A method of controlling mycelium growth form

A technology of mycelium and morphology, applied in the field of bioengineering, can solve the problems of inability to effectively control the fermentation morphology of filamentous fungi, harsh process conditions, complicated operation methods, etc., and is suitable for large-scale fermentation, simple operation, and easy to scale up. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

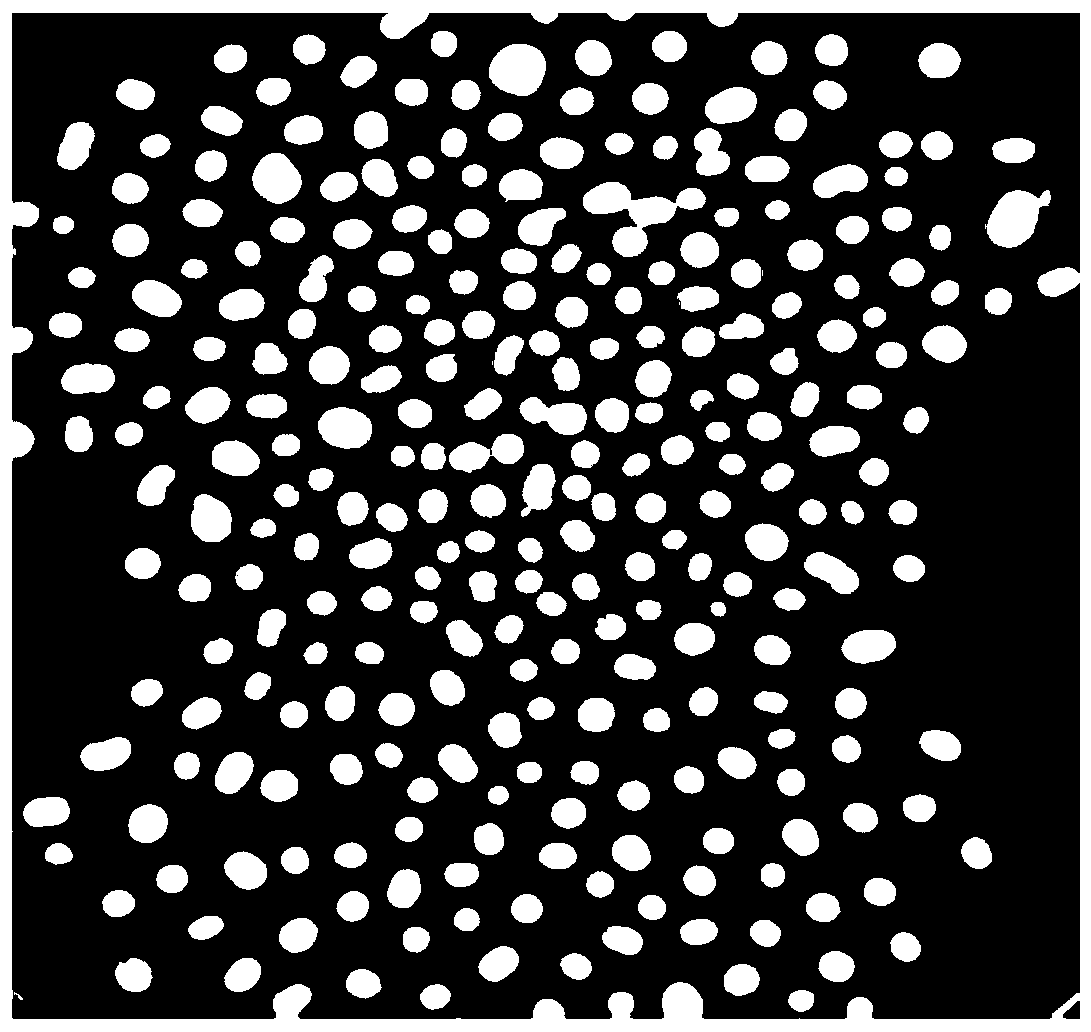

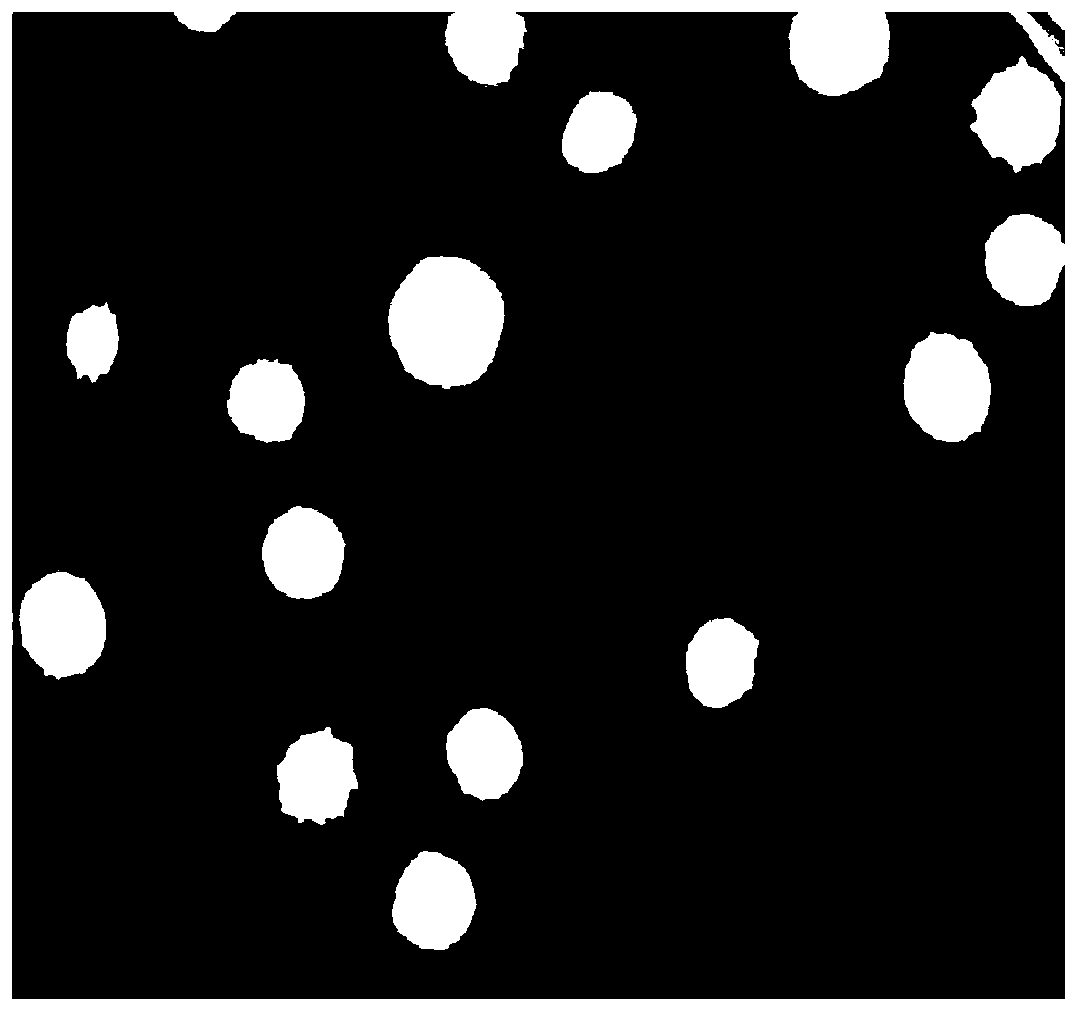

Image

Examples

Embodiment 1

[0054] This embodiment illustrates the method of utilizing farnesol to control mycelium morphology:

[0055] (1) Preparation of medium: basal medium includes, glucose 20g / L, (NH 4 ) 2 SO 4 5g / L, KH 2 PO 4 4g / L, MgSO 4 7H2O 2g / L, FeSO 4 7H2O 0.1g / L, CaCl 2 2H 2 O 0.5g / L, glucose is sterilized separately, sterilized at 115°C for 30min;

[0056] (2) Seed culture: add 1 mL of Rhizopus niger spore suspension to the medium described in step (1), cultivate it for 20 hours at 28° C. and 160 rpm, and obtain the seed liquid after the culture is homogenized;

[0057] (3) Farnesol is dissolved in ethanol at a concentration of 200 mM, and 0.22 μm membrane filter is sterilized to prepare a farnesol solution;

[0058] (4) At the 0th hour of the whole culture process, add farnesol solution until the concentration in the fermentation broth reaches 200 μM, and the culture medium without adding farnesol is used as a control;

[0059] (5) Fermentation culture: the seed liquid was inse...

Embodiment 2

[0062] This embodiment illustrates a method utilizing farnesol to control mycelium morphology:

[0063] (1) The preparation of the medium: the basic medium includes, sucrose 50g / L, urea 10g / L, KH 2 PO 4 1g / L, MgSO 4 ·7H 2 O 1g / L, CaCl 2 2H 2 O 0.05g / L, glucose is sterilized separately, sterilized at 115°C for 30min;

[0064] (2) Seed culture: add 1 mL of Aspergillus niger spore suspension to the medium described in step (1), cultivate at 30° C. and 150 rpm for 36 hours, and homogenize the culture to become the seed liquid;

[0065] (3) Farnesol is dissolved in ethanol at a concentration of 200 mM, and 0.22 μm membrane filter is sterilized to prepare a farnesol solution;

[0066] (4) At the 0th hour of the whole culture process, add farnesol solution until the concentration in the fermentation broth reaches 150 μM, and the culture medium without adding farnesol is used as a control, and the pH is adjusted to 6.0 with HCl;

[0067] (5) Fermentation culture: the seed liqui...

Embodiment 3

[0070] This example illustrates a method of using farnesol to control mycelium growth morphology to carry out lovastatin fermentation production:

[0071] (1) Preparation of medium: basal medium includes, glycerol 5%, glucose 10g / L, soybean peptone 2g / L, (NH 4 ) 2 SO 4 2g / L, KH 2 PO 4 1.5g / L, MgSO 4 ·7H 2 O 1g / L, FeSO 4 ·7H 2 O0.05g / L, CaCl 2 2H 2 O0.05g / L, glucose is sterilized separately, sterilized at 115°C for 30min;

[0072] (2) Seed culture: add 1 mL of Monascus spore suspension to the medium described in step (1), cultivate at 30° C. and 200 rpm for 48 hours, and homogenize the culture to become the seed liquid;

[0073] (3) Farnesol is dissolved in ethanol at a concentration of 200 mM, and 0.22 μm membrane filter is sterilized to prepare a farnesol solution;

[0074] (4) At the 48th hour of the entire culture process, add the farnesol solution in step (3) until the concentration in the fermentation broth reaches 500 μM, and the culture medium without addin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com