Method for forming large complex thin-wall shell with circumferential inner ribs

A thin-walled shell and forming belt technology, which is applied to the field of large and complex thin-walled shells with annular inner ribs of forming belts, can solve the problems of high cost, complicated spinning process, and difficulty in changing molds and adjusting molds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

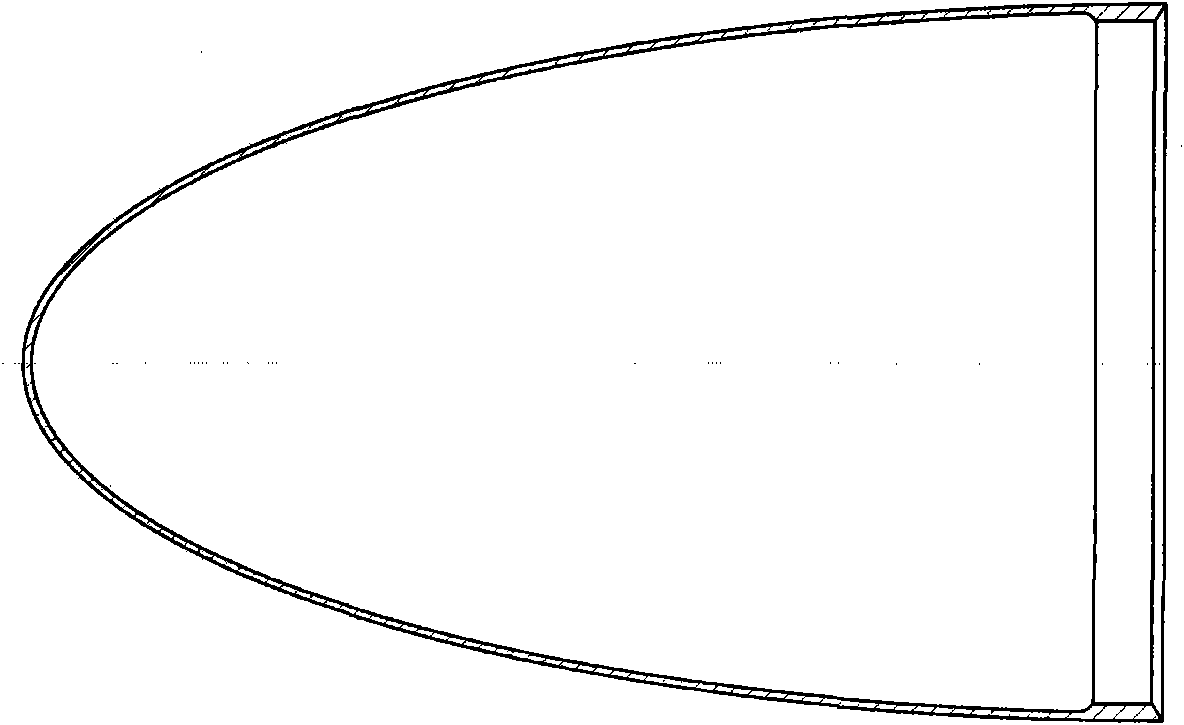

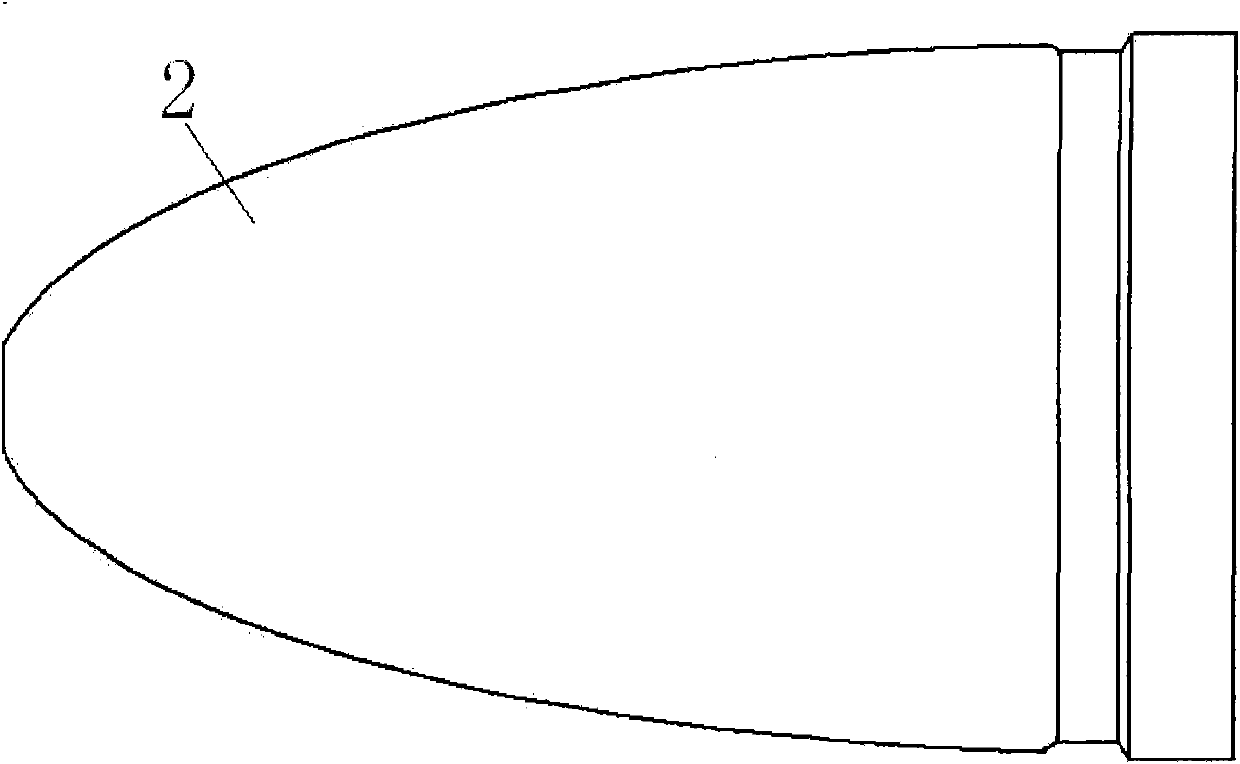

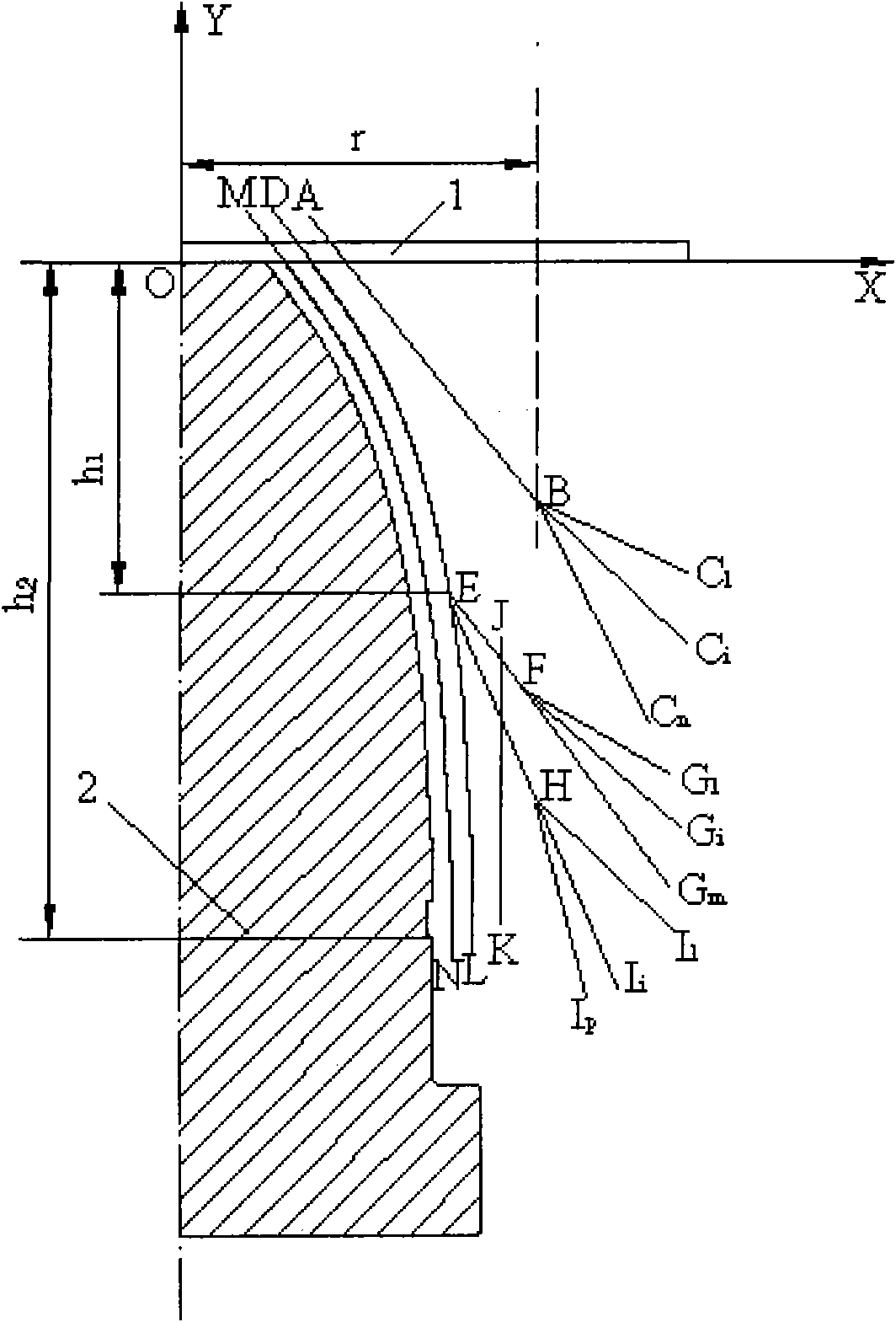

[0048] This embodiment is a large-scale complex thin-walled shell with ring-shaped inward ribs at the mouth of a certain spacecraft. The shape of the part is as follows: figure 1 As shown, the material is 3A21, the thickness of the non-rib part is t=1.5mm, and the maximum wall thickness of the rib part is t max = 4.35 mm. Specific steps are as follows:

[0049] Step 1, determine the blank size;

[0050] Take the thickness allowance Δt=0.65mm, according to the formula (1), the thickness t of the slab 1 is obtained 0 = 5mm.

[0051] t 0 = t max +Δt (1)

[0052] In formula (1), t 0 is the thickness of slab 1, t max is the maximum thickness of the rib part of the spinning part, Δt is the thickness allowance, and Δt=0.5~1.0mm.

[0053] According to the part drawing, the volume of the part is determined to be 448186mm 3 , considering the machining allowance ΔD = 62mm, substituting into the formula (2) to get the diameter D of the slab 1 0 = 400mm.

[0054] ...

Embodiment 2

[0086] This embodiment is a large-scale complex thin-walled shell with ring-shaped inward ribs at the mouth of a certain spacecraft. The shape of the part is as follows: figure 1 As shown, the material is 3A21, the thickness of the non-rib part is t=1.5mm, and the maximum wall thickness of the rib part is t max = 4.35 mm. Specific steps are as follows:

[0087] Step 1, determine the blank size;

[0088] Take the thickness allowance Δt=0.5mm, according to the formula (1), the thickness t of the slab 1 is obtained 0 = 4.85 mm.

[0089] t 0 = t max +Δt (1)

[0090] In formula (1), t 0 is the thickness of slab 1, t max is the maximum thickness of the rib part of the spinning part, Δt is the thickness allowance, and Δt=0.5~1.0mm.

[0091] According to the part drawing, the volume of the part is determined to be 448186mm 3 , considering the machining allowance ΔD = 50mm, substituting into the formula (2) to get the diameter D of the slab 1 0 = 393mm.

[0092] ...

Embodiment 3

[0124] This embodiment is a large-scale complex thin-walled shell with ring-shaped inward ribs at the mouth of a certain spacecraft. The shape of the part is as follows: figure 1 As shown, the material is 3A21, the thickness of the non-rib part is t=1.5mm, and the maximum wall thickness of the rib part is t max = 4.35 mm. Specific steps are as follows:

[0125] Step 1, determine the blank size;

[0126] Take the thickness allowance Δt=1.0mm, according to the formula (1), the thickness t of the slab 1 is obtained 0 = 5.35 mm.

[0127] t 0 = t max +Δt (1)

[0128] In formula (1), t 0 is the thickness of slab 1, t max is the maximum thickness of the rib part of the spinning part, Δt is the thickness allowance, and Δt=0.5~1.0mm.

[0129] According to the part drawing, the volume of the part is determined to be 448186mm 3 , considering the machining allowance ΔD = 70mm, substituting into the formula (2) to get the diameter D of the slab 1 0 = 397mm.

[0130] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com