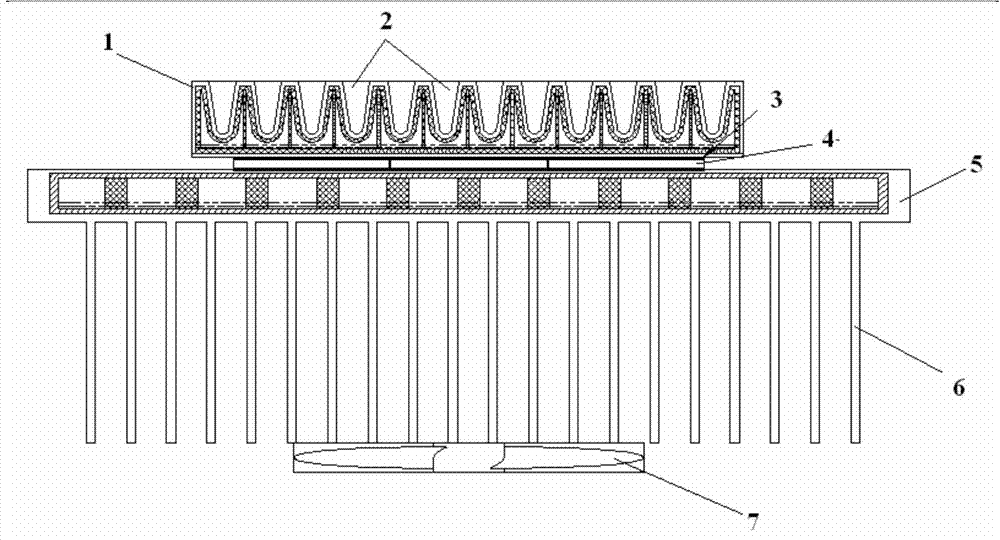

Thermal module for biochemical reaction

A technology of biochemical reaction and vapor chamber, which is applied in the thermal module field of biochemical reaction, can solve the problems of low usability, poor temperature regulation ability, poor heat conduction uniformity, etc., and achieve good heating consistency and good temperature uniformity , The effect of simple technical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

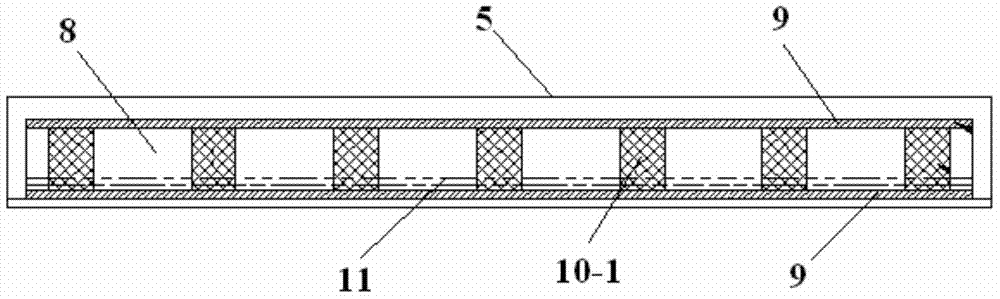

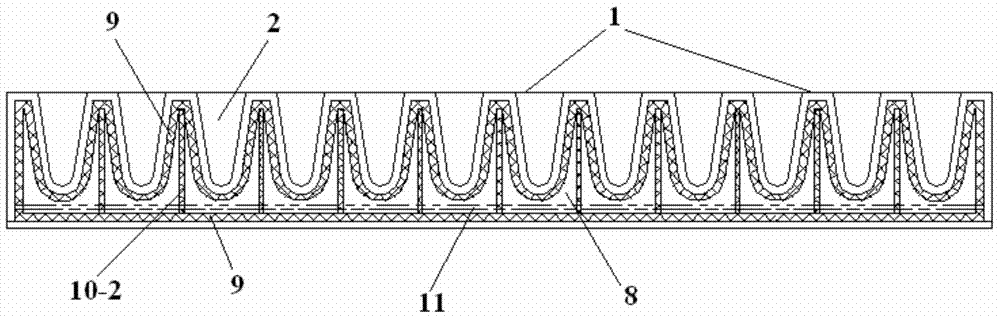

Method used

Image

Examples

Embodiment Construction

[0041] Specific embodiments of the present invention are provided below, and it should be noted that the present invention is not limited to the following specific embodiments, and all equivalent transformations done on the basis of the technical solutions of the present application all fall within the scope of protection of the present invention. It should be noted that the application of the thermal module of the present invention is not limited to thermal modules used for biochemical reactions, and other similar principles or schemes should also be included within the protection scope of the present invention.

[0042] The working principle of the uniform temperature chamber structure is as follows: the cavity of the airtight shell maintains a vacuum state, and the working fluid can use the capillary state to flow between the cavity of the airtight shell, the working fluid return layer and the support column. When the working medium is heated and evaporates, The working flui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com