Clamping device

A clamping device and a technology for clamping tools, which are applied in the accessories of tool holders, turning equipment, socket/socket connections, etc., can solve the problems of harmful, damping cavity accumulation of chips, unbalance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

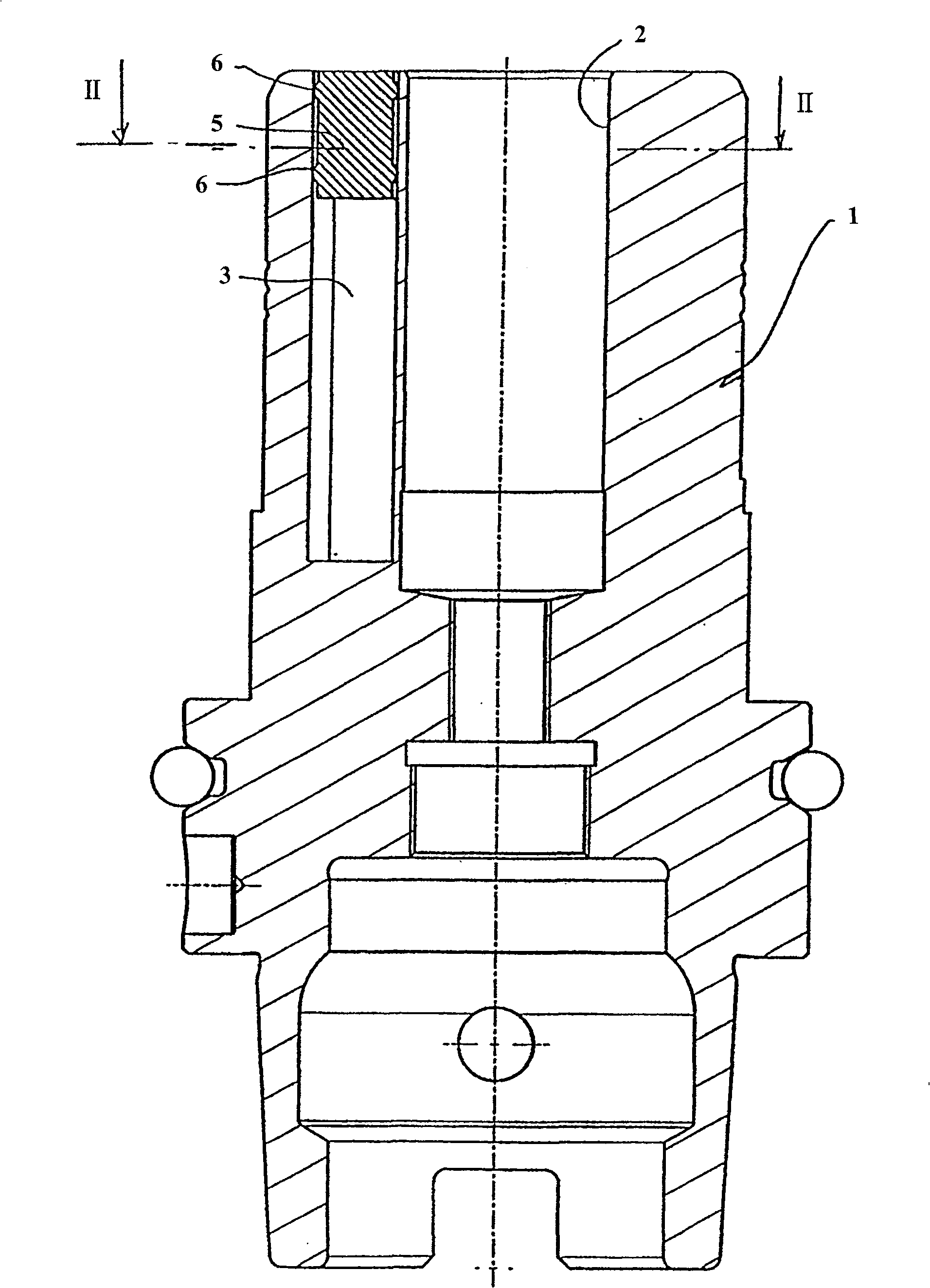

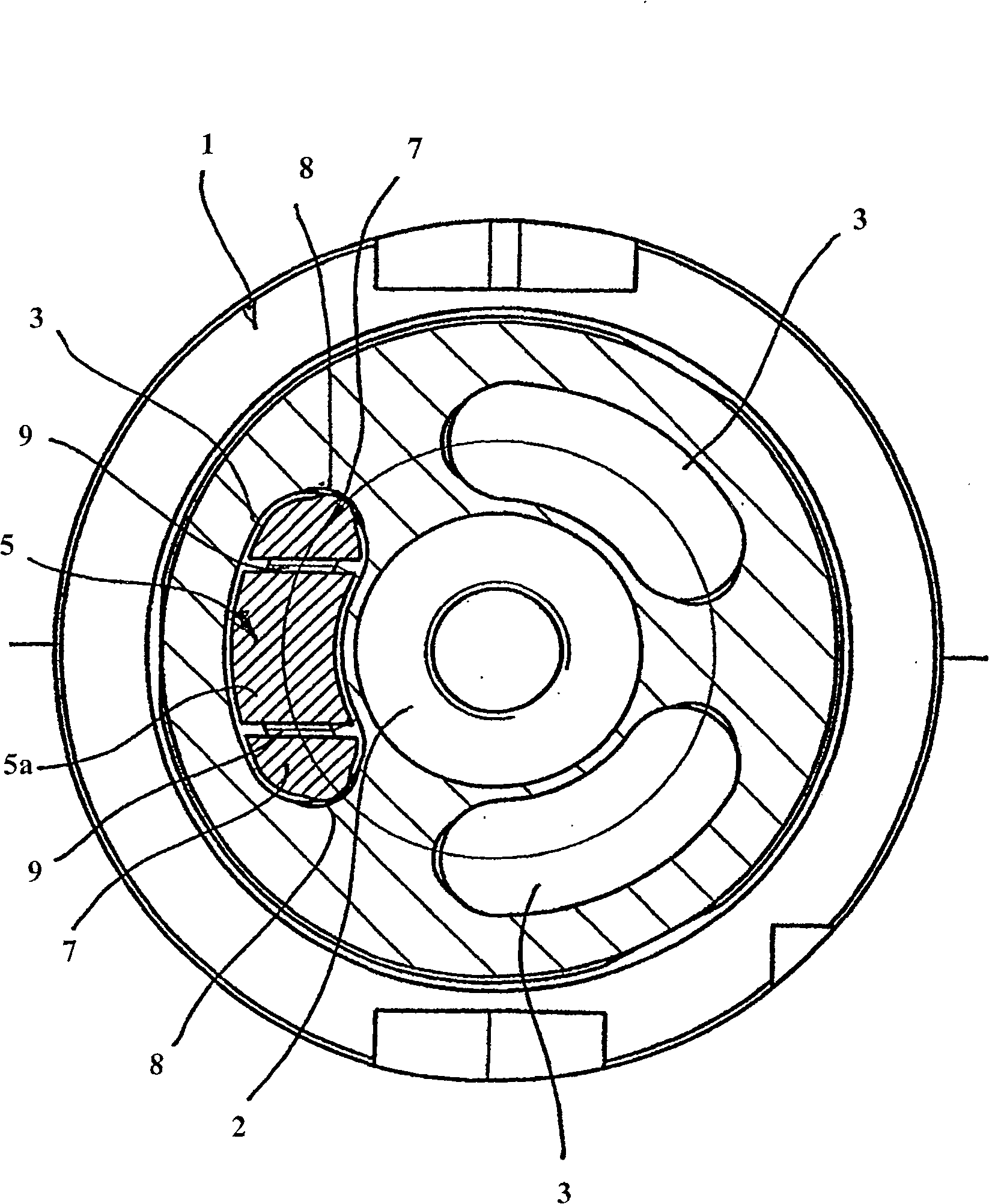

[0027] in figure 1 versus figure 2 Shown in is a longitudinal cross-sectional view of the first embodiment of the clamping device according to the aforementioned invention. The clamping device used to clamp the tool can be configured as a chuck, or it can be directly integrated into the work spindle of the machine tool, for example. . The chuck contains a chassis 1, which is made of a hard material such as steel. The chassis 1 has a central socket 2 in its end area. The socket 2 is used for the cylindrical tool holder of the tool W to be clamped, such as a drill tool holder. Or milling cutter arbor. The chassis 1 has a cutting position in its other end region according to a known method for clamping the tool holder to the work spindle of the machine tool.

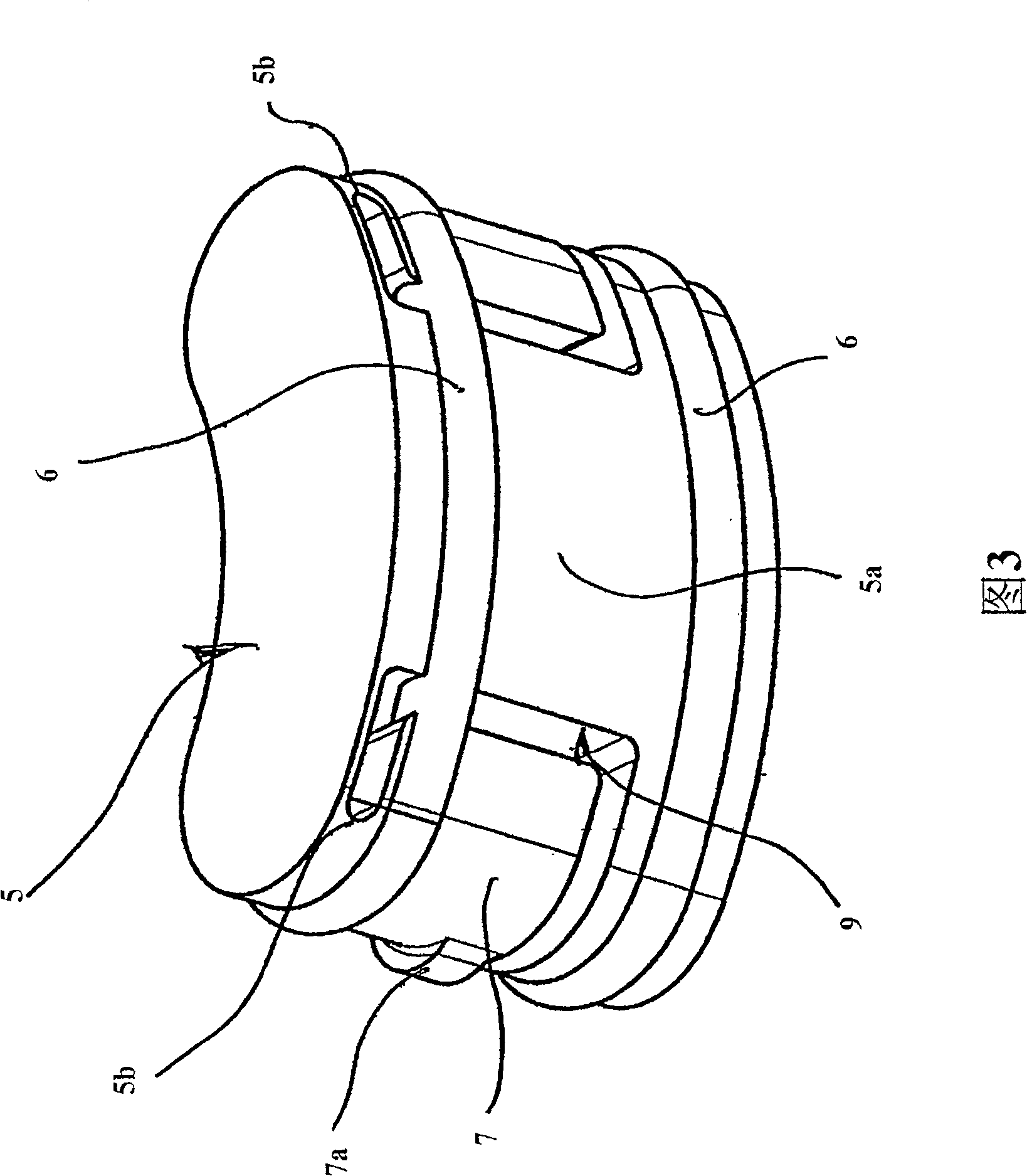

[0028] Three damping cavities 3 are evenly distributed around the socket 2 in the chassis 1. The damping cavity 3 opens toward the end surface of the chassis 1 on the tool side and forms an approximate kidney shape, wherein t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com