Pulse Tube Refrigerator System Using Vehicle Vibration Energy

A technology of pulse tube refrigerator and vibration energy, which is applied in refrigerators, refrigeration and liquefaction, compressors, etc., can solve undiscovered problems and achieve the effects of low manufacturing cost, compact system structure, and long operating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

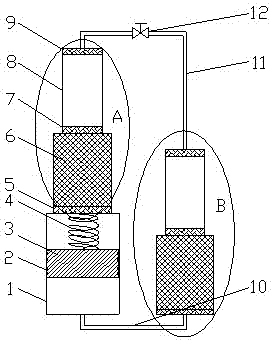

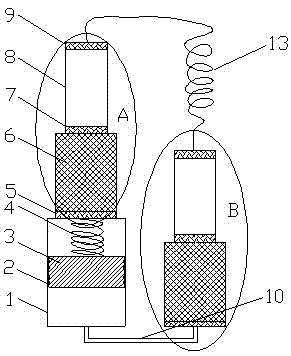

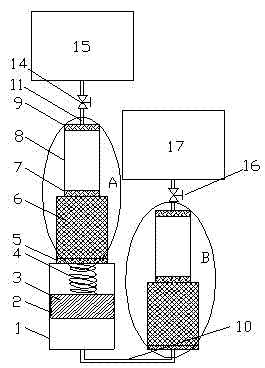

[0015] Such as figure 1 , 2 As shown, the pulse tube refrigerator utilizing automobile vibration energy includes a cylinder 1, a first pipeline 10, a second pipeline 11, a first pulse tube refrigerator A, a second pulse tube refrigerator B, and a phase modulation structure; the cylinder 1 , the first pulse tube refrigerator A, the phase modulation structure, the second pipeline 11, and the second pulse tube refrigerator B are connected in sequence, and the second pulse tube refrigerator B is connected to the cylinder 1 through the first pipeline 10, and the cylinder 1 A piston 3 is provided inside, a spring 4 is provided on the piston 3, and a groove 2 is provided around the piston 3. The first pulse tube refrigerator A and the second pulse tube refrigerator B include regenerator heat exchangers 5 connected in sequence , regenerator 6, pulse tube cold end heat exchanger 7, pulse tube 8, pulse tube hot end heat exchanger 9. The phase modulation structure is a needle valve 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com