Abnormal channel array jet flow impact cold plate

A technology of array jets and channels, applied in the direction of cooling/ventilation/heating transformation, to achieve the effect of improving utilization, good temperature uniformity, and preventing mutual interference of turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

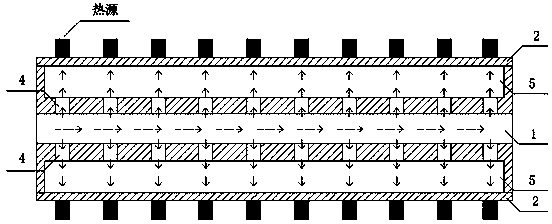

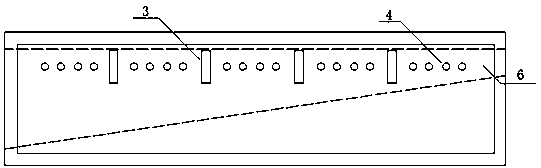

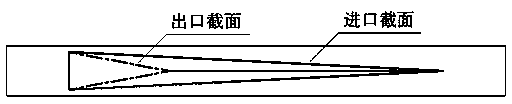

[0011] combine figure 1 , the working principle of the special-shaped channel array jet impinging cold plate of the present invention will be described in detail. From figure 1 It can be seen that the cold plate includes an intermediate layer 1 and an impact chamber 5, the intermediate layer 1 is located between the two impact chambers 5, and is sealed by the cover plate 2 to form a whole. The high heat flux electronic components are respectively arranged on the surface of the cover plate 2 and facing the jet hole 4 . The fluid flows in from one end of the flow channel in the middle layer 1, and then flows out from the other end. When the fluid flows in the flow channel of the middle layer 1 , part of the fluid rushes out from the jet hole 4 and directly hits the inner wall of the cover plate 2 vertically. Since the thickness of the cover plate 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com