Nonmagnetic low-vibration coaxial impulse pipe refrigerating machine

A pulse tube refrigerator, pulse tube technology, applied in refrigerators, gas circulation refrigerators, coolers, etc., can solve the problem that the airflow cannot be guaranteed to be smooth and uniform, the coaxial pulse tube refrigerator cannot be directly served, and the SQUID device measures millimetres. meaningless issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Further describe the present invention below in conjunction with accompanying drawing and embodiment example:

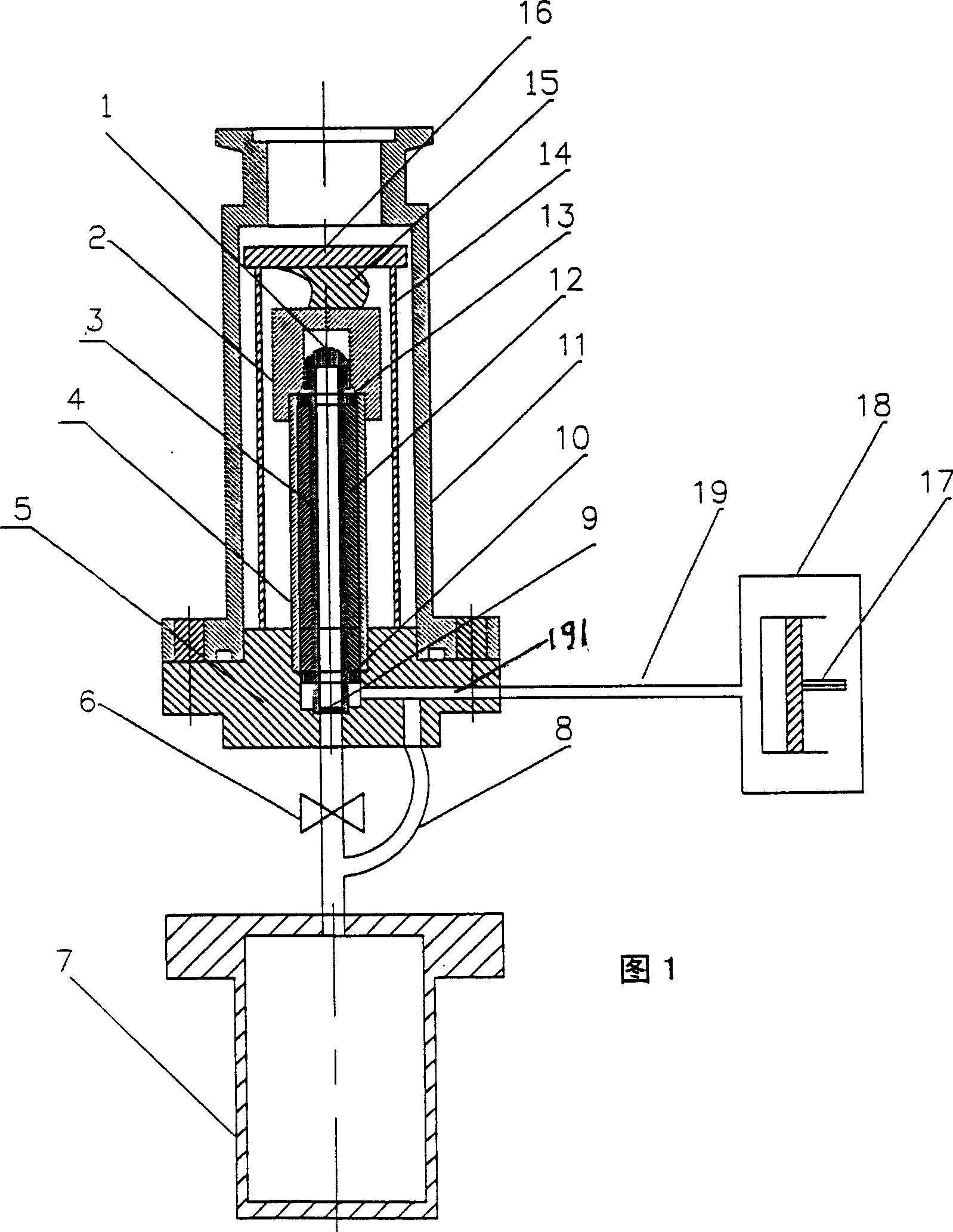

[0027] Fig. 1 shows the structure diagram of the non-magnetic and low-vibration coaxial pulse tube refrigerator of the present invention, as can be seen from the figure, the non-magnetic and low-vibration coaxial pulse tube refrigerator of the present invention, in the vacuum chamber, pulse tube 3 and regenerator 4 placed coaxially, filled with cold storage packing 12, the cold end of the pulse tube 3 is equipped with a pulse tube cold end deflector 1, the cold end of the regenerator is equipped with a regenerator cold end deflector 13, and the cold end of the refrigerator is equipped with The cold end heat exchanger 2, the hot end of the pulse tube is equipped with a hot end deflector 9 and a heat exchanger, and the pipeline between the heat exchanger and the gas storage 7 is provided with a throttling hole 6, and the compressor 17 is connected with the pulse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com