Conformal countercurrent liquid cooling radiator

A radiator and countercurrent technology, applied in cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve the problems of large thickness of liquid-cooled radiators, insufficient temperature uniformity, unsatisfactory structure, etc. The effect of improving space utilization and good temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with accompanying drawing

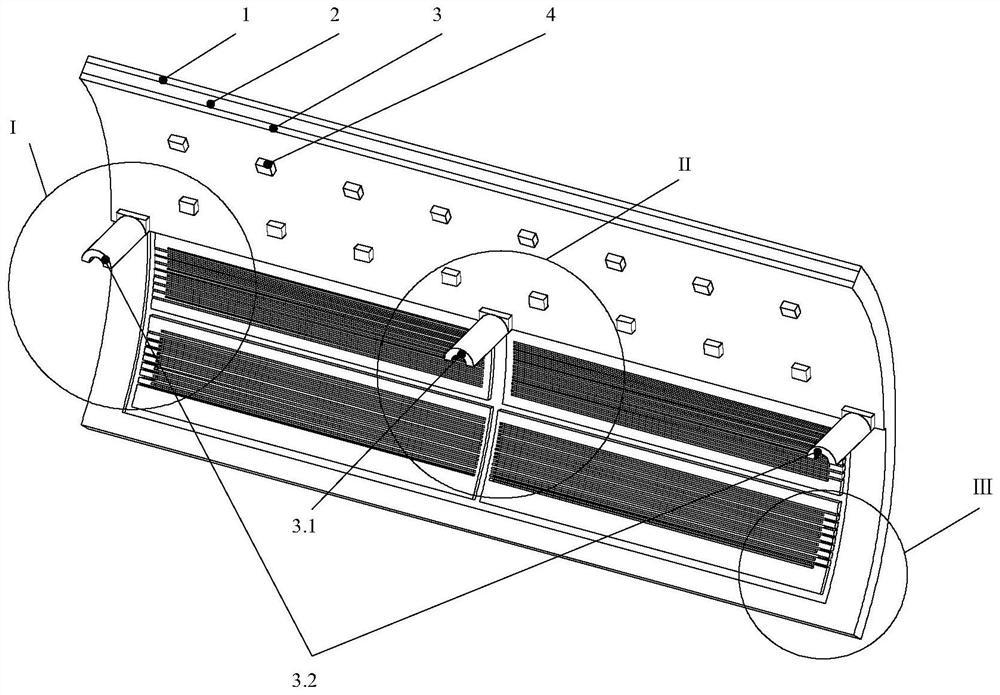

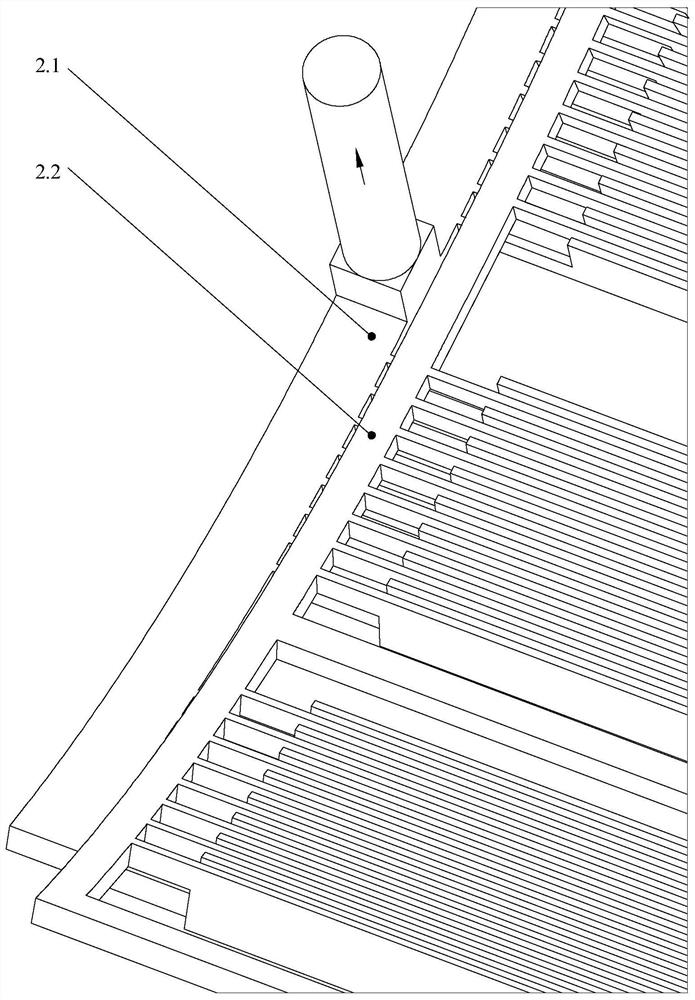

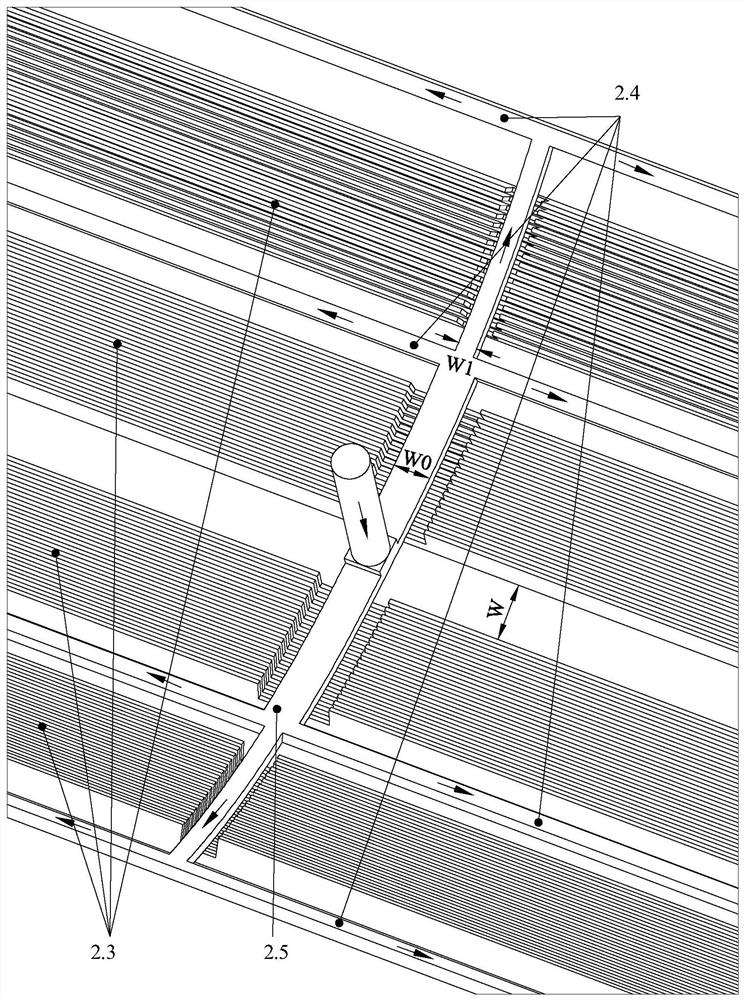

[0024] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5

[0025] A conformal counter-flow liquid cooling radiator of the present invention comprises a cover plate 1, a partition plate 2, and a base plate 3, and is characterized in that the cover plate 1, the partition plate 2, and the base plate 3 are conformal to the electronic equipment; the cover plate The plate 1 is located on the top of the conformal counterflow liquid cooling radiator; the partition plate (2) includes a confluence channel 2.1, a diversion channel 2.2, a counterflow channel 2.3, a transverse channel 2.4, and a longitudinal channel 2.5; the base plate 3 includes an inlet joint 3.1 and Two identical outlet joints 3.2; the confluence channel 2.1 is located directly below the outlet joint 3.2 and communicates with the outlet joint 3.2; the longitudinal channel 2.5 is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com