Cooling system of high concentration solar generating battery assembly

A solar cell and high-power concentrating technology, which is applied in the field of cooling systems, can solve problems such as heat dissipation of high-power concentrating solar cell components, and achieve the effects of lowering temperature, prolonging service life, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

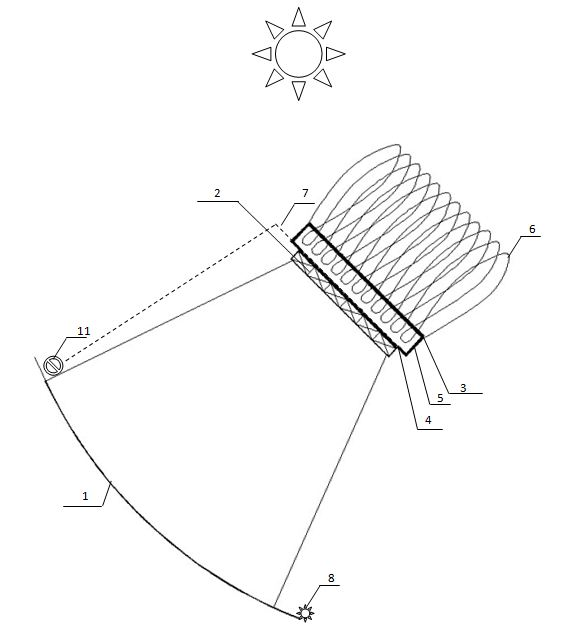

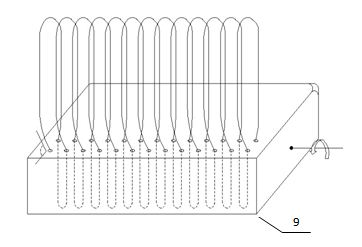

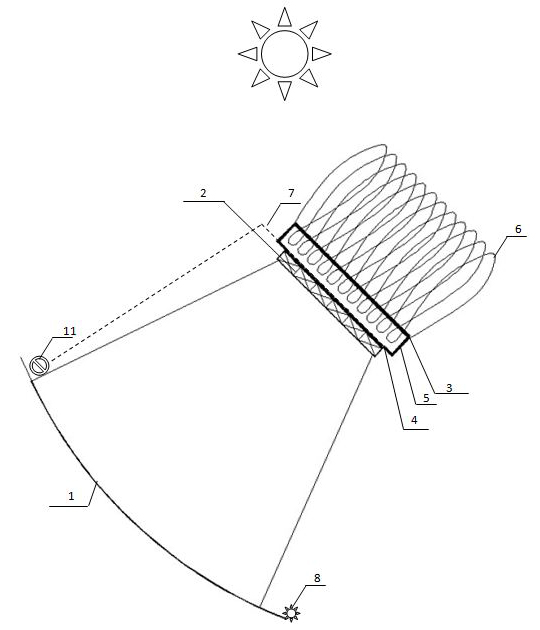

[0020] figure 1 Among them, it includes an oscillating flow heat pipe radiator 3 integrally packaged with the solar cell module 2, the side of the oscillating flow heat pipe radiator 3 close to the solar cell module 2 is an evaporation section 5, and a U-shaped microgroove 9 is etched inside, and the evaporation section 5 and at least one temperature sensor 7 is arranged between the solar cell module 2; the other side of the oscillating flow heat pipe radiator 3 is a condensation section 6, and the condensation section 6 is composed of a plurality of capillary tubes 10 without a housing, and the capillary tubes 10 and U-shaped The microgrooves 9 are docked to form an interconnected loop; the temperature sensor 7 measures the temperature of the solar cell module 2 in real time, and sends the signal to the mechanical controller 11. If the temperature exce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com