Stirling pulse tube refrigerator connected with displacer

A pulse tube refrigerator and ejector technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of insufficient use of sound power, sound power loss, etc., to reduce sound power loss, reduce loss, Phased flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

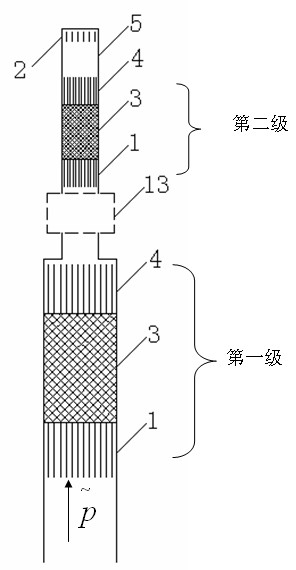

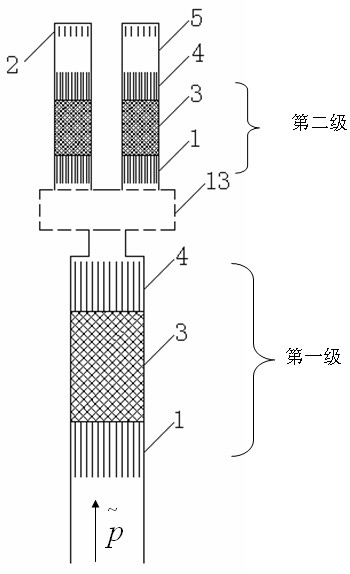

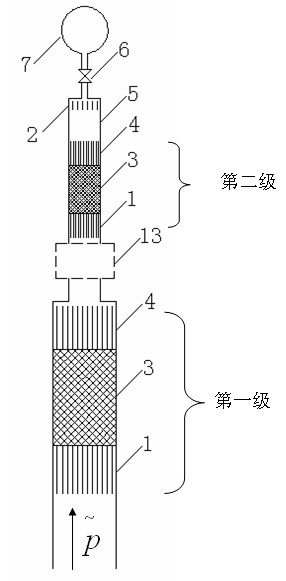

[0025] The Stirling type pulse tube refrigerator connected by the ejector is: the cold end of the first stage pulse tube refrigerator is connected to one end of the ejector, the other end of the ejector is connected to the room temperature end of the second stage pulse tube refrigerator, and the second stage One or more pulse tube refrigerators are connected in parallel, or one or more second stage pulse tube refrigerators are connected in series, and the first stage pulse tube refrigerator includes a room temperature end heat exchanger 1, a regenerator 3 and The cold end heat exchanger 4, the excluder is divided into free single-piston type, single-piston support type and double-piston support type, the free single-piston type has only the piston 10, the single-piston support type piston 10 is on the side of the elastic part 11, and the piston 10 A connecting rod 12 is arranged on the top and is connected with the elastic part 11. The double-piston support type piston 10 is on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com