Oscillating flow micromixer

A micro-mixer, oscillating flow technology, applied in the direction of shaking/oscillating/vibrating mixers, mixers, chemical instruments and methods, etc., can solve the problems of smaller liquid contact area, reduced mixing effect, weakened mixing effect, etc. Enhanced mixing, low processing cost, good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

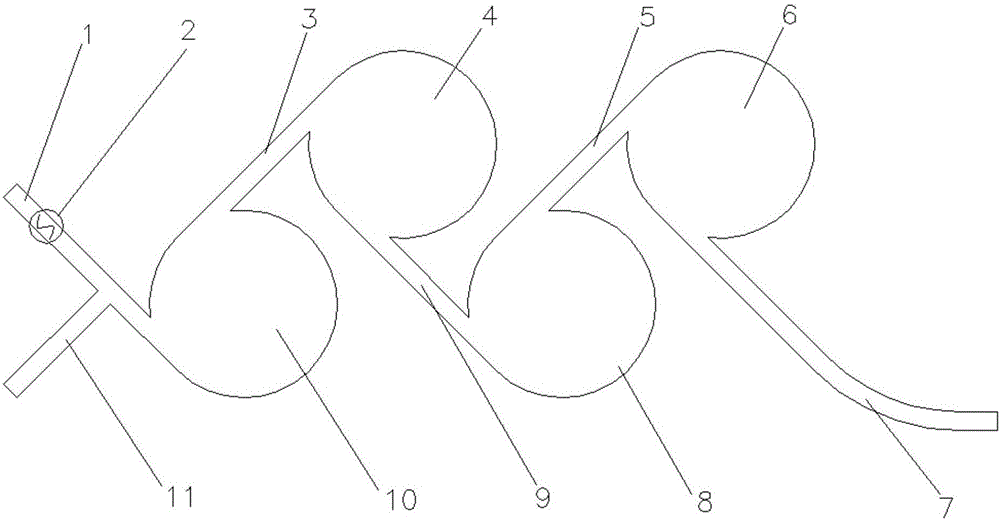

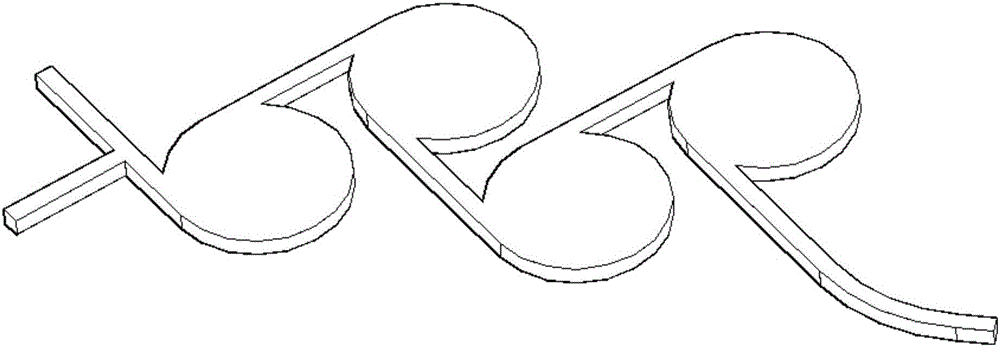

[0035] combine figure 1 , figure 2 , an oscillating flow micromixer with two inlet channels, comprising a first inlet channel 1, a second inlet channel 11, an oscillator 2, a first circular chamber 10, a first connecting channel 3, a second circular chamber 4. The second connecting channel 9, the third circular chamber 8, the third connecting channel 5, the fourth circular chamber 6, and the outlet channel 7;

[0036] The first inlet channel 1 and the second inlet channel 11 are used as two inlets of liquid flowing into the first circular chamber 10, the first inlet channel 1 is tangent to the outer circle of the first chamber 10, and the second inlet channel 1 is tangent to the outer circle of the first chamber 10. The inlet channel 11 communicates with the first inlet channel 1; the first connecting channel 3 connects the first circular chamber 10 and the second circular chamber 4, and the first connecting channel 3 communicates with the first circular chamber 10 and the s...

Embodiment 2

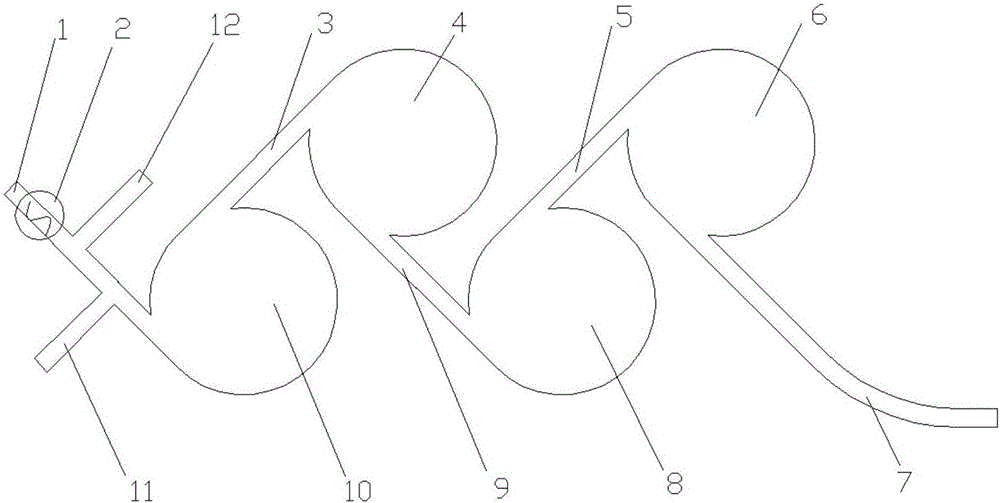

[0041] combine image 3 , an oscillating flow micro-mixer with three inlet channels, comprising a first inlet channel 1, a second inlet channel 11, a third inlet channel 12, an oscillator 2, a first circular chamber 10, a first connecting channel 3, The second circular chamber 4, the second connecting channel 9, the third circular chamber 8, the third connecting channel 5, the fourth circular chamber 6, and the outlet channel 7;

[0042] The third inlet channel 12 communicates with the first connecting channel, and the connection methods of the other inlet channels, the oscillator 2 , the circular chamber, the connecting channel and the outlet channel 7 are the same as those in the second embodiment.

[0043] combine Figure 4 , a graph of the relationship between the maximum viscosity of the liquid and the depth of the second chamber of the oscillator for an oscillatory flow micromixer of the present invention. The vertical axis on the left is the viscosity range that the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com