Self-excited oscillating flow heat pipe

a heat pipe and self-excitation technology, which is applied in the direction of indirect heat exchangers, lighting and heating apparatus, etc., can solve the problems of significant heat transport performance decline, difficult operation of heat pipes, and inability to secure the space for a large-sized heat sink to be installed right above the central processing unit. achieve the effect of high heat transportation performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

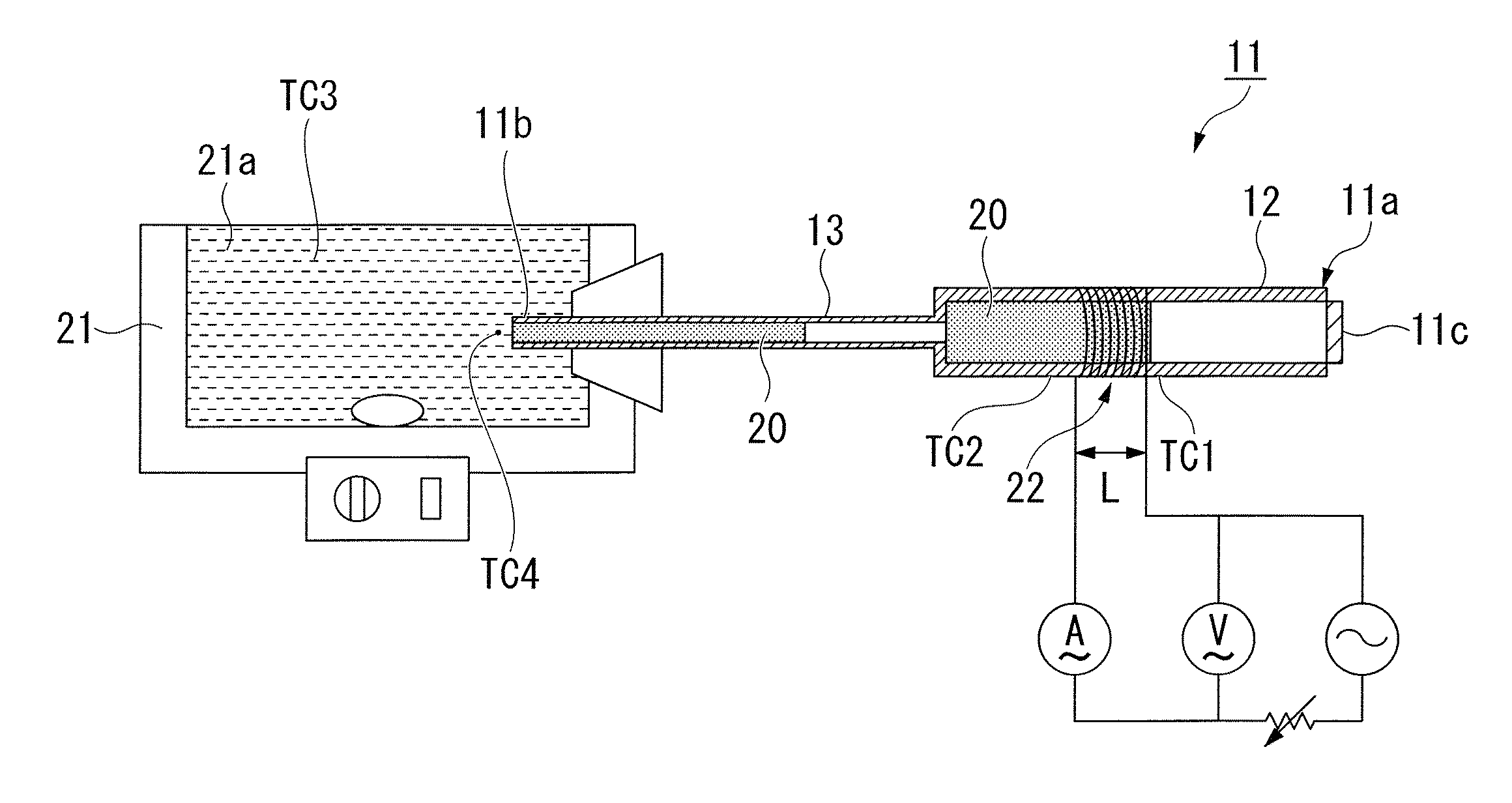

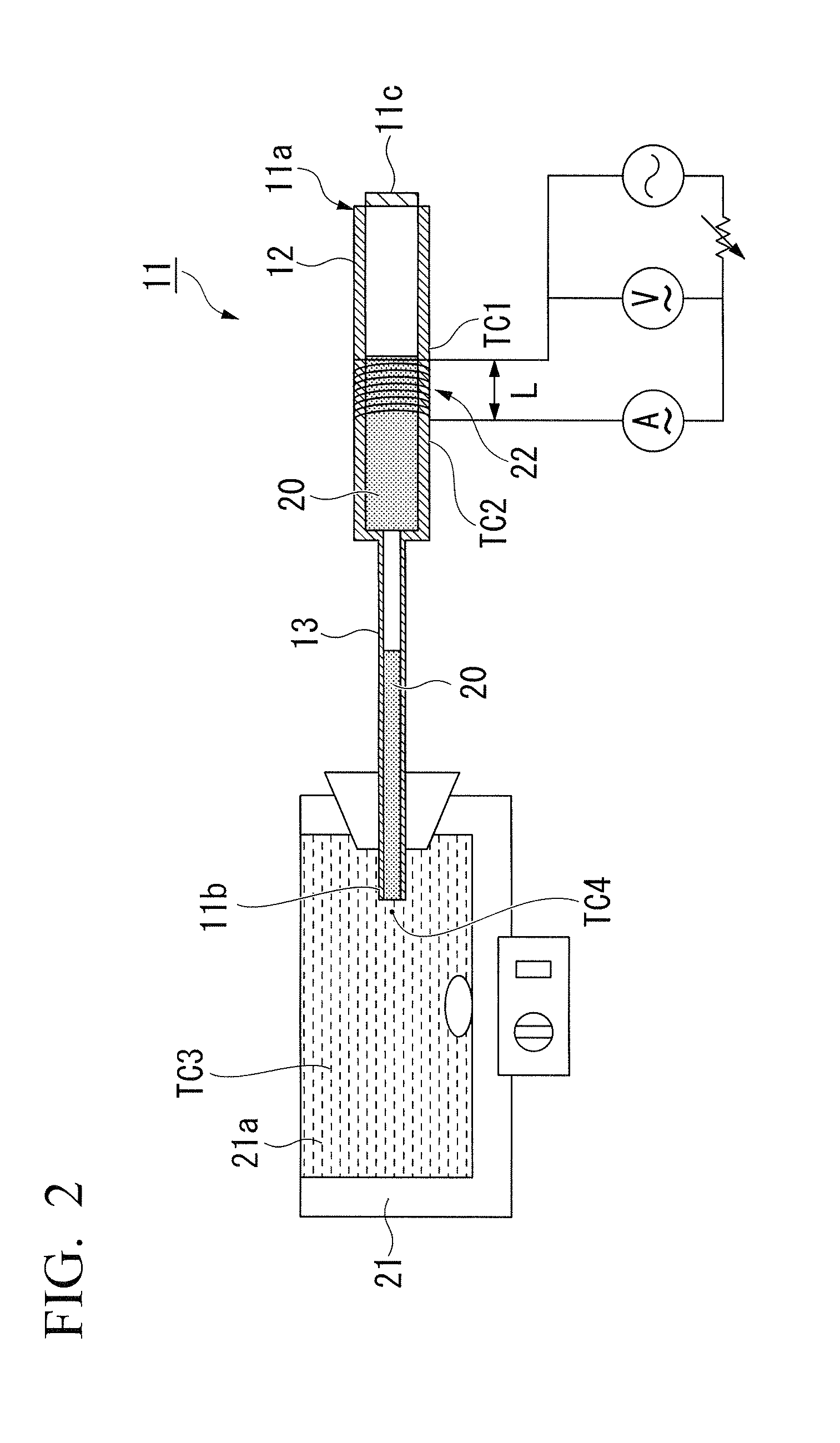

[0067]Characteristics of a heat pipe were evaluated by an experimental device shown in FIG. 2.

[0068]First, a glass tube 13 used as the connection channel 5 made of borosilicate glass with an inside diameter of 2 mm and a length of 250 mm, and a glass tube 12 used as the heating unit 2 made of borosilicate glass with an inside diameter of 5 mm and a length of 150 mm were prepared, and the glass tubes 12 and 13 were fused together. Next, the wick 14 made of a copper net was mounted on the inner wall of the glass tube 12. The wick 14 was mounted at a distance of 100 mm from the fused portion. The portion mounted with the wick 14 was used as the heating unit 2. Next, sealing by a sealing member 11c of which one end 11a is made of borosilicate glass was performed. Next, an open end 11b of the glass tube 13 used as the connection channel was immersed in a water bath 21, and the insides of the glass tubes 12 and 13 were filled with pure water used as the working fluid 20. The heat pipe 11 ...

example 2

[0077]Next, a heat pipe of Example 2 was fixed up similarly to Example 1 except that quartz glass was used as the material for a heating-side pipe and a cooling-side pipe. Then, similarly to Example 1, the relationship between the heat transport rate Q and the effective thermal conductivity λeff in the heat pipe of Example 1 was investigated. The results are shown in FIG. 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com