Self-excitation oscillating-flow heat pipe with netted pipeline

A technology of self-excited oscillation and mesh pipes, which is applied in the field of heat pipes, can solve problems such as pipe blockage and low start-up temperature, and achieve the effects of solving pipe blockage, improving performance, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

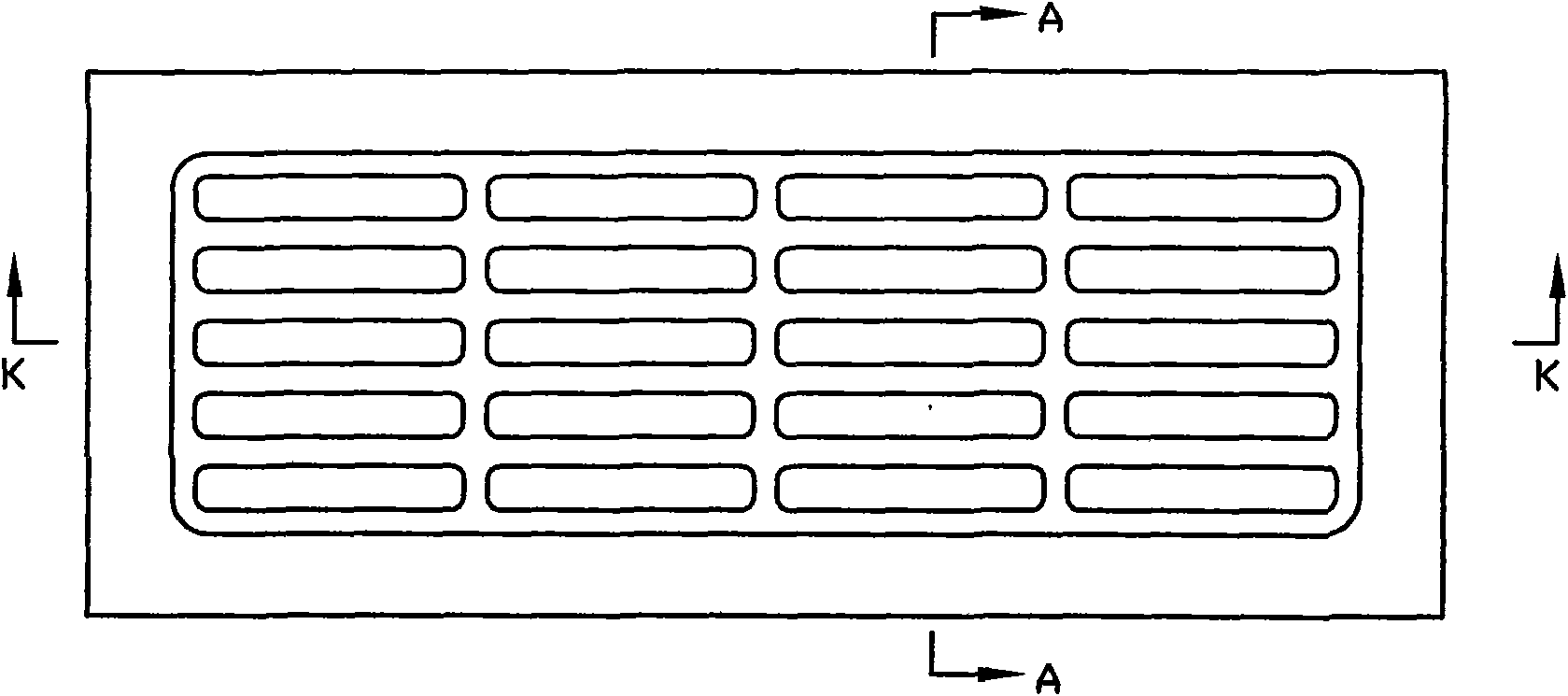

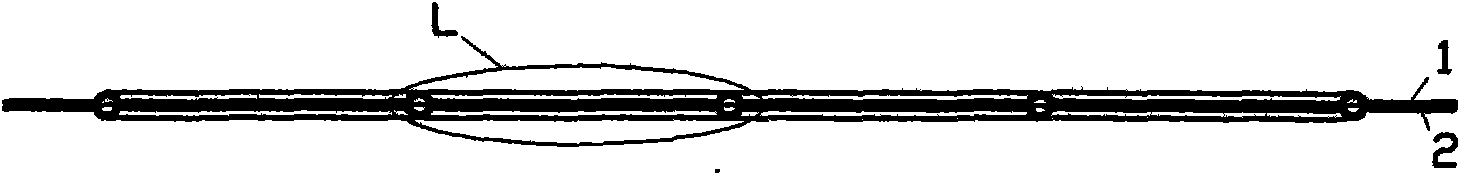

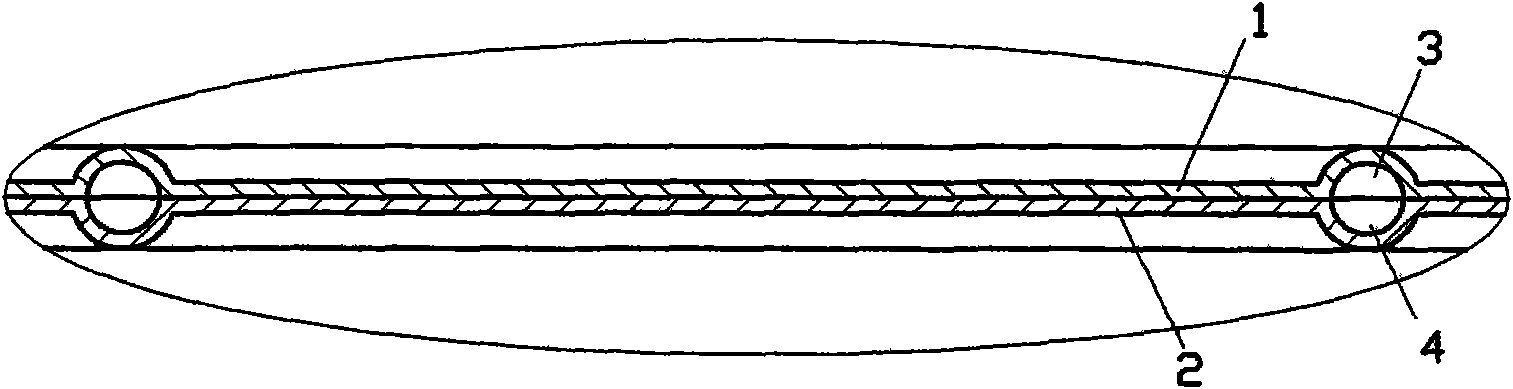

[0034] see Figure 1 to Figure 5 , a self-excited oscillating flow heat pipe with mesh pipes, which is composed of two layers of metal plates 1 and 2, and the two layers of metal plates are integrally formed with grooves 3 and 4, and the grooves 3 and 4 are formed on the two layers of metal plates The spliced surfaces of the self-excited oscillating flow heat pipe form the pipeline for sealing the working fluid. or as Image 6 , Figure 7 As shown, only one layer of metal plate 1 is integrally formed with a groove 3, while the other layer of metal plate 2 has no groove. In the pipeline formed by the grooves 3, 4 (or only the groove 3), the working medium (not shown in the figure) forms a plunger between the liquid phase and the gas phase. The working medium can be water, ethanol, R142b, R123, etc. The two-layer metal plates 1, 2 can be assembled by means of welding, bonding and the like.

[0035] Such as figure 1 As shown, viewed from the direction perpendicular to the...

Embodiment 2

[0037] see Figure 8 to Figure 12 The difference between this embodiment and Embodiment 1 is that the depth of the grooves 3, 4 on the two-layer metal plates 1, 2 is smaller than the thickness of the metal plates where they are located, thus making the two-layer metal plates 1, 2 The side facing the outside can be made into a flat surface, which is more likely to be in close contact with the surface of the object that needs heat transfer.

[0038] Another groove structure of this embodiment can also be as Figure 13 , Figure 14 As shown, only one layer of metal plate 1 is integrally formed with a groove 3, while the other layer of metal plate 2 has no groove.

Embodiment 3

[0040] see Figure 15 , Figure 16 , Figure 17 and Figure 19 , the self-excited oscillating flow heat pipe with mesh pipes is made up of two layers of metal plates, one of which is formed by butt joints of bendable flexible metal plates 5 and non-bendable rigid metal plates 6a, 6b, and the flexible metal plates 5 is connected between two rigid metal plates 6a, 6b, and the other layer of metal plate is formed by the butt joint of bendable flexible metal plate 7 and non-bendable rigid metal plates 8a, 8b, flexible metal plate 7 is connected between two rigid Between the metal plates 8a, 8b. Seen from the cross-section of the metal plates, two layers of rigid metal plates 6a, 8a correspond to splicing, and two layers of flexible metal plates 5, 7 correspond to splicing. The part formed by the two layers of flexible metal plates 5 and 7 can be bent, which makes the self-excited oscillating flow heat pipe easier to bend and has better installation flexibility. The rigid meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com