A mold clamping device and an operating method of the mold clamping device

A mold clamping device and action technology, applied in the field of mold clamping devices, can solve the problems of time-consuming supply, inability to shorten the forming cycle time, and inability to compact the hydraulic circuit, and achieve the effect of shortening the forming cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

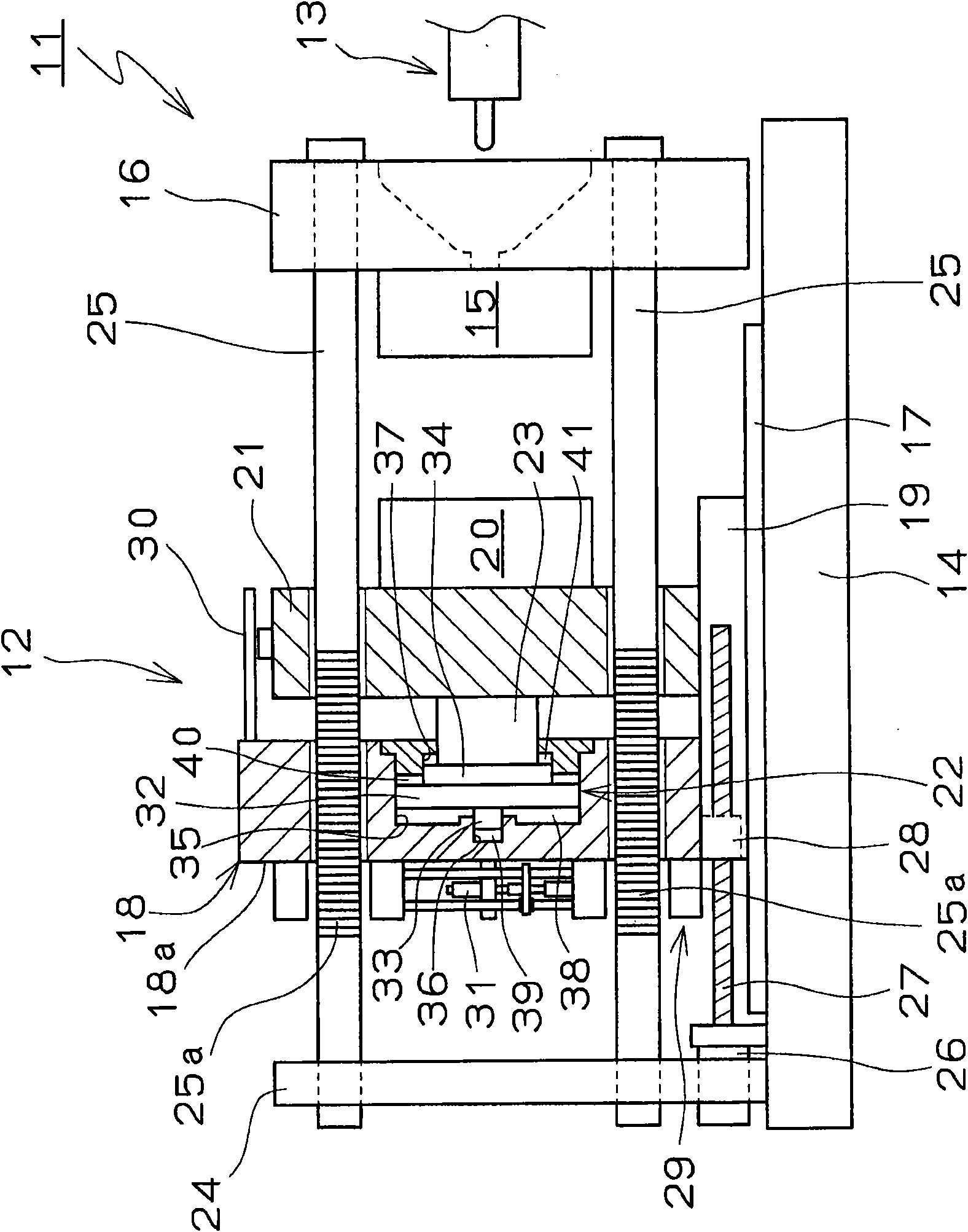

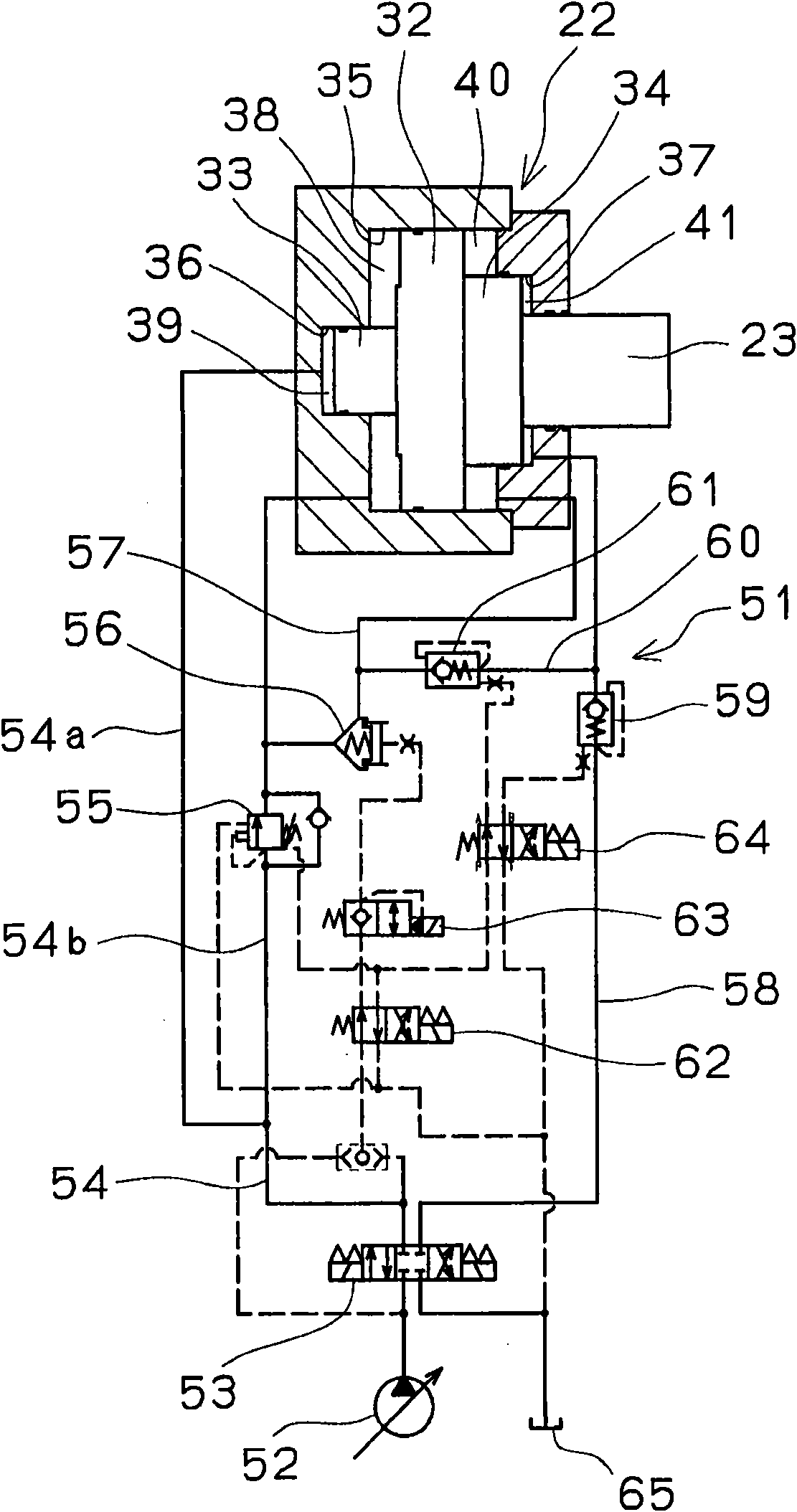

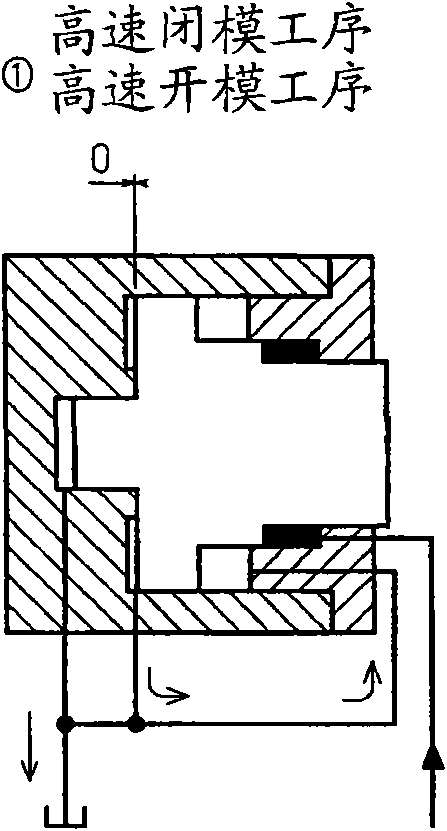

[0042] refer to figure 1 The mold clamping device of the injection molding machine according to the embodiment of the present invention will be described. The injection molding machine 11 basically includes a mold clamping device 12 provided on one side and an injection device 13 provided on the other side. When the mold clamping device 12 is described, a fixed plate 16 on which the fixed metal mold 15 is mounted is erected on the other side (injection device side) of the base 14 . Further, on the base 14, a linear motion guide 17 is fixed toward the mold opening and closing direction, and a movable mold clamping plate 18 is provided on the linear motion guide 17 so as to be movable in the mold opening and closing direction. Furthermore, on the movable mold clamping plate 18, a stand 19 as a foot portion is integrally fixed toward the fixed plate side, and on the stand 19, a mounting bracket is provided so as to be movable relative to the movable mold clamping plate 18 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com