Heat accumulating type burner for heating furnace

A regenerative and heating furnace technology, applied in the field of heating furnaces and regenerative burners, can solve the problems that the nozzle size is difficult to meet the design requirements, high-temperature flue gas overflow and fire leakage, and cannot be repaired and replaced, etc., to achieve convenience Arrangement and maintenance, good flame organization, compact structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

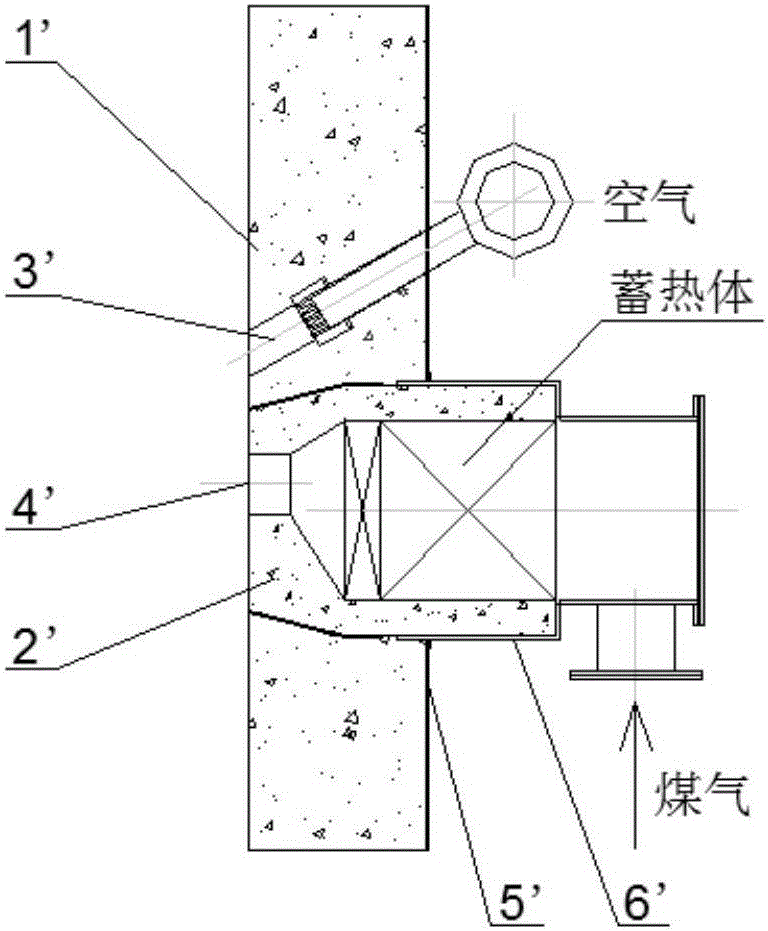

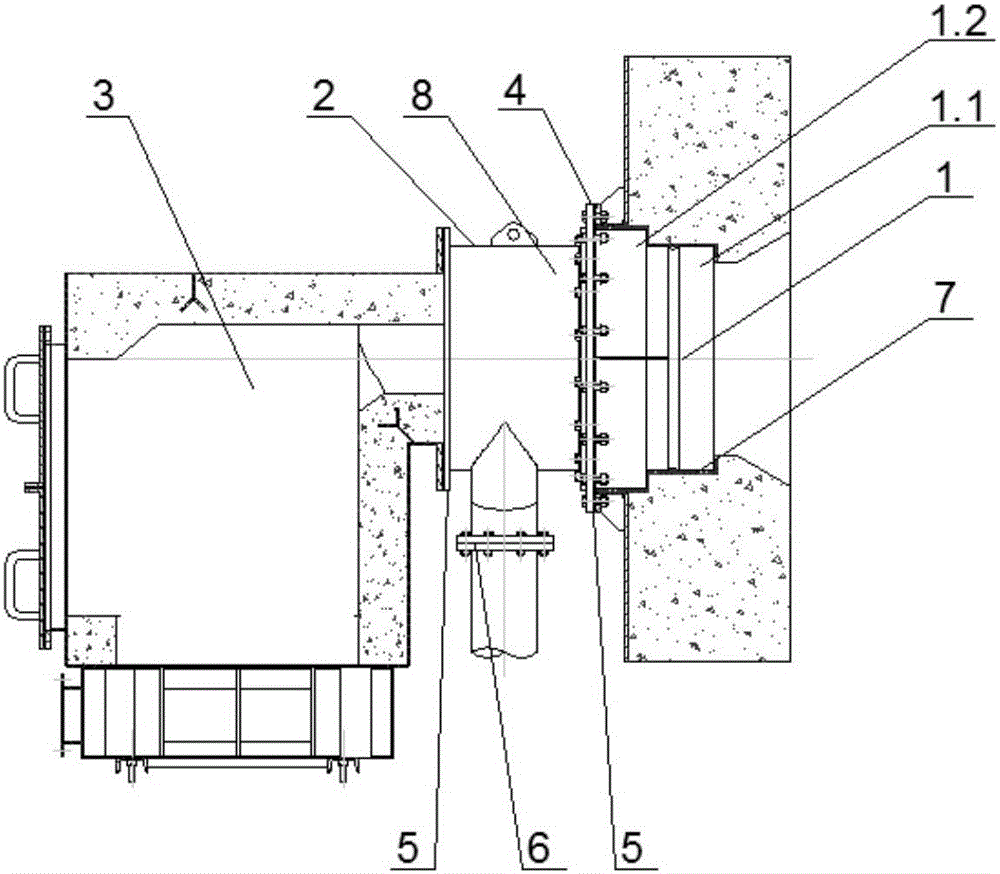

[0033] see Figure 2 to Figure 5 , the present invention discloses a regenerative burner for heating furnace, said burner includes: burner brick part 1, air inlet unit 2, heat storage box 3, set on burner brick part 1 and furnace wall The first flange 4 between them, the second flange 5 arranged on both sides of the air inlet unit 2, the third flange 6 arranged between the air inlet unit 2 and the air duct; the air inlet unit 2 is arranged on the burner Between mouth brick part 1 and heat storage tank 3.

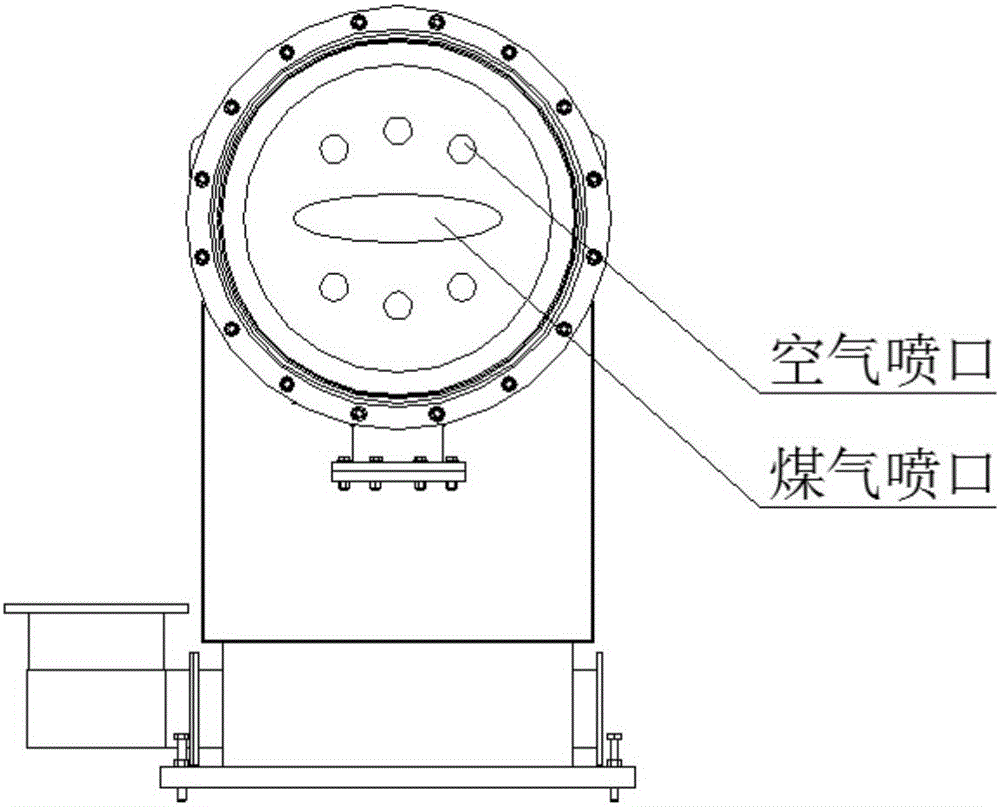

[0034] The burner brick part 1 includes a burner brick 1.1 and a metal shell part 1.2 made of high-temperature and erosion-resistant mullite castable; the two parts are cast together during manufacture, and the air and gas channels are combined in On an independent burner brick, the structure is the same as that of a conventional burner, the inner ring is a gas nozzle, and the outer ring is an air nozzle, which effectively organizes combustion.

[0035] The installation of...

Embodiment 2

[0040] The difference between this embodiment and Embodiment 1 is that in this embodiment, a honeycomb body and a block brick are arranged in the heat storage tank, and the honeycomb body is all made of mullite material, which has a large specific surface area and high heat storage and heat release speed. Fast, low resistance loss, high temperature efficiency, can preheat the gas to 1000 ℃, and recover waste heat to the maximum extent. The blocking brick is made of high alumina brick, which has the characteristics of high temperature resistance, can effectively resist the high temperature heat radiation from the furnace, and protect the honeycomb body.

[0041] A three-way reversing valve is installed on the flue gas and gas pipes in front of the burner, which is used for reversing the gas and flue gas during combustion and heat storage. A thermal resistor is installed on the flue gas branch pipe in front of each burner. When measuring the temperature When the set value is exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com