High shear rate flowing vertically accumulative oscillatory rheology test method and device

A test method, technology of vertical stacking, applied in the direction of measuring devices, flow characteristics, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with reference to the drawings and embodiments. However, the protection scope of the present invention should not be regarded as limited to the following specific embodiments. For those of ordinary skill in the art, without departing from the basic premise of the concept of the present invention, several simple deductions or equivalent substitutions can be made, and these equivalent substitutions will still be regarded as falling within the protection scope of the present invention .

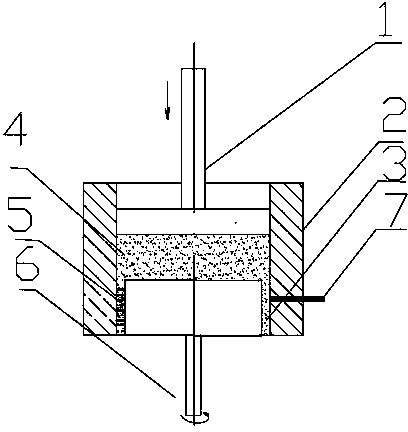

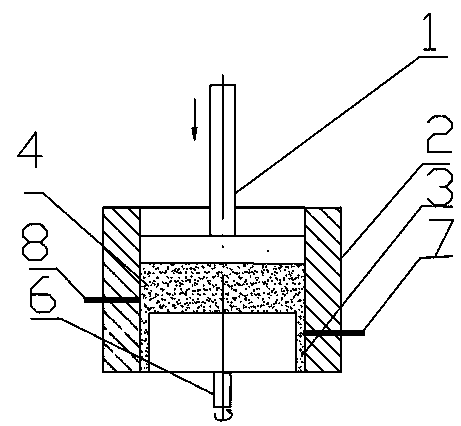

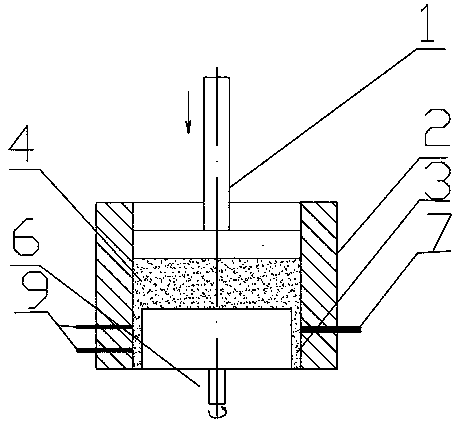

[0021] The core structure of the invented testing device is composed of a plunger 1, a barrel 2 and a core rotor 6, and the barrel contains a material 4. The space enclosed by the barrel 2 and the core rotor 6 is the annular slot die 3. A heating device is installed on the barrel 2 to perform closed-loop control according to the temperature value measured by the temperature sensor 7 to ensure the constant temperature of the material flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com