Vibration motor electronic equipment

A vibration motor and driving force technology, applied in the mechanical field, can solve the problems of single vibration feedback and inability to achieve multi-directional vibration feedback.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

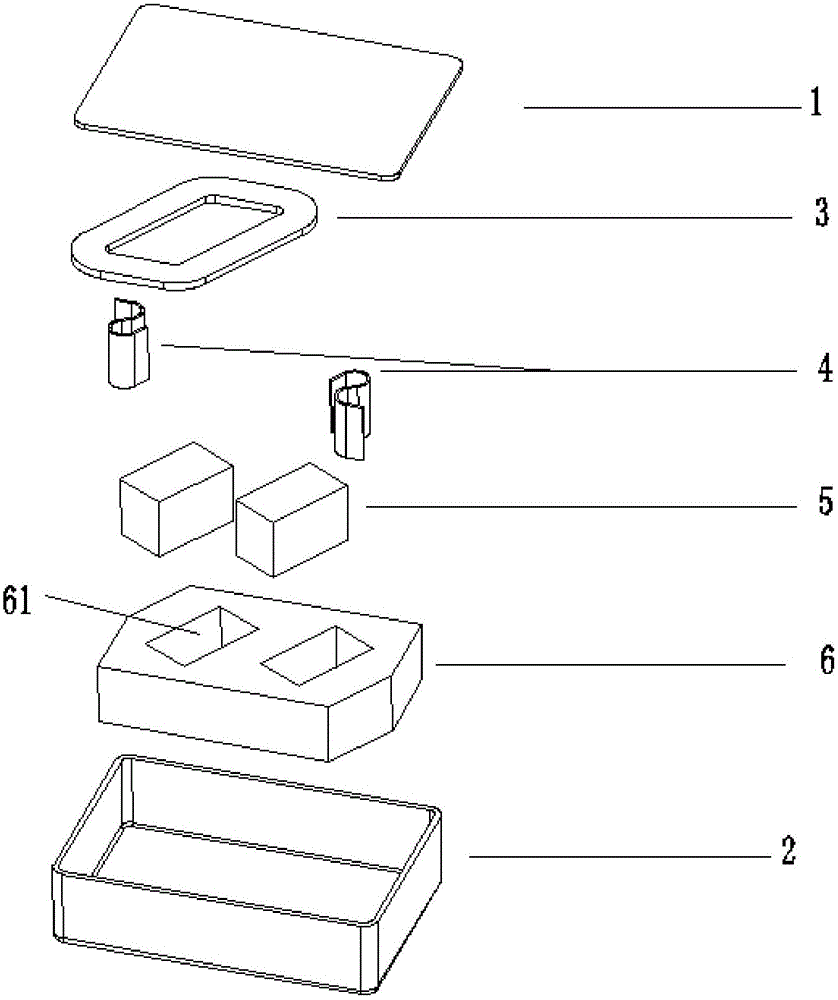

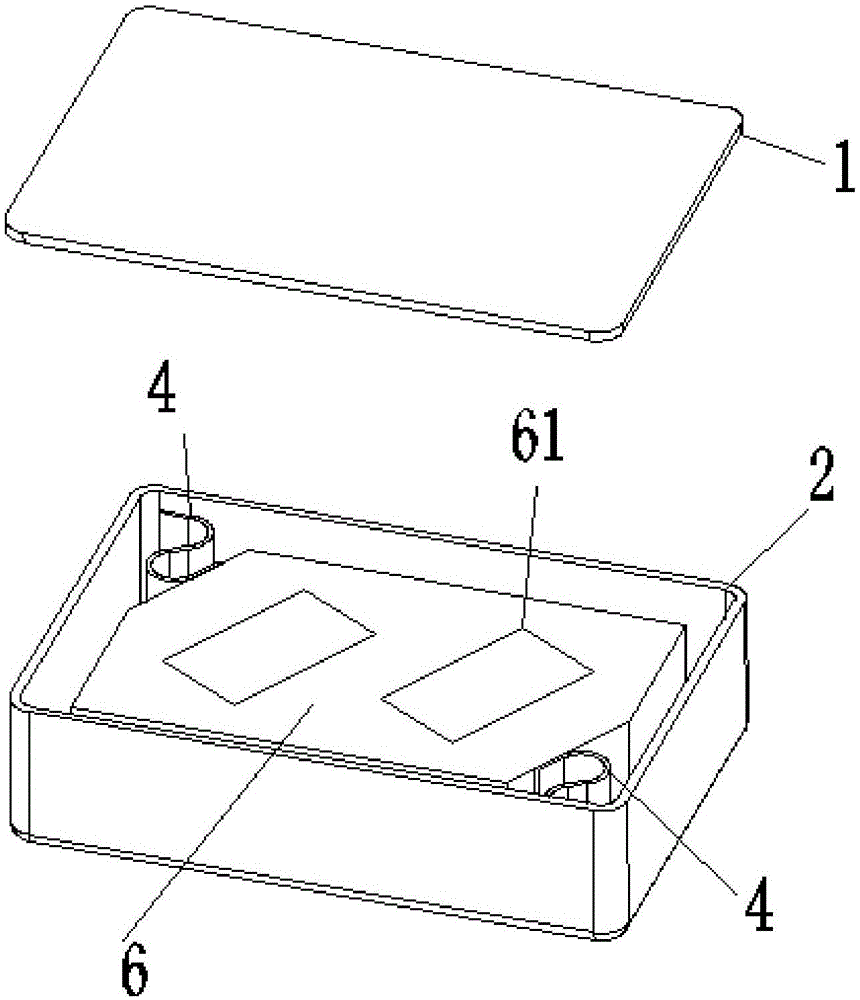

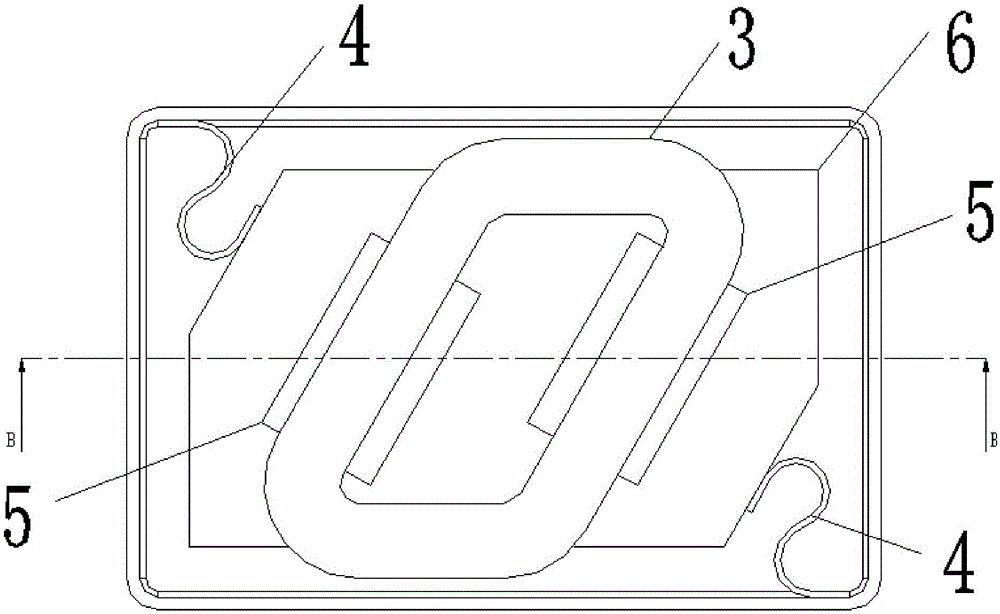

[0032] figure 1 An exploded view of the vibration motor provided in Embodiment 1 of the present invention, figure 2 for figure 1 The schematic diagram of the assembled body of the vibration motor in , image 3 is the top view of 2, Figure 4 for image 3 Sectional view at BB.

[0033] like Figure 1 to Figure 4 As shown collectively, the vibration motor of this embodiment includes a casing composed of an upper casing 1 and a lower casing 2 , and the cavity surrounded by the casing accommodates a coil 3 , shrapnel 4 , magnet 5 and mass 6 .

[0034] The mass block 6 has an accommodating groove 61 adapted to the outline of the magnet 5, and the magnet 5 is accommodated in the accommodating groove 61 for providing a magnetic field for the vibration motor;

[0035] The coil 3 is fixed on the upper shell 1 and is connected to an external power source for inductively generating a driving force with the magnet 5 when energized;

[0036] A shrapnel 4 is arranged at a pair of co...

Embodiment 2

[0047] like Image 6 As shown, the vibration motor of this embodiment also includes a pot frame 7, which is fixed on the upper shell 1 and has a housing structure 71 adapted to the outline of the coil 3, and the coil 3 is embedded in the housing structure 71 of the pot frame 7 ; Wherein, the frame 7 is a soft magnetic metal magnetic material.

[0048] In this embodiment, the coil is embedded in a frame made of magnetically conductive material, and the frame is used to gather and constrain the self-diverging magnetic field lines in the magnetically conductive material, and transmit it to the power system part of the vibration motor to achieve The purpose of improving the utilization rate of magnetic induction lines and improving the vibration performance of the motor. In practical applications, the vibration motor of the present invention may also include structures such as washer boards and edge washer, so as to further improve the utilization rate of magnetic induction lines...

Embodiment 3

[0050] This embodiment provides an electronic device, including the first embodiment and / or the vibration motor provided by the embodiment, and utilizes the characteristic of the motor's diagonal vibration to realize multi-directional tactile and vibration feedback experiences of the device, thereby improving user experience.

[0051] The electronic equipment in this embodiment can better adapt to the development requirements for precision miniaturization, fast pace, high quality and low cost by using the vibration motor.

[0052]In summary, the present invention provides a vibrating motor and electronic equipment. The mass block of the vibrating motor is connected to the diagonal of the housing by a shrapnel, so that the magnet embedded in the mass block can realize diagonal vibration during electromagnetic induction. . Diagonal vibrating motors can not only achieve multi-directional vibration effects of X-direction vibration and Y-direction vibration, resulting in a better u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com