Double-layer wall cap anti-icing system with impact-gas film structure on front edge

An anti-icing system and cap technology, which are applied in jet propulsion devices, gas turbine devices, machines/engines, etc., can solve the problem that the internal heat exchange of the impact heat exchange structure is limited, the anti-icing measures outside the cap are not considered, and it is difficult to achieve anti-icing. effect and other issues, so as to meet the processing requirements, improve the implementability of processing, and enhance the anti-icing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

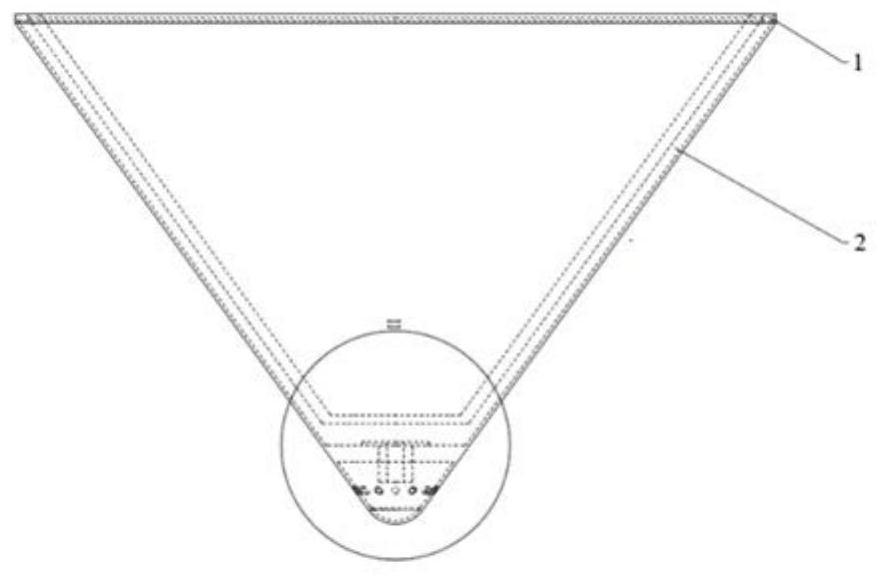

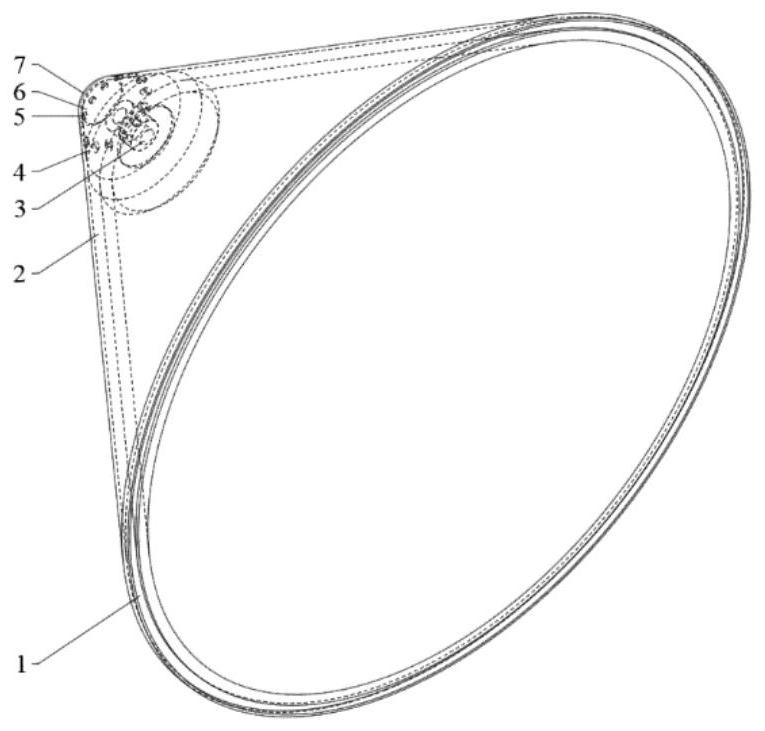

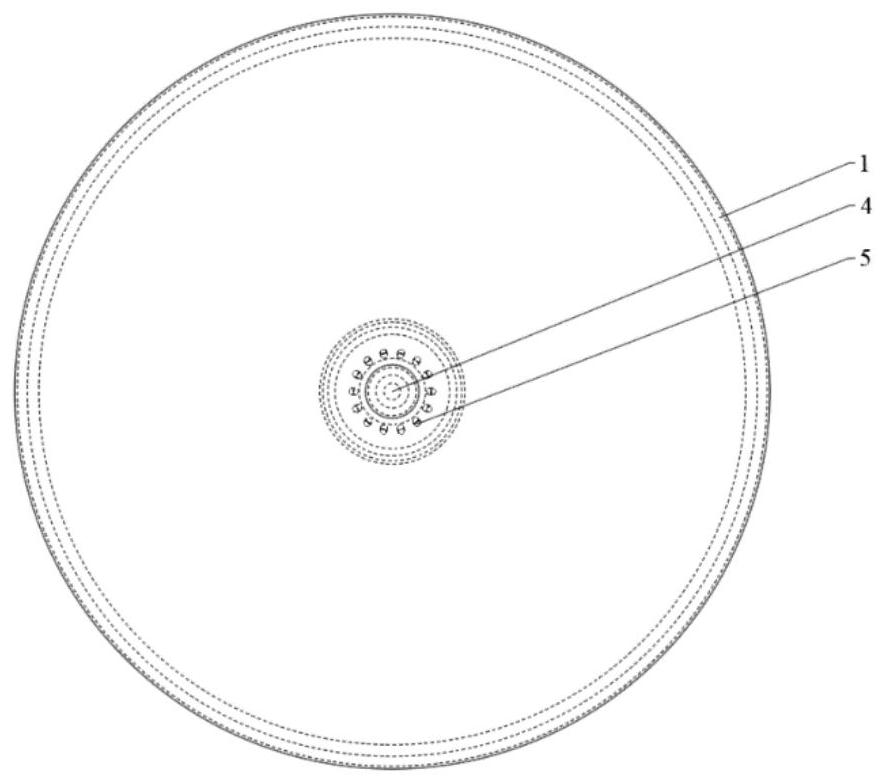

[0028] refer to Figure 1 to Figure 5 , this implementation is a double-wall cowl anti-icing system with an impact-gas film structure on the front edge, which is applied to the front edge impact area of the aero-engine cowling, consisting of hot gas inlet 1, hot gas channel 2, and impact orifice plate 3. The impact hole 4, the air film hole 5, the inner chamber 6 impacted by the front edge of the cap, and the wall surface 7 at the front edge of the cap. A row of cylindrical air film holes is arranged at the front edge of the cap, and the hot gas enters the front edge of the cap through the impact holes to impact the inner cavity, and after impact heat exchange and convective heat exchange with the front edge of the cap, it flows out from the air film holes and the cap heat exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com