Simulation device and test method for oscillating heat transfer performance of cold oil duct in piston

A heat transfer performance and simulation device technology, which is applied in the direction of material thermal development, material thermal conductivity, etc., can solve the problems of evaluating the cooling effect of the internal cooling oil chamber, simplifying the model, increasing the experimental period and cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

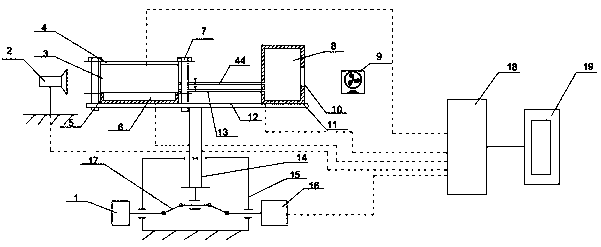

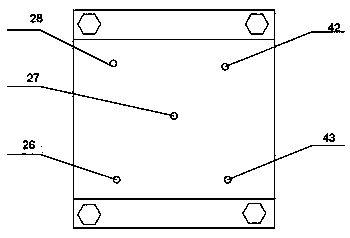

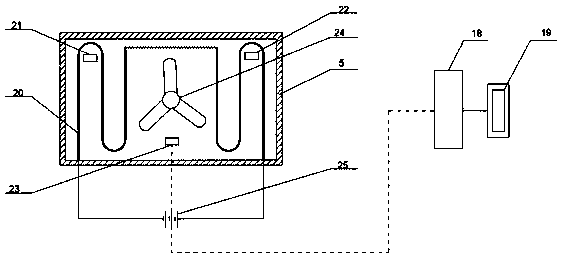

[0031] Embodiment 1: as Figure 1-4 As shown, a simulation device for oscillating heat transfer performance of the internal cooling oil channel of the piston, including a main body oscillating device, a rectangular cavity heating device, a cooling liquid supply and collection device, high-speed photography equipment 2, bolts 7, an installation platform 12, and a control box 18 , computer 19;

[0032] The installation platform 12 is installed on the upper side of the main body oscillating device, and is connected with the main body oscillating device. The rectangular cavity heating device is installed and fixed on one end of the installation platform 12 by bolts 7. The high-speed photography equipment 2 is used to photograph the cooling in the rectangular cavity heating device. In the case of liquid oscillation, the cooling liquid supply and collection device is installed and fixed on the other end of the installation platform 12, and the control box 18 is connected to the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com