Platinum/carbon aerogel catalyst used for fuel cells and preparation method thereof

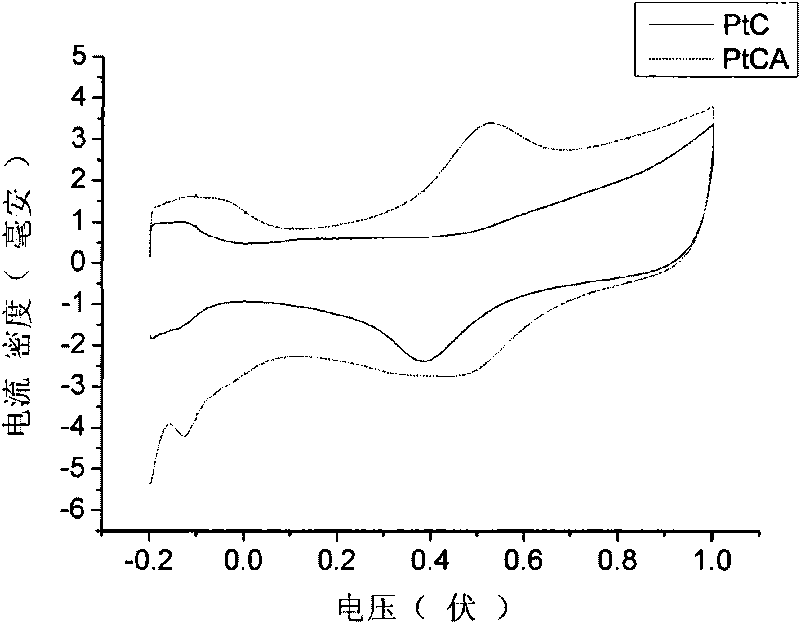

A carbon aerogel and fuel cell technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of large catalyst particles, cumbersome operation steps, and long preparation time, and achieve uniform distribution, simple preparation process, and short preparation time The effect of shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] ① Add resorcinol, formaldehyde, and catalyst anhydrous sodium carbonate with a molar ratio of 1:2:200 into the secondary deionized water, mix and stir evenly, place in a closed container, and stand at 85°C for 7 days. Obtain organic airgel; Resorcinol and formaldehyde weight account for 20% of total solution weight;

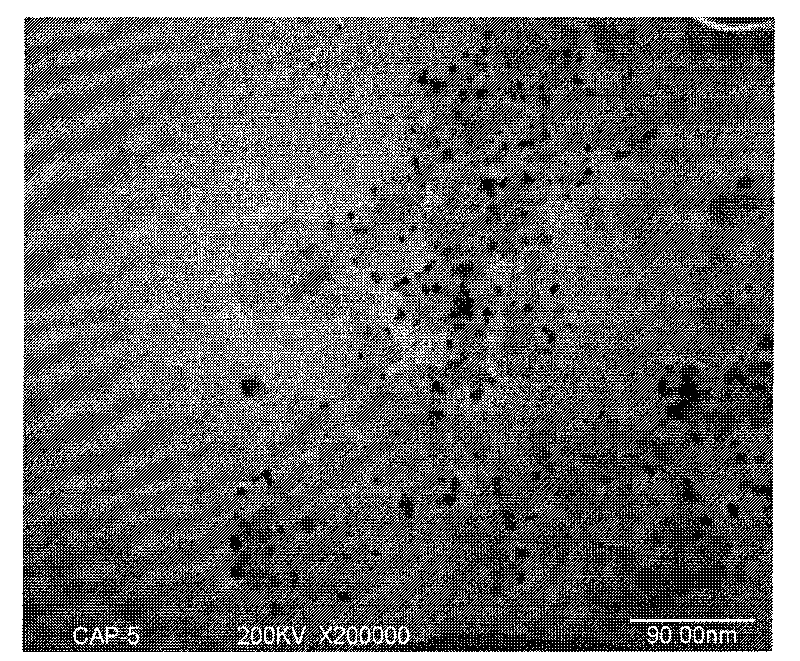

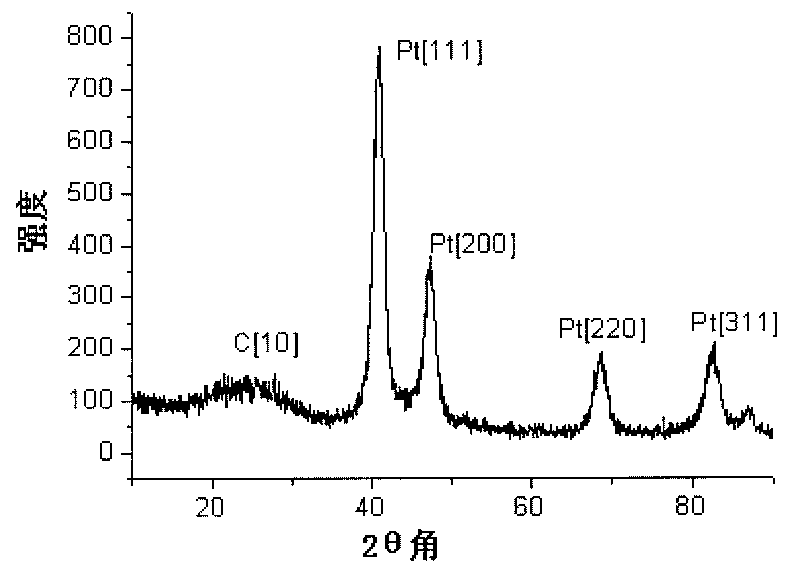

[0034] ②Put the organic airgel obtained in step ① into an acetic acid solution with a volume fraction of 2%. The acetic acid solution can be immersed in the organic aerogel. Place it for 3 days, take it out, and place it in acetone (analytical pure) for 3 days. Acetone is replaced once a day, taken out, placed in the air to dry, ground into powder (particle size is 20-30nm), to obtain carbon airgel powder; its physical parameters are: specific surface area 1000m 2 / g, pore size distribution 2-50nm, density distribution 1.0g / cm 3 , Conductivity -40s / cm.

[0035] ③The carbon airgel powder prepared in step ② is slowly heated to 250°C for 2 hours in a nitrog...

Embodiment 2

[0043] Preparation method of carbon airgel:

[0044] ① Add resorcinol, formaldehyde, and catalyst ammonium bicarbonate with a molar ratio of 1:1:100 into secondary deionized water, mix and stir evenly, place in an airtight container, and stand at 90°C for 4 days to obtain Organic airgel; the weight of resorcinol and formaldehyde accounts for 30% of the total solution weight;

[0045] ②Put the organic aerogel obtained in step ① into an acetic acid solution with a volume fraction of 1%, place it for 2 days, take it out, place it in an acetone solution for 4 days, replace the acetone once a day, take it out, dry it in the air, and grind it into powder to obtain carbon airgel powder; its physical parameters are: specific surface area 500m 2 / g, pore size distribution 2-50nm, density distribution 0.4g / cm 3 , Conductivity -40s / cm.

[0046] ③Use the carbon airgel powder prepared in step ② to slowly heat up to 300°C for 1 hour in an atmosphere of helium protection gas, maintain it ...

Embodiment 3

[0051] Preparation method of carbon airgel:

[0052] ① Add resorcinol, formaldehyde, and catalyst ammonium carbonate with a molar ratio of 1:1.5:1500 into secondary deionized water, mix and stir evenly, place in a closed container, and stand at 80°C for 3 days to obtain organic Airgel; resorcinol and formaldehyde weight account for 60% of the total solution weight;

[0053] ②Put the organic airgel obtained in step ① into the acetic acid solution with a volume fraction of 3%, place it for 1 day, take it out, place it in the acetone solution for 2 days, replace the acetone once a day, take it out, dry it in the air, and grind it into powder to obtain carbon airgel powder; its physical parameters are: specific surface area 1500m 2 / g, pore size distribution 2-50nm, density distribution 0.6g / cm 3 , Conductivity -40s / cm.

[0054] ③Use the carbon airgel powder prepared in step ② to slowly heat up to 200°C for 1.5 hours in an argon protective gas atmosphere and maintain it for 2.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size distribution | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com