High-power LED (light emitting diode) heat radiator

An LED radiator, high-power technology, applied in lighting and heating equipment, cooling/heating devices for lighting devices, lighting devices, etc., can solve the problems of insufficient heat dissipation, difficult processing of LED radiators, and large size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

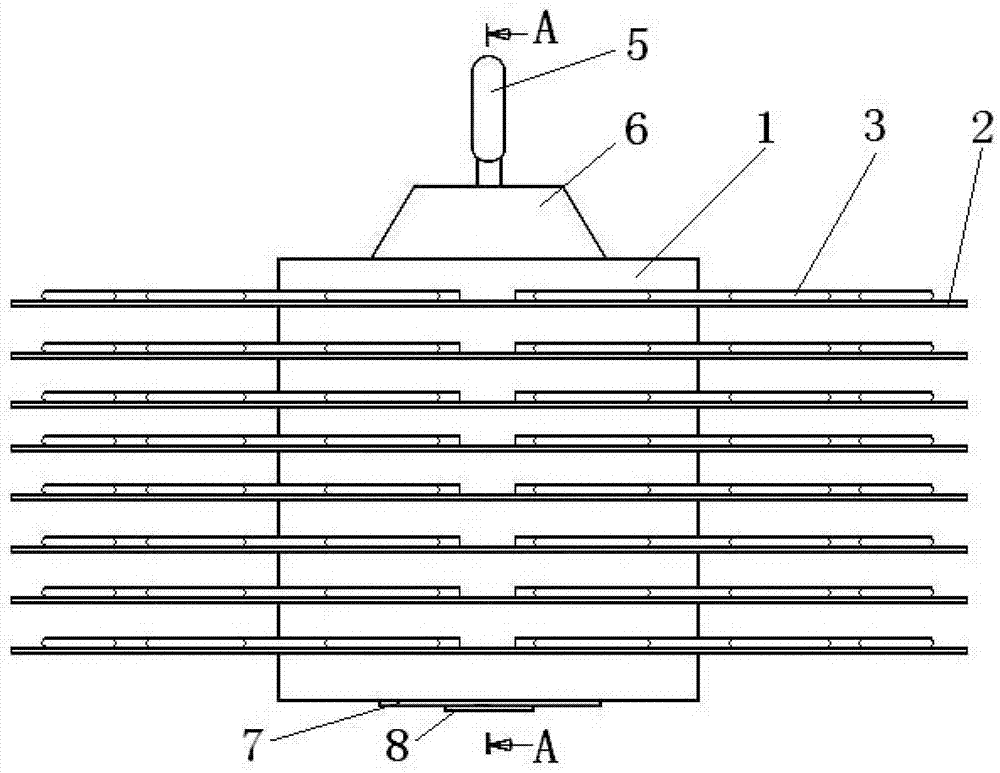

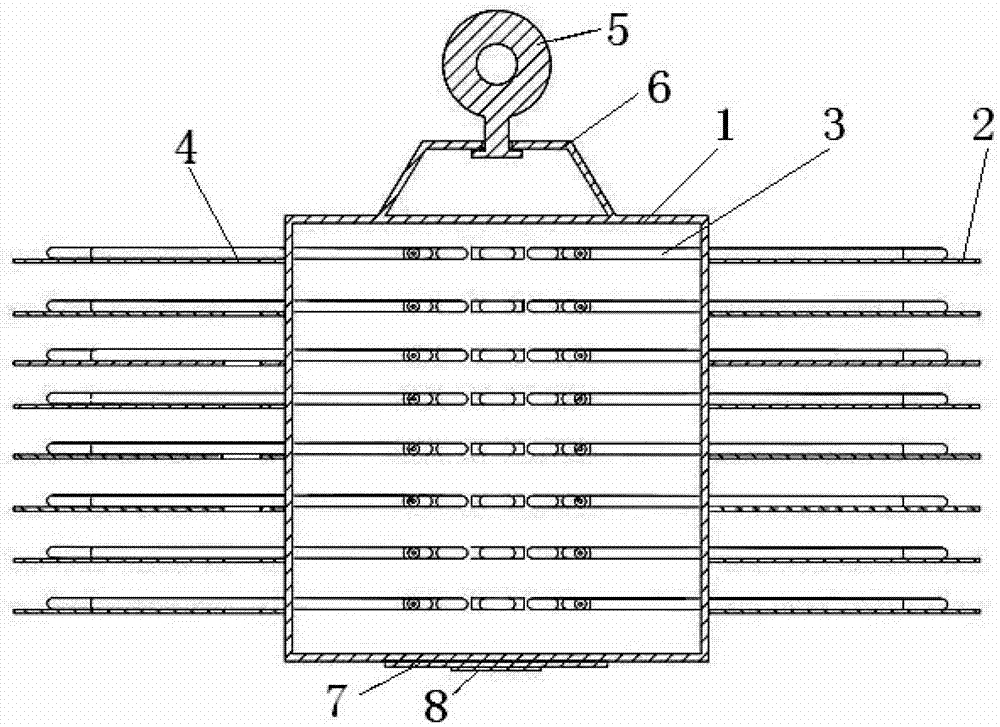

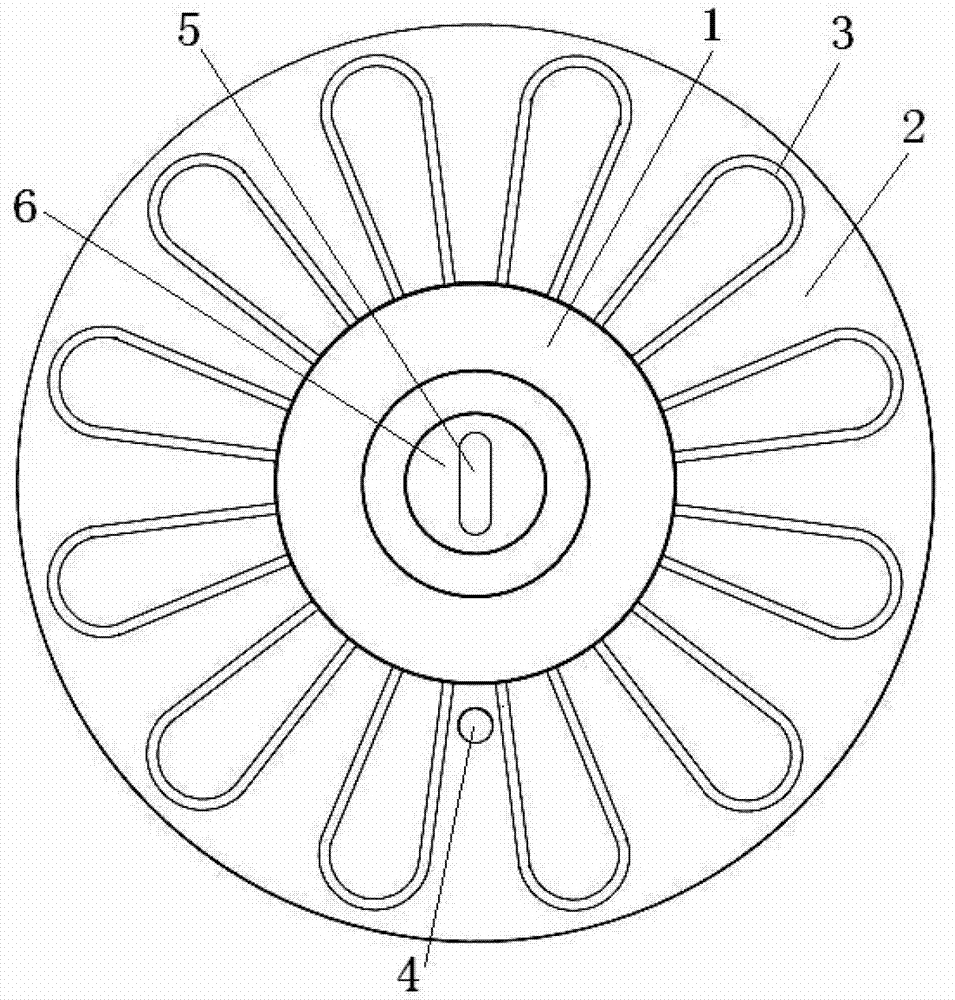

[0026] The structure of high-power LED radiator is as follows: figure 1 , image 3 and Figure 4 shown. 8 circular copper fins 2 are fixed horizontally on the outer wall of the cylindrical heat conduction cavity 1, and a divergent oscillating flow heat pipe 3 is coaxially welded on each fin 2, and the divergent oscillating flow heat pipe 3 is 24 An elbow petal-shaped single-circuit oscillating flow heat pipe, and a divergent oscillating flow heat pipe 3. The material of the capillary is copper tube. There is a wire hole 4 on the fin 2, and the wire holes 4 on all the fins 2 are on the same vertical line, and the LED power line passes therethrough. The heating section of the divergent oscillating flow heat pipe 3 passes through the outer wall of the heat conduction cavity 1 and is placed in the cavity of the heat conduction cavity 1, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com