Method for preparing lithiumion cell positive material Iron-lithium phosphate

A lithium-ion battery, lithium iron phosphate technology, applied in the direction of electrode manufacturing, battery electrodes, secondary batteries, etc., can solve problems such as difficulties, and achieve the effects of no three wastes discharge, simple and easy-to-operate process, and simple and easy methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

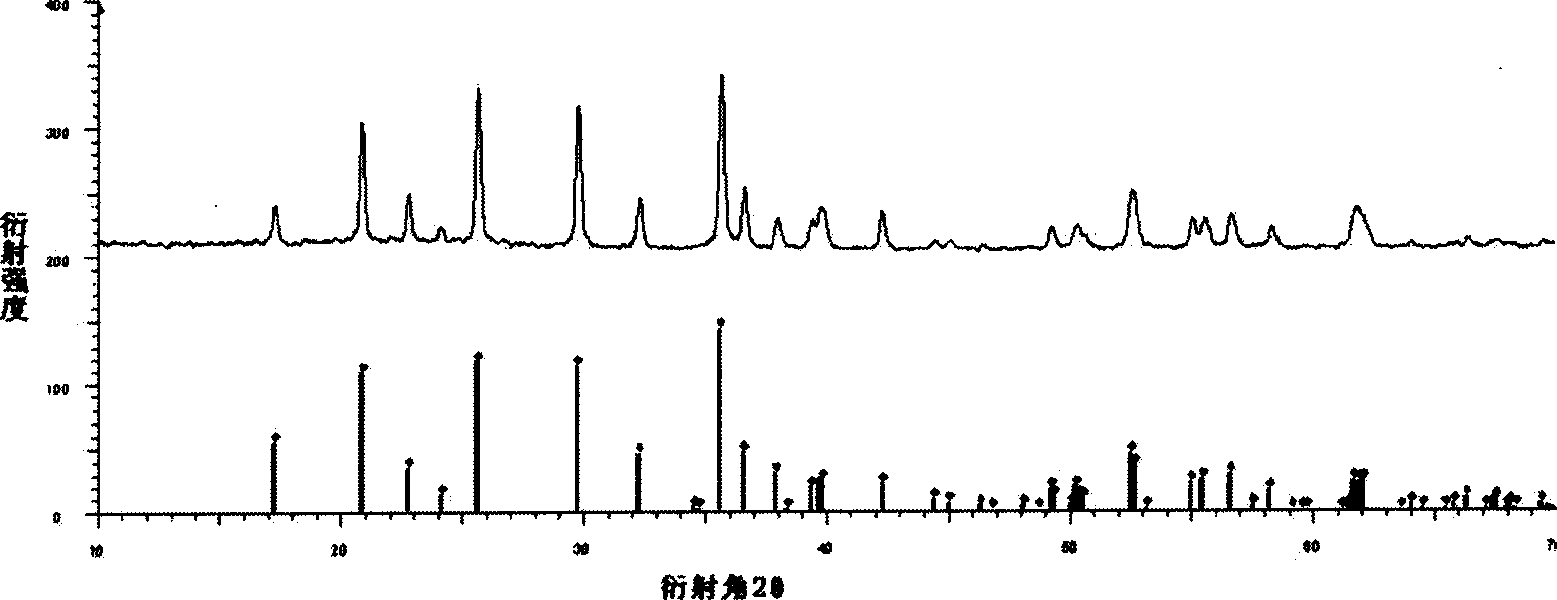

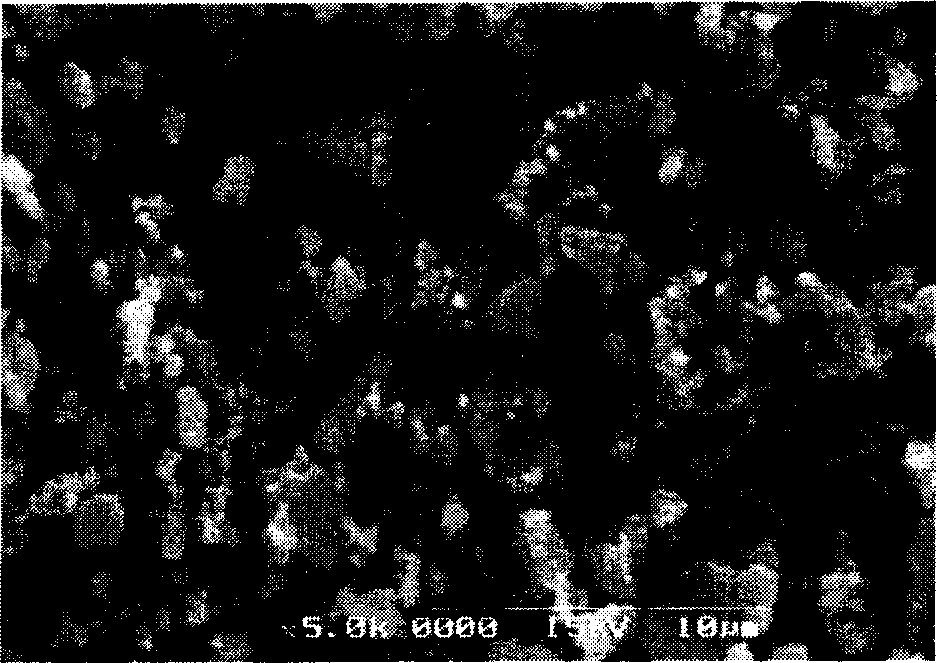

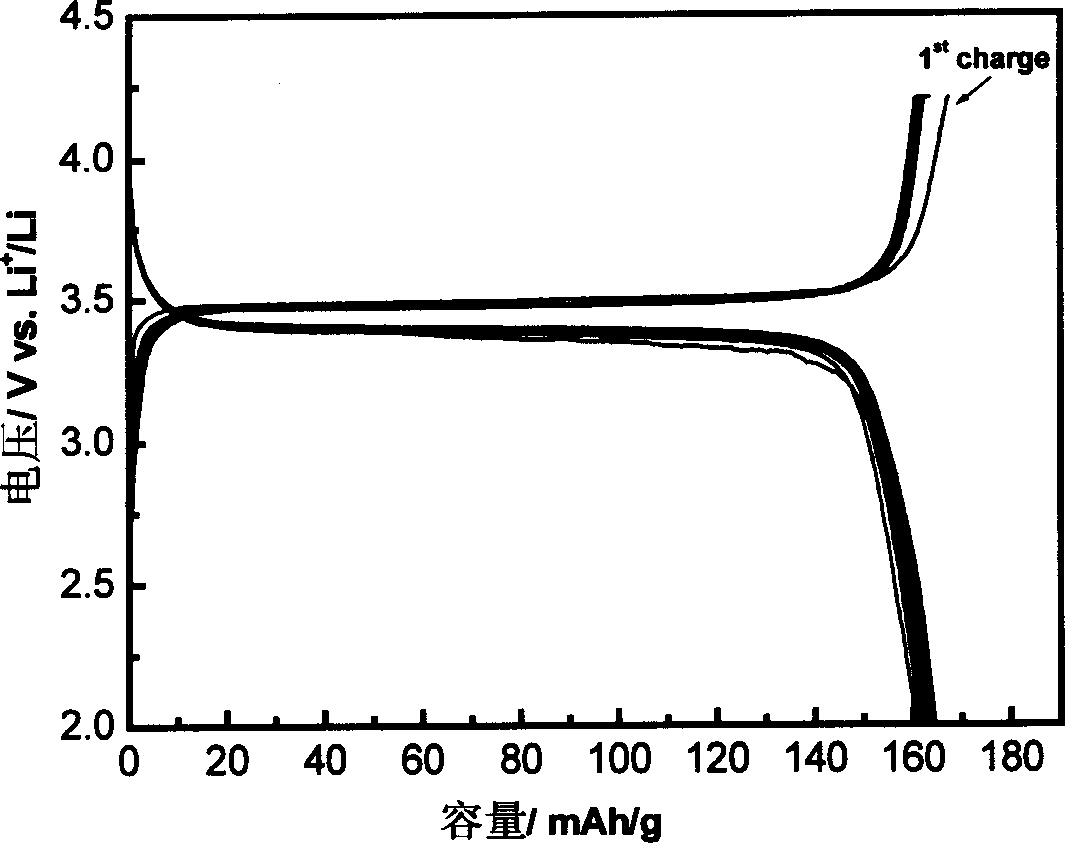

[0030] 2.86 grams (0.05 moles) of iron powder, 15.1 grams (0.1 moles) of iron phosphate, 6.37 grams (0.05 moles) of lithium phosphate and 2.25 grams of sucrose were mixed evenly. The mixture was placed in an agate jar filled with argon and ball milled for 24 h. The ball-milled product was placed in a high-temperature furnace, heated at a heating rate of 10°C / min in an argon atmosphere, and fired at a constant temperature of 600°C for 30 minutes, and then cooled to room temperature at a cooling rate of 20°C / min to obtain LiFePO 4 / C powder. figure 1 X-ray diffraction analysis results show that the prepared lithium iron phosphate powder is olivine-type LiFePO 4 Single-phase structure, there is no impurity peak in the spectrum, and the product has high purity. figure 2 is LiFePO 4 / C powder magnified 5000 times electron micrograph, the particle size of the product is basically less than 5 microns.

[0031] Weigh 0.8 g of the obtained lithium iron phosphate powder, add 0.1 g ...

Embodiment 2

[0034] 78 g Mn(NH 4 ) 2 (SO 4 ) 2 .6H 2 O and 23 g NH 4 h 2 PO 4 Dissolve in 1000ml of deionized water, after mixing the two solutions, add 8ml of 30% H 2 o 2 aqueous solution, stirring was continued for 2 hours. The resulting precipitate was filtered, washed, dried, and then calcined at 400 °C for 4 hours to obtain MnPO 4 . 2.86 grams (0.05 moles) of iron powder, 8.31 grams (0.055 moles) of FePO 4 , 6.75 grams (0.045 moles) of MnPO 4 and 6.37 g (0.05 mol) Mix with 2.25 grams of sucrose, prepare LiFe by the method of embodiment 1 0.7 mn 0.3 PO 4 / C powder. When the obtained product is discharged at a rate of 0.2C, the specific capacity is about 146mAh / g, and the discharge curve voltage is 3.8V-2.9V.

Embodiment 3

[0036] Weigh 41 grams of Ni(NH 4 ) 2 (SO 4 ) 2 .6H 2 O and 12 g NH 4 h 2 PO 4 Dissolve in 500ml of deionized water respectively, after mixing the two solutions, add 4ml of 30% H 2 o 2 aqueous solution, stirring was continued for 2 hours. The resulting precipitate was filtered, washed and dried, and then calcined at 400°C for 4 hours to obtain NiPO 4 crystals. 2.86 grams (0.05 moles) of iron powder, 12.84 grams (0.085 moles) of FePO 4 , 2.31 grams (0.015 moles) NiPO 4 and 6.37 g (0.05 mol) Mix with 0.8 gram of acetylene black, prepare LiFe by the method of embodiment 1 0.9 Ni 0.1 PO 4 / C powder. The specific capacity of the obtained product is about 143mAh / g when discharged at a rate of 0.2C, and the discharge voltage is about 3.45V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com