A gold and silver cardboard with siphon micropores and its preparation method and application

A technology of gold, silver and paperboard, applied in the direction of chemical instruments and methods, surface covering paper, metal layered products, etc., can solve the problems of affecting production speed, increasing process difficulty, poor ink absorption of gold and silver paperboard, etc., to achieve Improved ink absorption, high ink layer firmness, and small diameter effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Use a coater (Xi'an Taihua Machinery Co., Ltd., QHTB-1200 series coater) to coat a layer of transfer coating on a PET film with a corona value of 35 dyne;

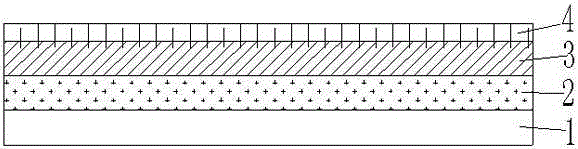

[0044] (2) Use a vacuum metallizer (Leybold PRO-M1300, Germany) to coat the coating surface of the PET film obtained in step (1) with aluminum, the thickness of the aluminum layer is 0.20 μm, which is the dyed aluminum layer 3;

[0045] (3) Use a composite peeling machine (Xi'an Honghe Machinery Co., Ltd., HZFT-1200F) to coat a layer of water-based adhesive on the surface of the dyed aluminum layer 3, and the coating amount is 1.2g / m 2 , and combined with the base paper layer, peel off the PET film after drying, and obtain a silver cardboard with a base paper layer 1, an adhesive layer 2, and a dyed aluminum layer 3;

[0046](4) Use a coater (Xi'an Taihua Machinery Co., Ltd., QHTB-1200 series coater) to coat a layer of water-based transparent varnish on the surface of the dyed aluminum layer 3 in step (3), and t...

Embodiment 2

[0067] The preparation method of the silver cardboard of this embodiment is the same as that of Example 1, the only difference being that before coating the water-based transparent varnish, the surface corona treatment is carried out to the dyed aluminized layer 3 to improve the contact between the siphon microporous layer 4 and the dyed plated layer. The degree of bonding between the aluminum layers 3 .

[0068] The prepared silver cardboard with siphon micropores has a surface tension of 0.70N / m, a micropore diameter of 0.6μm, and a micropore density of 10 7 piece / cm 2 , The micropores run through the siphon microporous layer to 0.07μm below the surface of the dyed aluminum layer, which has a high siphon effect on the ink. The folding endurance of this product is 85 times, and the stiffness is 16.5g / cm 3 , burst resistance 90 (%), surface gloss (75 ° gloss meter) is 60Gs, in line with various color printing packaging requirements.

[0069] The prepared gold and silver car...

Embodiment 3

[0075] (1) Use a coater (Xi'an Taihua Machinery Co., Ltd., QHTB-1200 series coater) to coat a layer of transfer coating on a PET film with a corona value of 46 dyne;

[0076] (2) Use a vacuum metallizer (Leybold PRO-M1300, Germany) to aluminize the coating surface of the PET film obtained in step (1), the thickness of the aluminum layer is 0.30 μm, which is the dyed aluminized layer 3;

[0077] (3) Use a composite peeling machine (Xi'an Honghe Machinery Co., Ltd., HZFT-1200F) to coat a layer of water-based adhesive on the surface of the dyed aluminum layer 3, and the coating amount is 2.4g / m 2 , and compounded with the base paper layer, peel off the PET film after drying, and then paint the aluminum surface to obtain a gold cardboard with a base paper layer 1, an adhesive layer 2, and a dyed aluminized layer 3;

[0078] (4) Use a coater (Xi'an Taihua Machinery Co., Ltd., QHTB-1200 series coater) to coat a layer of water-based transparent varnish on the surface of the dyed alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corona value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com