Heat phonomotor capable of utilizing multi-temperature position heat power supply drive

A thermoacoustic engine, heat source technology, applied in the direction of machines/engines, mechanisms that generate mechanical power, mechanical equipment, etc., can solve problems such as underutilization of heat sources, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

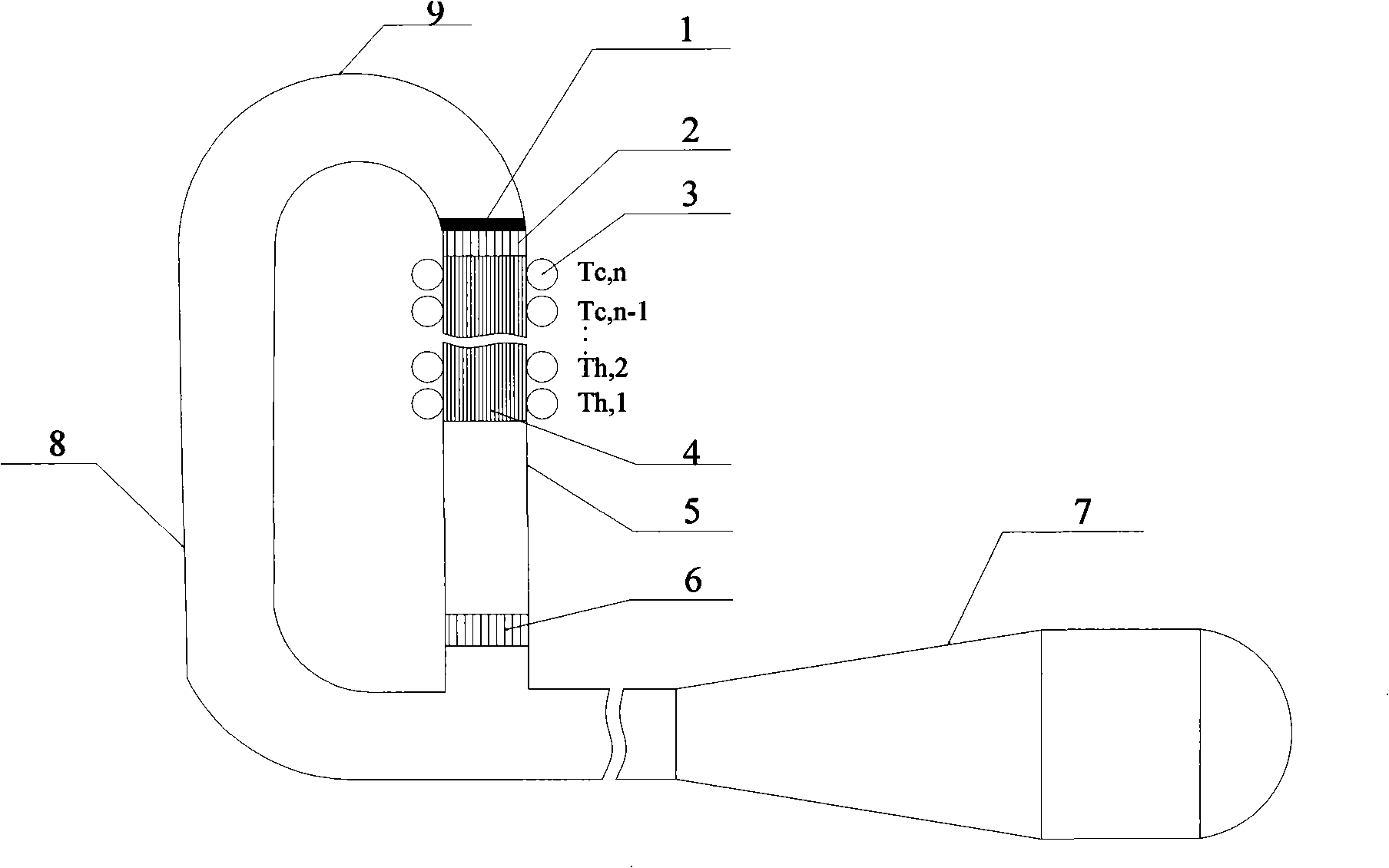

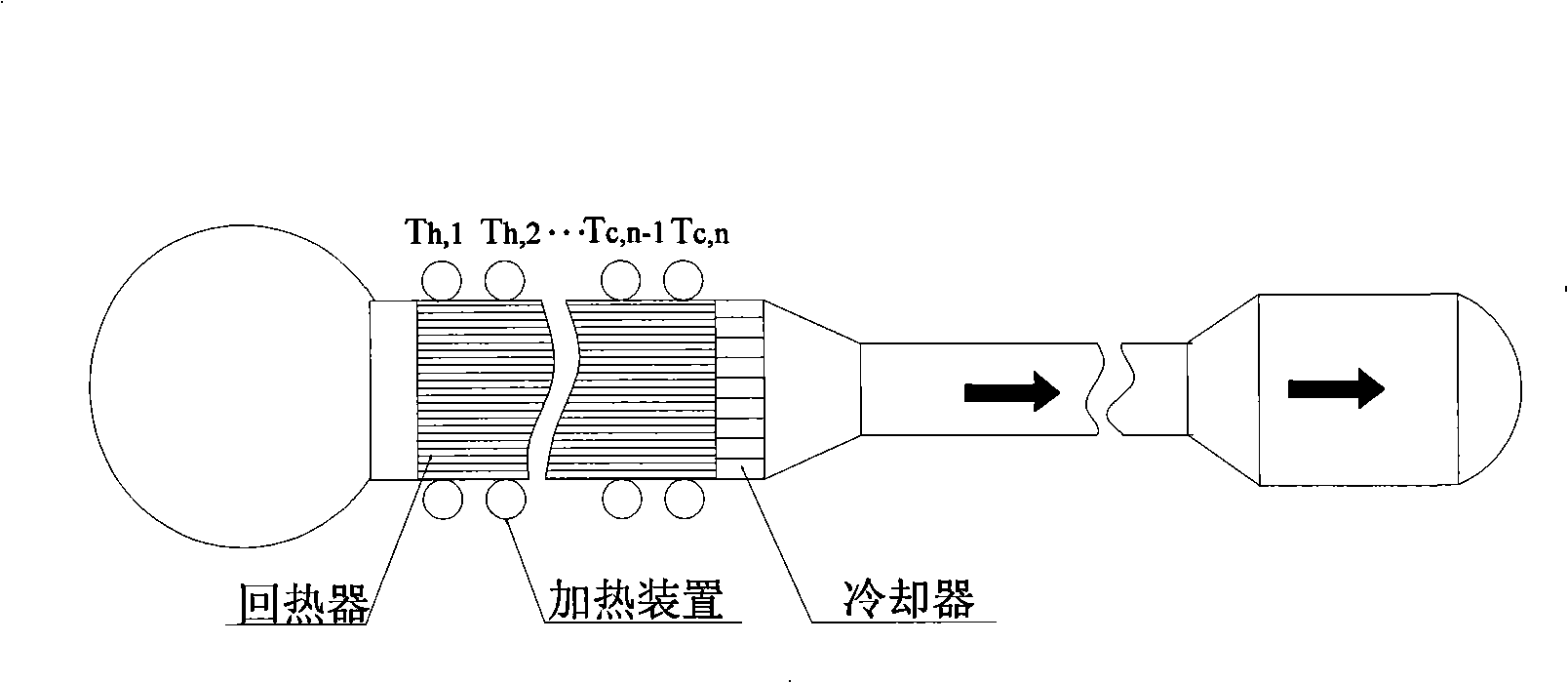

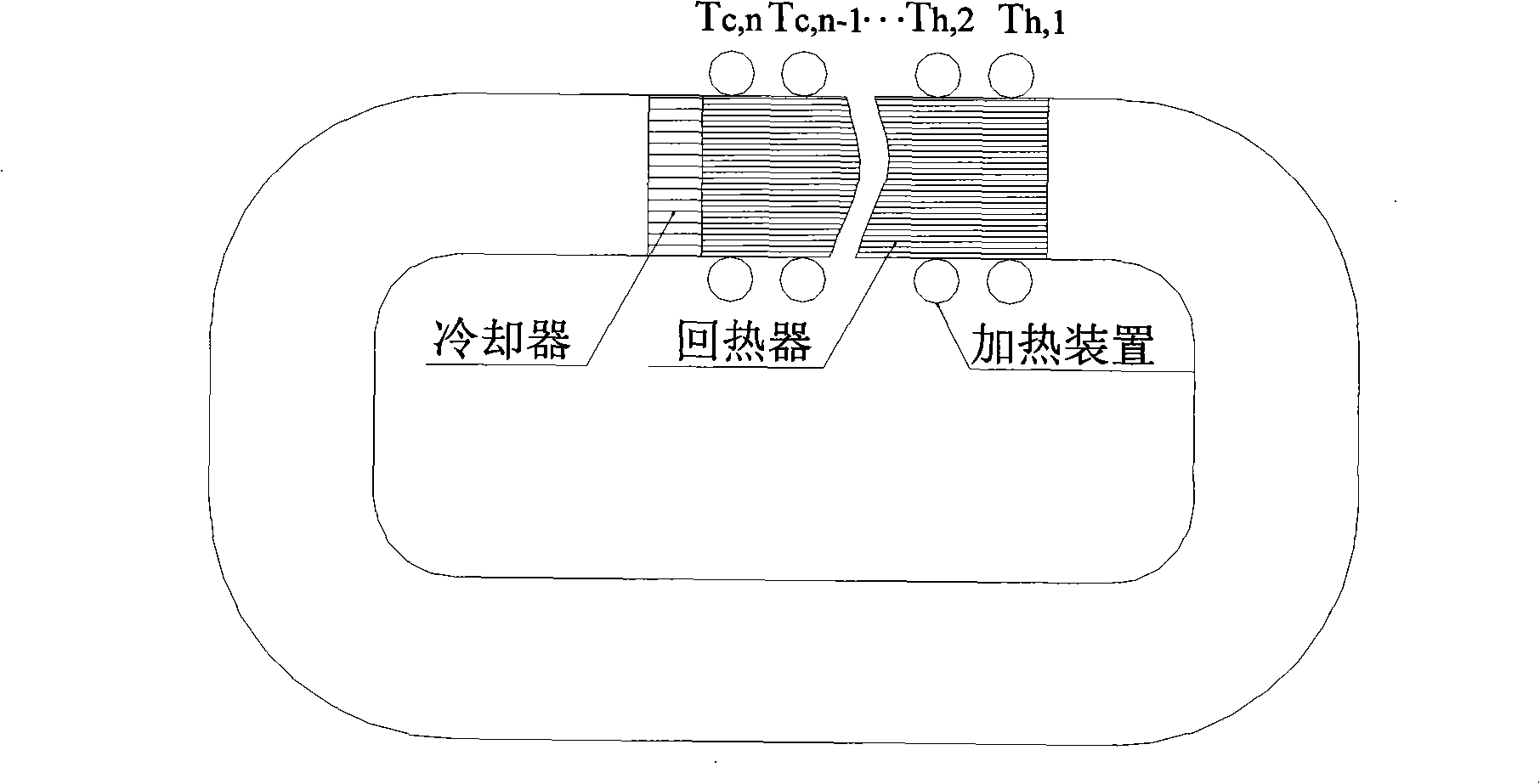

[0016] The regenerator of the existing thermoacoustic engine is driven by a single-temperature heat source, and the thermoacoustic engine that can be driven by multi-temperature heat sources is formed by improving the regenerator and heating device on the original thermoacoustic engine. The present invention proposes to divide the regenerator 4 of the thermoacoustic engine into n units from the high temperature end to the room temperature end, and provide each unit with a heat source T from high to low in turn. h,1 ,T h,2 ,...,T c,n-1 ,T c,n . The filler of the regenerator 4 is made of stainless steel wire mesh, and the shell is made of a rigid tube with poor heat transfer performance. Its function is to seal the high-pressure gas and provide rigid support for the working fluid. Arrange the working temperature on the shell in turn at T h,1 ,T h,2 ,...,T c,n-1 ,T c,n The heating device 3 is made as a high-temperature heat exchanger, and the high-temperature heat exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com