Preparation method of graphene film

A graphene film and graphene technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve problems such as difficult human control, affecting film quality, inconsistent graphene growth mode, etc., to reduce the impact , Improve the effect of quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

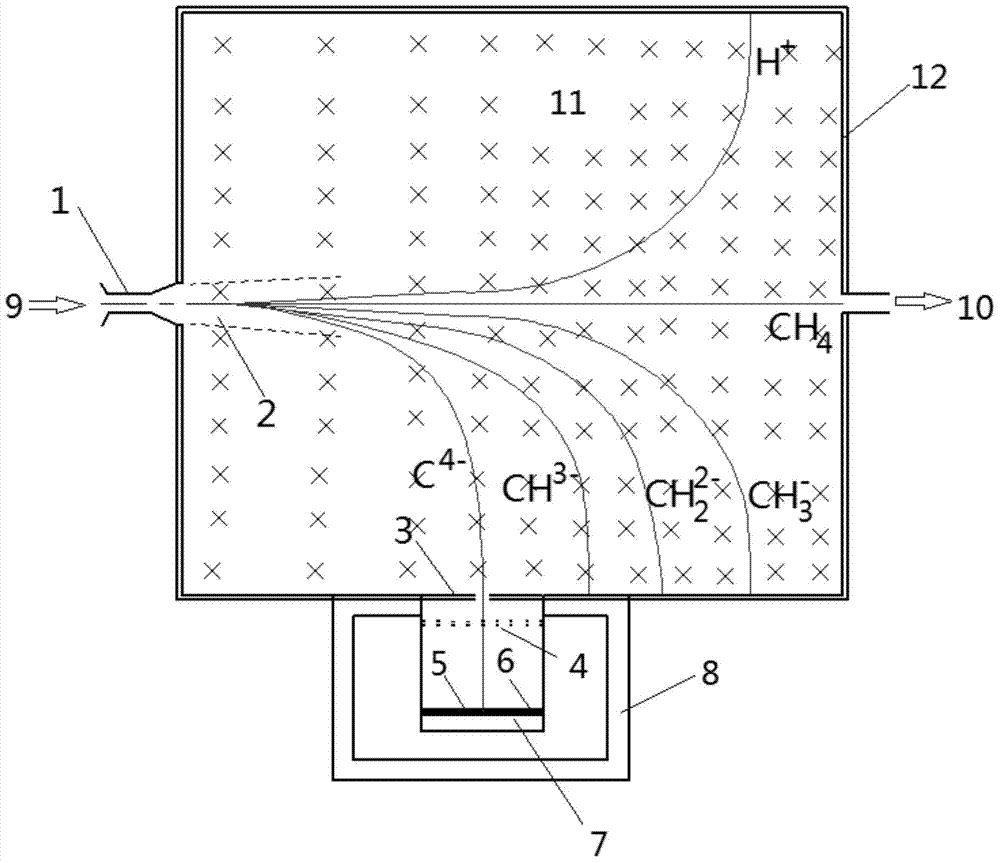

[0043] see figure 1 , the preparation method of the present invention utilizes a preparation equipment to prepare graphene thin film 4, and described preparation equipment comprises plasma chamber 12, and plasma chamber 12 is provided with plasma injection port 2, residual gas outlet 10, and plasma injection port 2 is provided with plasma The generator 1 and the carbon source 9 enter the plasma chamber 12 through the plasma injection port 2 after being processed by the plasma generator 1 , and a screening magnetic field 11 is formed in the plasma chamber 12 .

[0044] The plasma chamber 12 is provided with a baffle 3 , specifically, in this embodiment, the baffle 3 is placed at the bottom of the plasma chamber 12 . The plasma chamber 12 is also provided with a deposition chamber 8 outside, and a movable heating plate 7 is arranged in the deposition chamber 8, and a substrate (ie, a silicon substrate) 6 is arranged on the movable heating plate 7; above the silicon substrate 6, ...

Embodiment 2

[0055] This embodiment adopts the same method as Embodiment 1, and the difference from Embodiment 1 is that the screening magnetic field strength is 20 Oz, and the movement radius of carbon ions is 3.1 cm at this time. Adjust the distance between the slit on the baffle and the plasma entrance to 3.6cm, carbon ions can enter the accelerating electric field through the upper plate of the accelerating electric field, while other negative ions cannot enter the accelerating electric field.

Embodiment 3

[0057] This embodiment adopts the same method as Embodiment 1, and the difference from Embodiment 1 is that the screening magnetic field strength is 5 Oz, and the movement radius of carbon ions is 12.4 cm at this time. Adjust the distance between the slit on the baffle and the plasma entrance to 12.4cm, carbon ions can enter the accelerating electric field through the upper plate of the accelerating electric field, while other negative ions cannot enter the accelerating electric field.

[0058] In summary, the preparation method of the graphene film proposed by the present invention enhances the deposition of carbon ions to the surface of the substrate through the electromagnetic field, and can effectively separate the carbon ions from other ions by controlling the screening magnetic field at the same time, reducing the impact of other ions on the graphene film. quality impact. By controlling the accelerating electric field, the speed at which carbon ions bombard the substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com