Method and system for testing thermal diffusion coefficient of solid material

A technology of thermal diffusivity and solid material, which is applied in the field of material thermal property parameter testing, can solve the problems of radial heat flow method heat source uniformity, power fluctuation lateral heat flow loss is not well solved, and contact thermal resistance is difficult to achieve. Guaranteed test accuracy and good temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

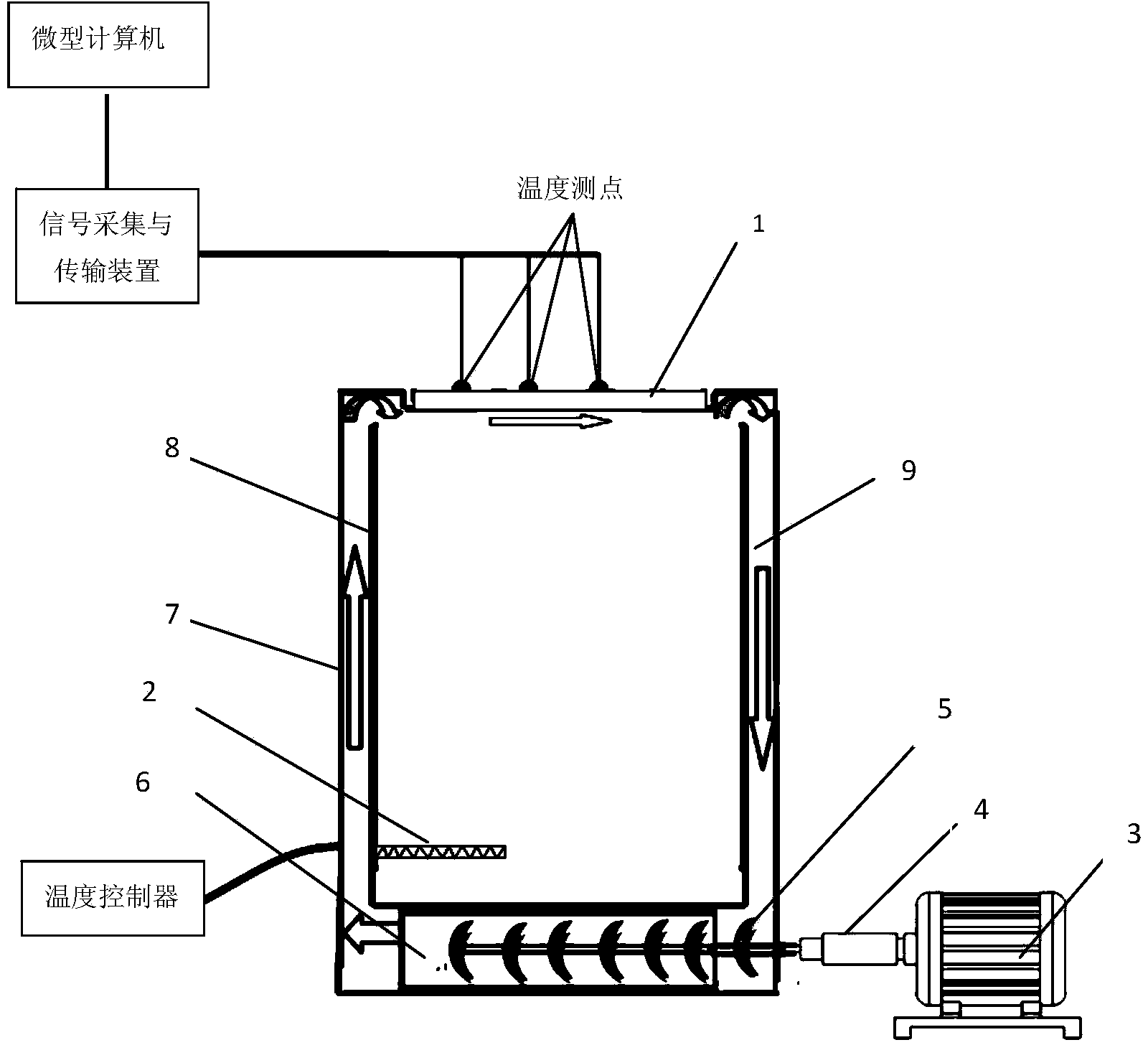

[0026] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

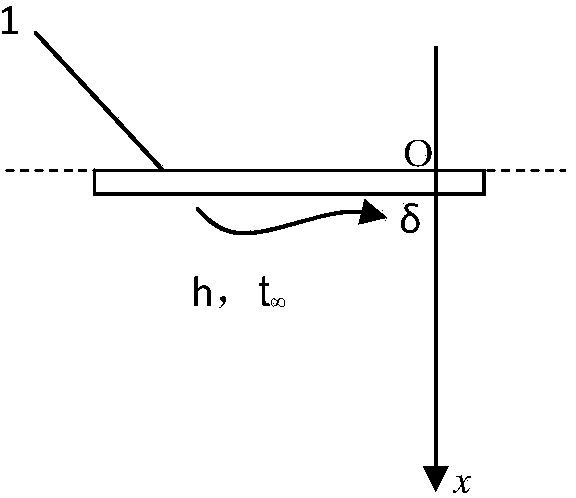

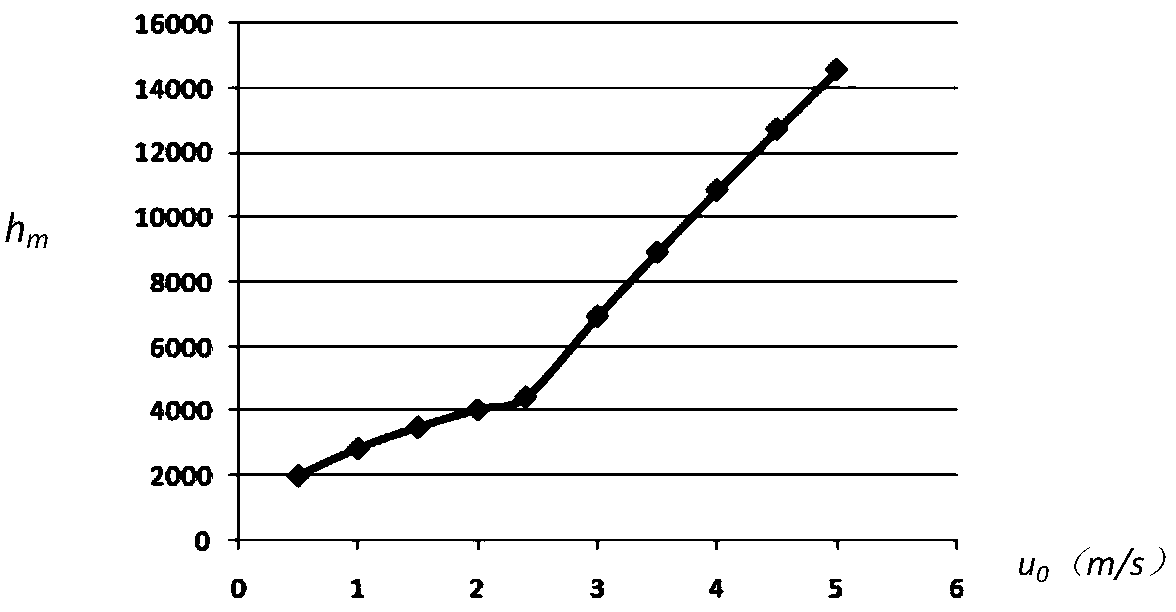

[0027] Such as figure 1 As shown, the flat sample 1, the initial temperature is t 0 , Its one side suddenly and the temperature is t ∞ The other side is in contact with the fluid, and the other side is adiabatic. If the lateral heat transfer is not considered, the heat transfer between the fluid and the solid surface can be regarded as a one-dimensional unsteady heat transfer process under the third type of boundary conditions. The analytical solution is as follows:

[0028] θ ( x , τ ) θ 0 = X n = 1 ∞ 2 sin β n β n + sin β n cos β n cos ( β n x δ ) e - β n 2 Fo - - - ( 1 )

[0029] Where θ—excess temperature, θ=t-t ∞ .

[0030] β n -Beyond equation Series of solutions.

[0031] It is called the Biot number, which represent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com