High heat-dissipation brake disc

A brake disc and high heat dissipation technology, applied in the field of auto parts, can solve the problems of brake disc temperature drop, affect the braking effect, brake heat decline, etc., and achieve the effect of rapid cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

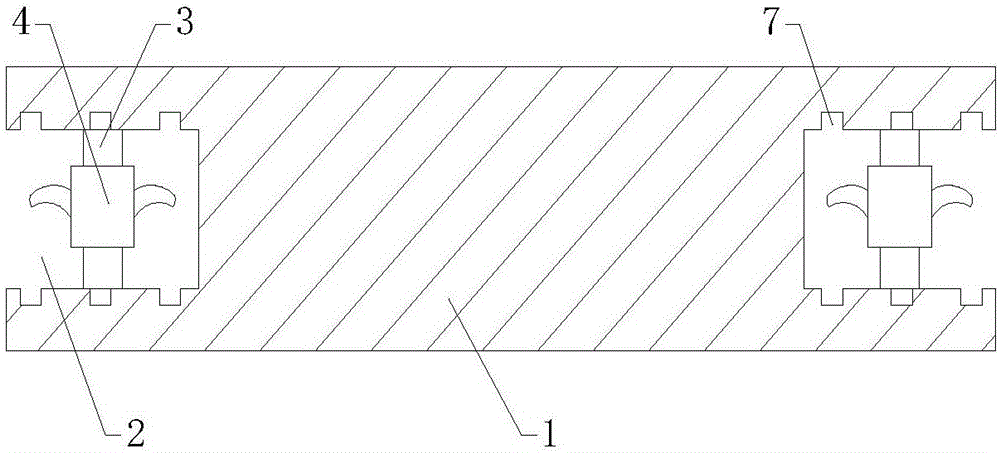

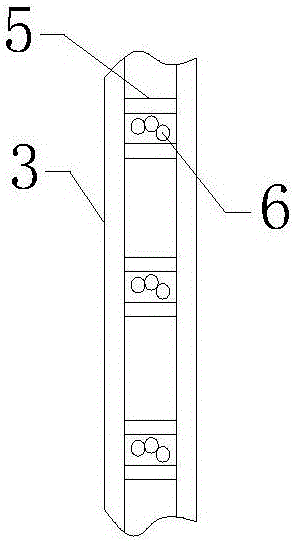

[0012] The present invention will be described in detail below in conjunction with accompanying drawing, as Figure 1-2 Shown: a high heat dissipation brake disc, including a disc body 1, the side wall of the disc body is provided with an annular opening groove 2, and a plurality of self-excited oscillation flow heat pipes 3 are arranged in the opening groove, and the self-excited oscillation The two ends of the flow heat pipe are respectively connected to the top and bottom of the open groove. A plurality of cavity-shaped grids 5 are arranged in the self-excited oscillating flow heat pipe along the pipe extending direction, and fixed particles 6 are arranged in the grid. During the braking process, the friction between the bottom of the disc body and the brake generates heat. On the one hand, the heat can be dissipated through the open groove. On the other hand, the self-excited oscillating flow heat pipe is encapsulated with a working medium, and the working medium forms a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com