Pulse tube refrigerator

a refrigerator and pulse tube technology, applied in refrigeration machines, gas cycle refrigeration machines, lighting and heating apparatus, etc., can solve the problems of unsuitable actual use, rather small resonator tubes of former arts with inevitably large heat-driven pressure-wave generators, and unsuitable for small-size resonator tubes. , to achieve the effect of reducing vibration, reducing vibration, and free from vibration and nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

the Present Invention

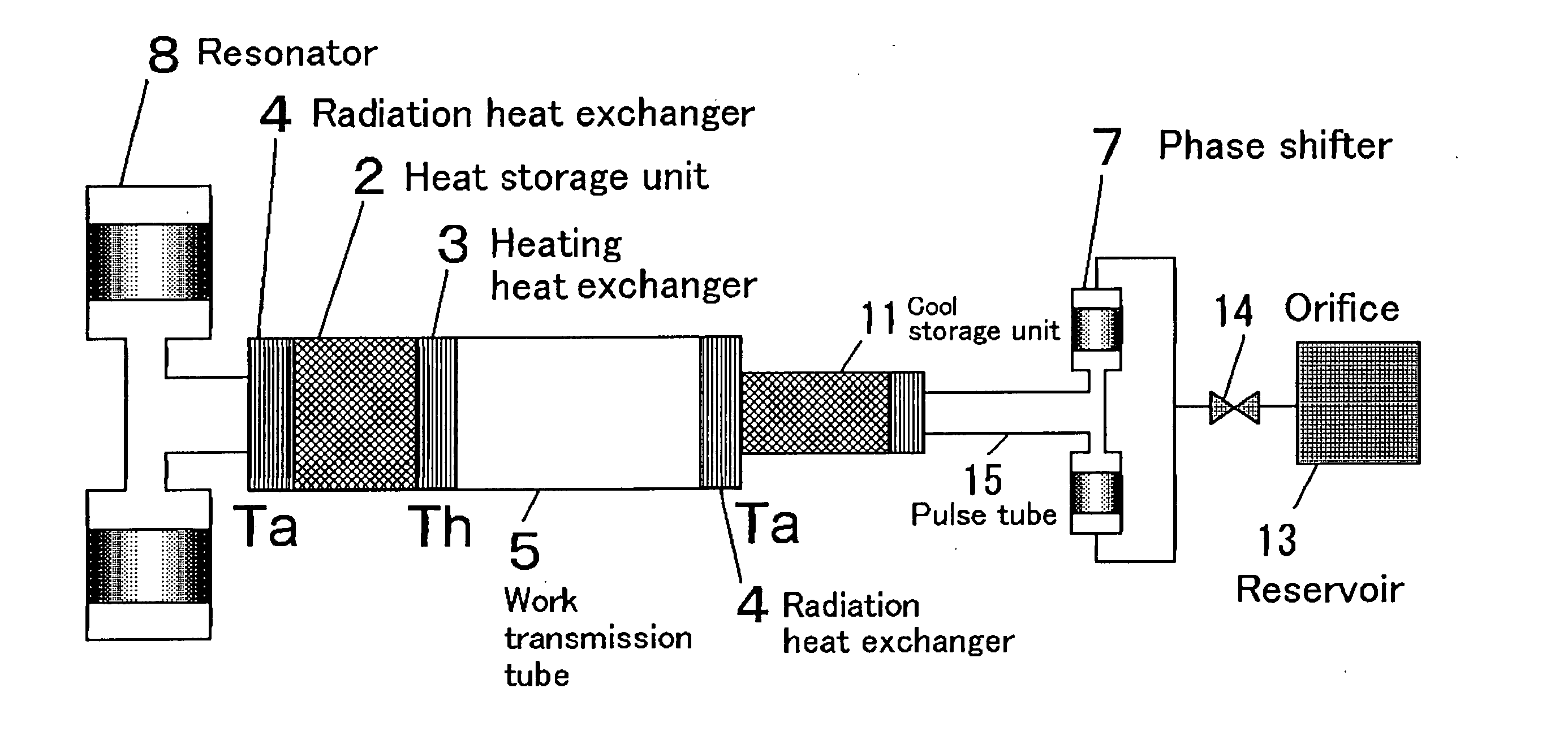

[0025] The first embodiment of the present invention is a pulse-tube refrigerator driven by a heat-driven pressure-wave generator equipped with a heat-driven tube, a phase shifter, and a return path.

[0026]FIG. 1 shows the schematic diagram for the pulse-tube refrigerator in the first embodiment of the present invention, wherein the pulse-tube refrigerator 1 is an orifice-type pulse-tube refrigerator that has a pulse tube, a cool storage unit connected to the low-temperature side of the pulse tube, a vibration generator connected to the high-temperature side of the cool storage unit, and a reservoir with the orifice connected to the high-temperature side of the pulse tube. Although omitted in the figure, these are the same as in FIG. 10. The heat storage unit 2 is a means to form an isothermal space that has a constant thermal slope, which is called “regenerator”. The heating heat exchanger 3 is a means to supply heat to the high-temperature side of the heat sto...

second embodiment

the Present Invention

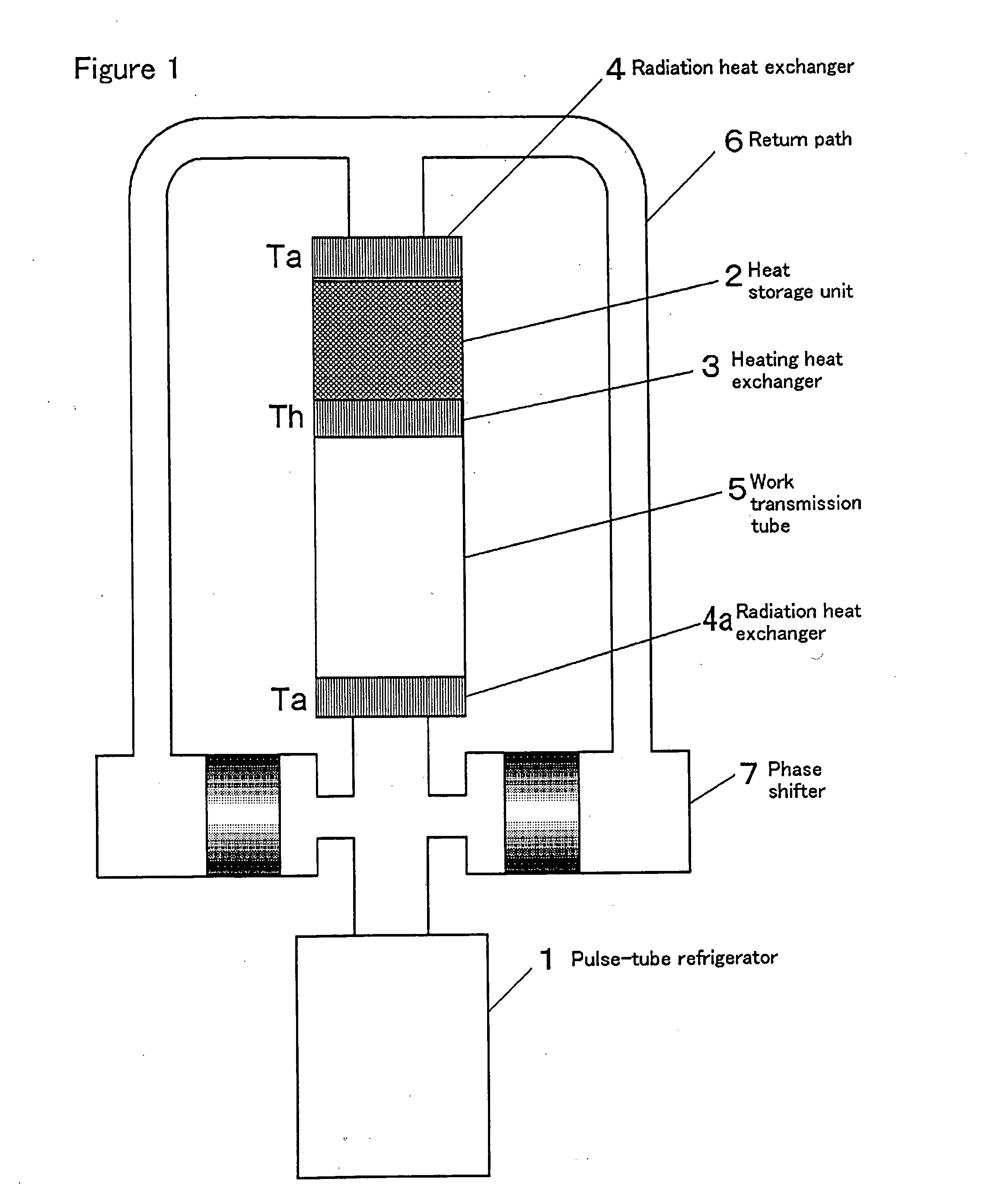

[0031] The second embodiment of the present invention is a pulse-tube refrigerator driven by a heat-driven pressure-wave generator that is equipped with a heat-driven tube, a resonator, a phase shifter, and a return path. The heat-driven pressure-wave generator is a Stirling-engine type. FIG. 2 shows a diagram of the pulse-tube refrigerator in the second embodiment of the present invention. In FIG. 2, the resonator 8 is a gas-spring resonator disposed at the work-output side of the heat-driven tube. The rest of the configuration is the same as in the first embodiment of the present invention. The basic configuration of this pulse-tube refrigerator is the same as the pulse-tube refrigerator in the former arts shown in FIG. 11. The significant difference is that the piston in the phase shifter can freely reciprocate. The heat-driven pressure-wave generator consists of the heat-driven tube, the return path 6, the phase shifter 7, and the resonator 8.

[0032] Here is...

third embodiment

the Present Invention

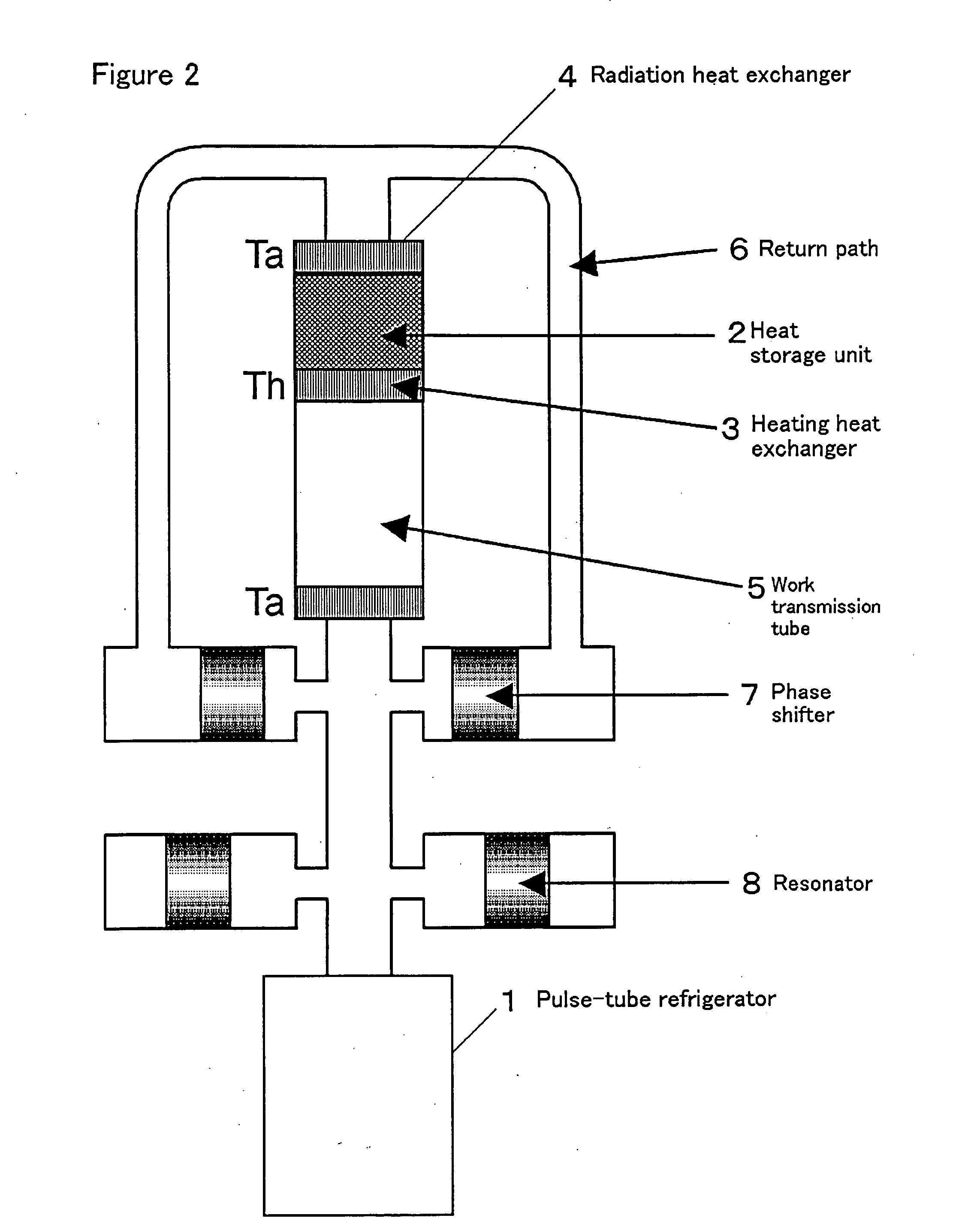

[0035] The third embodiment of the present invention is a pulse-tube refrigerator driven by a heat-driven pressure-wave generator that is equipped with a heat-driven tube and a resonator. The heat-driven pressure-wave generator is a standing-wave type. FIG. 3 is a schematic diagram that shows the configuration of the pulse-tube refrigerator in the third embodiment of the present invention. In FIG. 3, a heat storage unit 2 is a means to form an isothermal space that has a constant thermal slope. A heating heat exchanger 3 is a means to supply heat to the high-temperature side of the heat storage unit 2. A radiation heat exchanger 4 is a means to cool the low-temperature side of the heat storage unit 2 down to an ambient temperature. A high-temperature buffer 16 is a tube where the pressure wave is reflected to excite the standing wave in the heat-driven tube. The heat-driven tube consists of the heat storage unit 2, the heating heat exchanger 3, the radiation hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com