Silver nanowire and preparation method thereof

A technology of silver nanowires and halides, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as environmental hazards, high cost, and impact on applications, so as to avoid synthesis steps and ensure Effect of parallelism and uniform diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 2g of silver chloride and add it to 200mL (0.123g / mL) of trisodium citrate aqueous solution, and ultrasonically obtain a uniform silver chloride dispersion;

[0036] The dispersion liquid was added to the lining of the reaction kettle, and reacted at 140° C. for 200 minutes to obtain a mixture; and the mixture was centrifuged to obtain the silver nanowires.

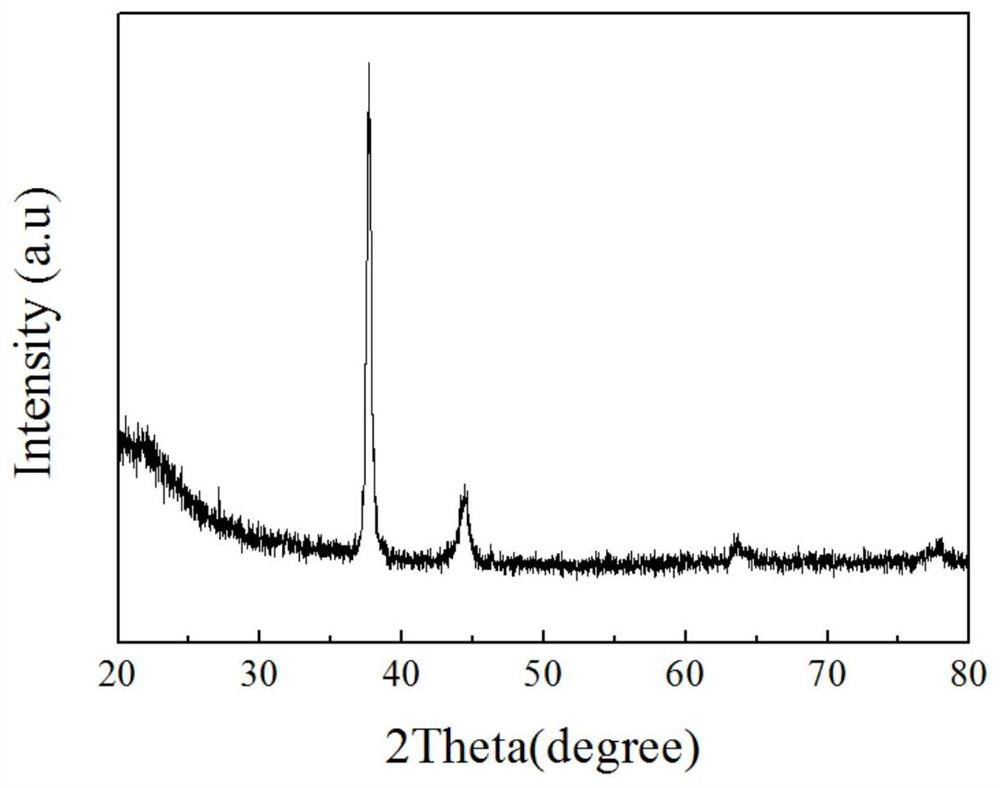

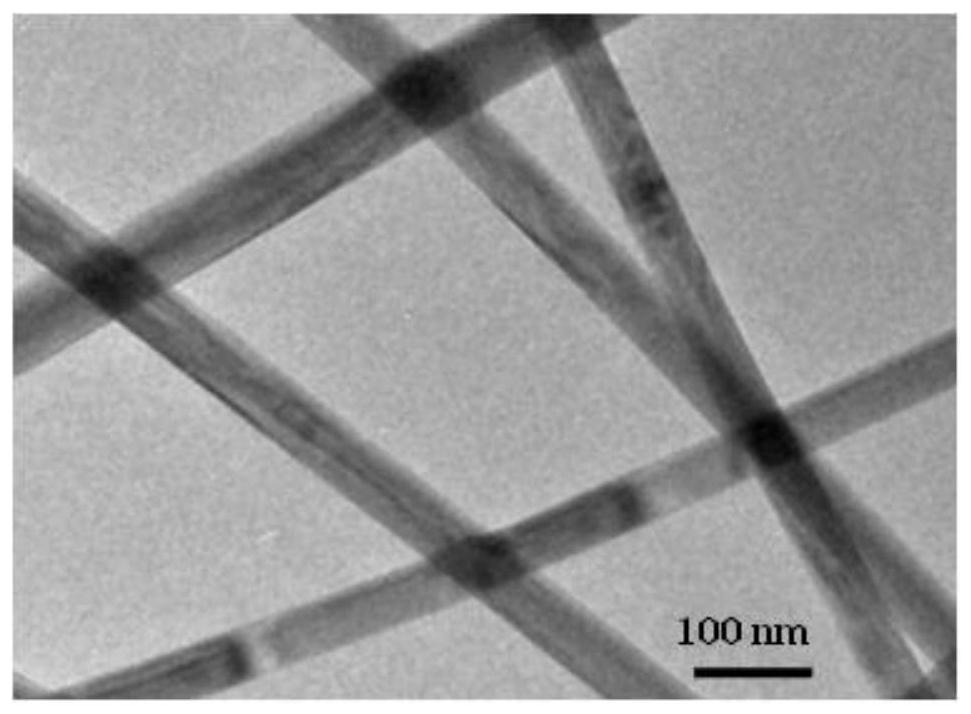

[0037] figure 1 and figure 2 It is the X-ray diffraction collection of patterns and the transmission electron microscope photo of the silver nanowire prepared in embodiment 1, by figure 1 It can be seen that the product is a metallic silver phase, and the crystallization is complete. figure 2 It can be seen that the product is silver nanowires, and the surface is clean without residue. After inspection, the obtained silver nanowires have a diameter of 45-55 nm and a length of 15-25 μm.

Embodiment 2

[0039] Weigh 2g of silver bromide and add it to 200mL (0.094g / mL) of trisodium citrate aqueous solution, and ultrasonically obtain a uniform silver bromide dispersion;

[0040] The dispersion liquid was added to the lining of the reaction kettle, and reacted at 140° C. for 200 minutes to obtain a mixture; and the mixture was centrifuged to obtain the silver nanowires.

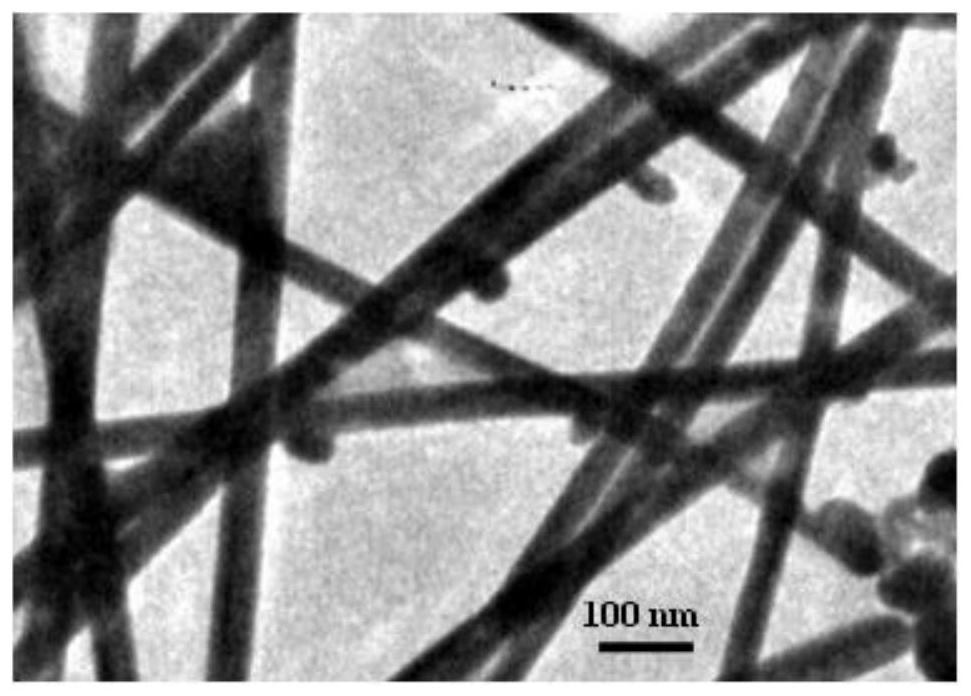

[0041] image 3 It is the transmission electron micrograph of the silver nanowire prepared in embodiment 2, by image 3 It can be seen that the surface of the silver wire is clean without residue, and there are a few granular silver. After inspection, the obtained silver nanowires have a diameter of 45-55 nm and a length of 15-25 μm.

Embodiment 3

[0043] Weigh 1g of silver iodide and add it to 100mL (0.075g / mL) of trisodium citrate aqueous solution, and ultrasonically obtain a uniform silver iodide dispersion;

[0044] The dispersion liquid was added to the lining of the reaction kettle, and reacted at 140° C. for 200 minutes to obtain a mixture; and the mixture was centrifuged to obtain the silver nanowires.

[0045] Figure 4 It is the transmission electron micrograph of the silver nanowire prepared in embodiment 3, by Figure 4 It can be seen that the surface of the silver wire is clean without residue, and there are a few granular silver. After inspection, the obtained silver nanowires have a diameter of 45-55 nm and a length of 15-25 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com