloride and zinc chloride at a solid-to-liquid ratio of 1:5 (the mass ratio of sawdust, ferric chloride and zinc chloride is 20:1:10), and age at 60° C. for 6 hours. Then the obtained mixture was put into a cracking furnace, and under the protection of a nitrogen atmosphere, the heating rate was raised to 700° C. for cracking at a rate of 5° C. / min. The cracking time was 30 minutes. After the heating was stopped, it was naturally cooled to room temperature under the protection of nitrogen. The product obtained by the reaction is washed with dilute acid and deionized water respectively, and then dried to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com